In modern industrial manufacturing, CNC ball bearing as the core component of mechanical transmission and control, its performance and accuracy are directly related to the operation efficiency and stability of the whole mechanical system. In order to meet the specific needs of different industries and different machinery on bearings, CNC ball bearing customization technology has emerged. In this paper, we will discuss the relevant contents of CNC ball bearing customization, including its importance, customization process, technical characteristics and application prospects.

1.The importance of CNC ball bearing customization

With the continuous progress of industrial technology, the mechanical system of the bearing requirements are increasingly strict. Although the traditional standard ball bearings can meet the general application requirements, but in some specific working conditions, its performance may not be able to fully meet the requirements. For example, in high temperature, high pressure, strong corrosion or high load and other special environments, the life and reliability of standard bearings may be greatly reduced. At this time, CNC ball bearing customization technology is particularly important. Through customization, according to the specific needs of machinery, can choose the most suitable material, heat treatment process, lubrication method and structure form, so as to ensure that the bearing in bad working conditions can still maintain excellent performance and stability.

2.The process of CNC ball bearing customization

The process of CNC ball bearing customization usually includes the following steps:

Demand analysis: First of all, it is necessary to clarify the specific requirements of the machinery on the bearing, including size, load capacity, speed, operating temperature range, corrosion resistance and so on. These requirements will serve as the basis for customized bearings.

Material selection: According to the results of the demand analysis, select the appropriate bearing material. For example, for high-temperature environments, high-temperature-resistant stainless steel or titanium alloys can be selected; for strong corrosive environments, special alloys with excellent corrosion resistance can be selected.

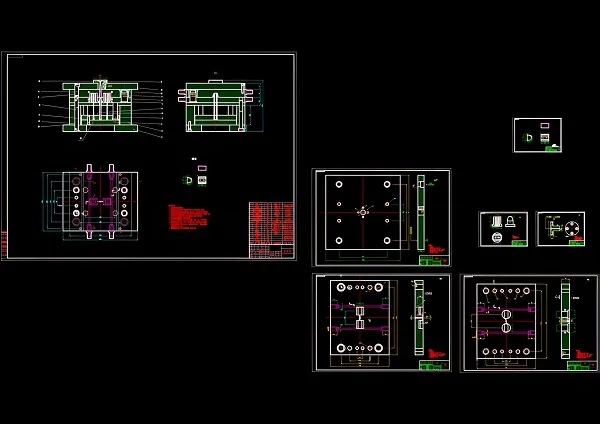

Design optimization: After determining the material, the structure of the bearing needs to be optimized design. This includes determining the size of the inner and outer rings of the bearing, the number of balls, the arrangement, etc., to ensure that the bearing meets the performance requirements at the same time, has the best load carrying capacity and service life.

Manufacturing process: Advanced CNC machine tools and manufacturing processes are used to accurately machine and assemble the bearings. This includes precision turning of inner and outer rings, precision grinding of balls, precise filling of grease, etc.

Quality Inspection: After the manufacturing is completed, the bearings need to undergo strict quality inspection. This includes dimensional measurement, load capacity test, speed test, temperature test, etc. to ensure that the performance of the bearings meets the design requirements.

3. Technical characteristics of CNC ball bearing customization

CNC ball bearing customization technology has the following significant technical characteristics:

High precision: through advanced CNC machine tools and manufacturing process, precise machining and assembly of bearings can be realized, so as to ensure the high precision and stability of bearings.

High reliability: customized bearings can be optimized according to the specific needs of the machinery, thus ensuring that they can maintain excellent performance and stability in a variety of harsh working conditions.

Flexibility: Customized bearings can be flexibly adapted to different working conditions and needs, thus meeting the diverse requirements of mechanical systems.

Economy: Although the initial cost of customized bearings may be higher, but because of its excellent performance and stability, can significantly reduce the mechanical system maintenance costs and downtime, thus bringing long-term economic benefits.

4.The application prospect of CNC ball bearing customization

With the continuous progress of industrial technology and the increasing complexity of mechanical system, the application prospect of CNC ball bearing customization technology will be more and more broad. Especially in aerospace, precision manufacturing, new energy and other fields, the performance and stability of the bearings require very high, customized bearings will become an indispensable key component in these fields. At the same time, with the development of intelligent manufacturing and industrial Internet, CNC ball bearing customization technology will also usher in more innovation and development opportunities.

In summary, CNC ball bearing customization technology is a technological innovation of great significance. It can not only meet the diverse needs of mechanical systems for bearings, but also improve the operational efficiency and stability of mechanical systems. In the future, with the continuous progress of technology and the continuous expansion of application areas, CNC ball bearing customization technology will play a more important role.