CNC machining for wood has emerged as a revolutionary technique in the woodworking industry, offering precise, efficient, and creative possibilities for crafting a wide range of wooden products. Let’s explore this fascinating process from the following aspects:

1. Introduction to CNC Machining for Wood

CNC (Computer Numerical Control) machining for wood involves the use of computer-controlled machines to shape, carve, and drill wood with high accuracy and repeatability. This technology has transformed traditional woodworking, allowing for the production of complex and intricate designs that were previously difficult or time-consuming to achieve by hand.

2. CNC Machines for Woodworking

There are several types of CNC machines specifically designed for woodworking. Router-based machines are commonly used, which use rotating cutting tools to remove material. Laser cutting and engraving machines are also employed for more detailed and delicate work. Additionally, there are CNC lathes for turning cylindrical wood pieces.

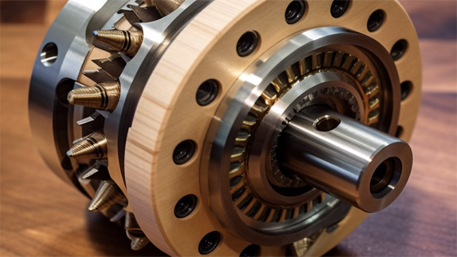

3. Tools and Bits for Wood CNC Machining

The choice of tools and bits is crucial for successful wood CNC machining. Different types of router bits, such as end mills, ball nose bits, and V-bits, are used for various operations like profiling, pocketing, and engraving. The quality and sharpness of the bits affect the finish and precision of the work. Laser cutters use focused laser beams to cut and engrave wood, while CNC lathes require specific turning tools.

4. Design and Software

Before starting the machining process, the design of the wood part is created using CAD (Computer-Aided Design) software. Popular CAD programs allow woodworkers to create 2D and 3D models of their desired projects. The design is then translated into machine-readable code using CAM (Computer-Aided Manufacturing) software, which determines the toolpaths and machining parameters.

5. Materials Suitable for CNC Machining

A wide range of wood species can be machined using CNC technology. Hardwoods like oak, maple, and walnut are often chosen for their durability and fine grain. Softwoods such as pine and cedar are also used, especially for projects where cost or ease of machining is a factor. Engineered wood products like plywood and MDF (Medium Density Fiberboard) are popular due to their consistent properties and affordability.

6. Applications and Products

CNC machining for wood finds applications in various fields. In furniture making, it is used to create unique and custom-designed tables, chairs, and cabinets. Architectural elements such as moldings, balustrades, and decorative panels can be precisely fabricated. Musical instruments like guitars and violins benefit from the accuracy of CNC machining for creating complex shapes and sound holes. Artistic and decorative items like wooden sculptures and relief carvings are also produced using this technology.

7. Advantages of CNC Machining for Wood

The main advantages of CNC machining for wood include high precision and consistency, allowing for exact replication of designs. It enables rapid production, reducing labor-intensive handwork. Complex and intricate designs can be easily achieved, expanding the creative possibilities for woodworkers. The process is also more efficient in terms of material utilization, minimizing waste.

8. Challenges and Considerations

While CNC machining offers numerous benefits, there are also some challenges to consider. The initial investment in CNC machines, software, and training can be significant. Dust collection and ventilation are important for a safe working environment due to the generation of wood chips and dust. Maintenance of the machines and tools is crucial to ensure optimal performance. Also, understanding the properties of different wood types and their behavior during machining is essential to avoid issues like splitting and warping.

9. Safety Measures

When operating CNC machines for wood, safety is of utmost importance. Operators should wear appropriate personal protective equipment such as safety glasses and hearing protection. Machines should be equipped with emergency stop buttons and safety guards. Adequate training on machine operation and safety procedures is necessary to prevent accidents.

10. Future Trends and Developments

The future of CNC machining for wood looks promising. Advances in technology will likely lead to even more precise and faster machines. Integration with other manufacturing processes, such as 3D printing and additive manufacturing, may open up new possibilities for creating hybrid wood products. Additionally, the development of more sustainable and eco-friendly machining practices will be important to minimize the environmental impact.

In conclusion, CNC machining for wood has brought a new level of sophistication and efficiency to the woodworking industry. By understanding its various aspects, from machines and tools to design and applications, woodworkers can take full advantage of this technology to create beautiful and functional wooden products.