In the vast field of customized machining, CNC machined parts undoubtedly occupy an extremely critical position. With the continuous development of the modern manufacturing industry, customers for mechanical parts of the growing demand for personalization, the traditional processing methods have been difficult to meet such diverse, high-precision requirements, and CNC machining stands out as a powerful assistant for customized machining.

CNC machining, that is, computer numerical control machining, it is with the help of computer programs on the movement of the machine tool and machining process for precise control. The advantages of this technology in custom machining are first and foremost in its superior precision. Whether it’s complex geometries or tight tolerances, CNC machines can handle them with ease. For example, in the aerospace field of precision parts manufacturing, some parts with special curved contours and tiny size features, CNC machining can ensure that their accuracy reaches the micron or even nanometer level, so as to ensure the performance and safety of the entire aircraft.

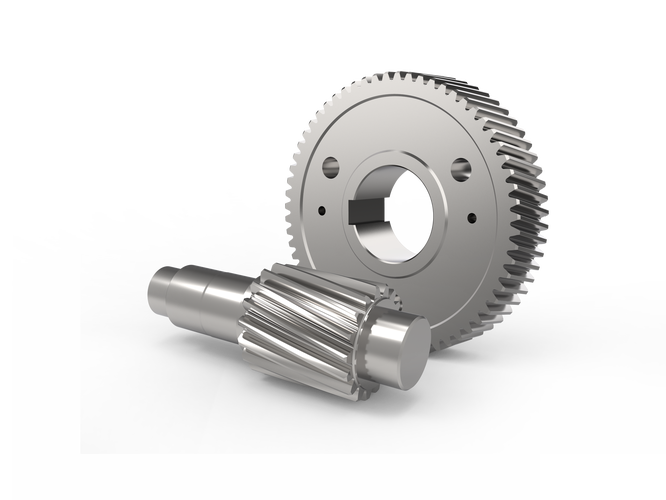

The flexibility of CNC machined parts is also a highlight in the customization process of machining. For different customers put forward different design options, just modify the corresponding processing code in the computer, the CNC machine can quickly adjust the processing path and process parameters, and quickly into production. This is like a highly skilled and can quickly adapt to a variety of repertoire of performers, regardless of the face of what kind of “sheet music” (design drawings), can be accurately “play” (processed parts). Take the automotive tuning industry as an example, for customized engine parts, unique shaped wheels, etc., CNC machining can easily realize the transformation from design concepts to physical products, to meet the pursuit of car owners for personalized driving.

CNC machining also significantly improves the productivity of customized machining. The automated process reduces errors and wasted time caused by manual intervention. The machine tool is able to continuously and efficiently perform cutting, drilling, milling and other machining operations under the command of a preset program. At the same time, the CNC system can monitor the machining process in real time, detecting and dealing with problems such as tool wear and improper workpiece clamping to ensure production continuity and stability. In the batch customized production, this efficiency advantage is more obvious, can guarantee the quality of the premise, significantly shorten the delivery cycle, enhance the competitiveness of enterprises in the market competition.

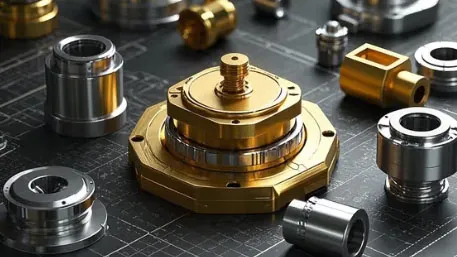

Material adaptability is also an important feature of CNC machining in machining customization. Whether it is common metal materials, such as aluminum alloys, stainless steel, titanium alloys, etc., or various types of engineering plastics, composite materials, CNC machines can be based on its characteristics to select the appropriate tool, cutting speed and feed for processing. This allows customized machining to meet the special needs of different industries for the material properties and functions of parts. For example, some special alloys used in the medical industry made of implantable medical device parts, as well as the electronics industry in the high-precision plastic mold parts, can be accurately manufactured through CNC machining.

From design to finished product, CNC machining in the customized machining throughout, it is not only the realization of customer creativity and demand for technical means, but also to promote the development of modern machinery manufacturing to a higher level of core strength. In the future, with the continuous progress of science and technology, CNC machining technology will continue to innovate and improve for the customized field of machining to open up a broader world, so that more personalized, high-quality mechanical parts from the design blueprint into reality, helping the global manufacturing industry to move towards a new chapter of glory.