Metal stamping dies are indispensable tools in industrial production, especially in the manufacturing of consumer electronics, medical devices, aerospace, new energy vehicles, communications, and industrial automation fields. This article will delve into the uses, advantages, product performance comparisons among multiple companies, specifications, customization processes, and common customization issues of CNC precision metal stamping dies. Additionally, it will highlight the advantages of Xiamen Goldcattle in producing these products.

I. Uses of Precision Metal Stamping Dies

Precision metal stamping dies are primarily used to process metal sheets into specific shapes and sizes of parts. These parts are widely applied in various industries, including but not limited to:

- Consumer Electronics: Housings, buttons, and internal components of smartphones, tablets, laptops, etc.

- Medical Field: Surgical instruments such as scalpels, tweezers, clamps, and components of medical equipment like X-ray machines and MRI scanners.

- Aerospace: Aircraft exterior skins, engine parts, satellite structural components, etc.

- New Energy Vehicles: Battery casings, connectors, chassis, and body panels.

- Communications: Components of network equipment such as routers, switches, and modems.

- Industrial Automation: Control system housings, sensor assemblies, etc.

II. Advantages of Precision Metal Stamping Dies

- High Precision: CNC machining technology ensures high precision in dies, resulting in extremely accurate dimensions and shapes of stamped parts.

- High Efficiency: Stamping processing is highly efficient, easy to mechanize and automate, suitable for mass production.

- Long Lifespan: The die materials are high-quality, and after heat treatment processes, they exhibit excellent wear resistance.

- Low Cost: Stamping processing generally generates no chip waste, requires less material consumption, and does not need additional heating equipment, leading to lower costs.

- Versatility: It can produce parts with a wide range of sizes and complex shapes, catering to various customization needs.

III. Product Performance Comparison Table Among Multiple Companies

Below is a comparison of product performance among three companies in precision metal stamping dies:

| Item | Xiamen Goldcattle | Company A | Company B |

|---|---|---|---|

| Material Selection | High-quality die steels such as S136, NAK80, 718h | Regular die steel | Alloy die steel |

| Precision Control | ±0.01mm | ±0.05mm | ±0.03mm |

| Production Efficiency | High, capable of hundreds of stamps per minute | Moderate | High |

| Die Lifespan | Long, with good wear resistance after heat treatment | Average | Longer |

IV. Specifications of Precision Metal Stamping Dies

The specifications of precision metal stamping dies vary based on specific applications. Common die sizes include:

- Length: Ranges from tens of millimeters to several meters, depending on the size and shape of the parts.

- Width: Similar to length, determined by the width of the parts.

- Height: Often determined by the complexity of the die and the required stamping depth.

Furthermore, the specifications of the die also need to consider factors such as the tonnage of the stamping press, the installation method of the die, and the thickness of the stamping material.

V. Customization Process for Precision Metal Stamping Dies

- Demand Confirmation: Communicate with the customer to clarify the type, quantity, specifications, and special requirements of the die.

- Design and Drafting: Based on customer requirements, a professional designer will create die designs, including die structure and stamping processes.

- Material Selection: Choose suitable die steel materials according to the specific uses and requirements of the die.

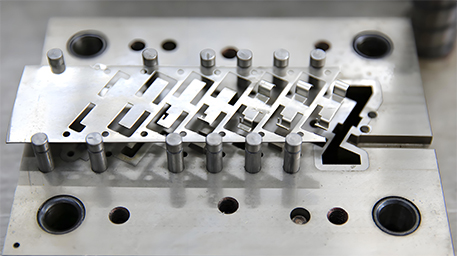

- CNC Machining: Utilize advanced CNC machining equipment and technology for precision die processing, including drilling, milling, grinding, and other processes.

- Heat Treatment: Perform heat treatment on the die to enhance its hardness and wear resistance.

- Quality Inspection: Conduct strict dimensional checks, performance tests, and appearance evaluations on the processed die.

- Die Testing and Adjustment: Conduct die testing on the stamping press, and adjust based on the parameters of the stamped samples to ensure the die meets customer requirements.

- Packaging and Shipment: Package the qualified die and arrange for shipment.

Common Customization Issues

- Material Selection: Customers should select appropriate materials based on the specific uses and requirements of the die, while considering material costs and processability.

- Precision Requirements: Customers need to specify the precision requirements of the die so that designers can fully consider them during the design phase to ensure high die precision.

- Delivery Time: Delivery times can be affected by various factors, such as order volume, material supply, and processing difficulty. When customizing dies, customers should communicate with the manufacturer about delivery times to their production schedules.

- After-Sales Service: Customers should understand the manufacturer’s after-sales service policy, including the warranty period and repair scope of the die, to ensure timely resolution of issues encountered during use.

Xiamen Goldcattle’s Production Advantages

Xiamen Goldcattle Plastic & Metal Products Co., Ltd. has significant advantages in producing CNC precision metal stamping dies:

- High-Quality Materials: Uses high-quality die steel materials such as S136, NAK80, and 718h to ensure high hardness and wear resistance of the die.

- Precision Machining: Equipped with advanced CNC machining equipment and technology to ensure high precision and quality of the die.

- Professional Design: Has a professional design team capable of personalized design based on customer requirements to meet various customization needs.

- Strict Quality Control: Conducts strict dimensional checks and quality assessments at every step of the die processing to ensure it meets customer requirements.

- Comprehensive Services: Provides comprehensive services from design, processing, heat treatment, die testing, adjustment, packaging, and shipment to ensure customer satisfaction.

In summary, CNC precision metal stamping dies play a crucial role in improving production efficiency, reducing costs, and ensuring part quality. With its advantages in high-quality materials, precision machining, professional design, strict quality control, and comprehensive services, Xiamen Goldcattle has become the preferred partner for many customers.