I. Preface

With the rapid development of the manufacturing industry, OEM (Original Equipment Manufacturer) CNC (Computer Numerical Control) machining parts are playing an increasingly important role in various industries. CNC machining technology, with its characteristics of high precision, high efficiency and high flexibility, provides strong technical support for OEM parts manufacturing. This manual aims to introduce the basic concepts, processing procedures, quality control and common problem solutions of OEM CNC Machining Parts, and provide reference and guidance for relevant practitioners.

II. Basic Concepts of OEM CNC Machining Parts

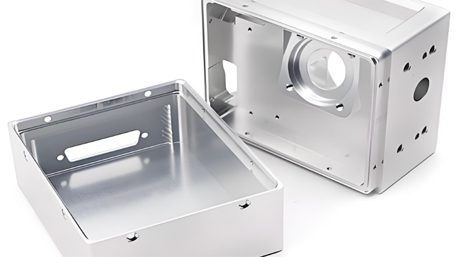

OEM CNC Machining Parts refer to the parts processed by CNC machine tools to meet the specific needs of customers. These parts usually have high precision, complex shapes and customization characteristics, and are widely used in many fields such as aerospace, medical equipment and automotive manufacturing. CNC machining technology realizes the precision processing of parts by controlling the movement of machine tools through computer programs, greatly improving production efficiency and processing quality.

III. Processing Procedures of OEM CNC Machining Parts

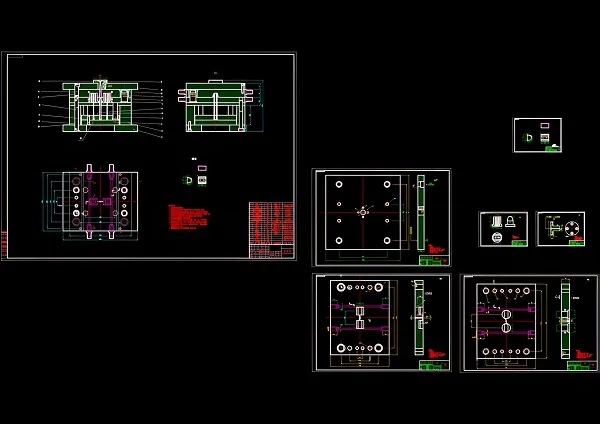

Drawing design and programming: According to customer requirements, design the three-dimensional drawing of the part, and use CAM (Computer-Aided Manufacturing) software for programming to generate the processing path recognizable by the machine tool.

Material selection and preparation: Select the appropriate raw materials according to the usage environment and performance requirements of the part, and carry out pretreatment such as cutting and deburring.

Machine tool setting and debugging: Adjust various parameters of the machine tool according to the processing requirements, such as spindle speed and feed rate, and conduct trial runs to ensure the normal operation of the machine tool.

CNC machining: Put the raw materials into the machine tool, start the processing program, and the machine tool processes according to the preset processing path. During the processing, it is necessary to pay close attention to the operating status of the machine tool to ensure processing quality and safety.

Quality inspection and acceptance: Conduct quality inspection on the processed parts, including dimensional accuracy, surface quality, hardness, etc., to ensure that the parts meet the design requirements.

Subsequent processing and packaging: Carry out subsequent processing on the parts as needed, such as cleaning, rust prevention, coating, etc., and package them for transportation and storage.

IV. Quality Control of OEM CNC Machining Parts

Raw material quality control: Ensure that the raw materials meet the design requirements to avoid unstable processing quality caused by material problems.

Processing process control: Strictly control various parameters in the processing process, such as cutting speed and feed rate, to ensure the stability and consistency of the processing process.

Quality inspection and feedback: Establish a perfect quality inspection system, discover and solve problems in time to ensure that the quality of parts meets the design requirements.

Continuous improvement and optimization: Continuously optimize the processing technology and parameters by collecting and analyzing the data in the processing process to improve processing quality and efficiency.

V. Solutions to Common Problems of OEM CNC Machining Parts

Unqualified dimensional accuracy: Check the accuracy of the machine tool, the wear of the tool, adjust the processing parameters, and optimize the tool path.

Poor surface quality: Optimize the cutting parameters, select the appropriate cutting fluid, and ensure the cleanliness of the machine tool and the tool.

Low processing efficiency: Analyze the bottleneck links in the processing process, optimize the tool path and processing parameters, and improve the utilization rate of the machine tool.

Machine tool failure: Regularly carry out machine tool maintenance and establish a fault early warning mechanism to deal with machine tool failures in time.

VI. Conclusion

OEM CNC Machining Parts, as an important part of modern manufacturing, its processing quality and efficiency directly affect the performance and market competitiveness of products. This manual introduces the basic concepts, processing procedures, quality control and common problem solutions of OEM CNC Machining Parts, aiming to provide practical reference and guidance for relevant practitioners. It is hoped that this manual can help practitioners better master CNC machining technology and improve the processing quality and efficiency of OEM parts.