CNC machining service has become an indispensable part of modern manufacturing, offering precise and efficient production solutions for a wide range of industries. Let’s explore this essential service from the following aspects:

1. Definition and Overview

CNC machining service refers to the professional manufacturing process where computer numerical control (CNC) machines are utilized to shape and create components from various materials with high accuracy and consistency. This service is employed in the production of parts for industries such as aerospace, automotive, medical, electronics, and more.

2. Types of CNC Machines Used

A variety of CNC machines are employed in the machining service. Milling machines are commonly used for creating complex shapes by removing material from a workpiece. Lathes are ideal for rotational parts, like shafts and cylinders. Drilling machines precisely create holes in the material. Additionally, there are grinding machines for achieving fine surface finishes and electrical discharge machines (EDM) for working with hard and conductive materials.

3. Materials Processed

CNC machining services can handle a wide range of materials. Metals like aluminum, steel, titanium, brass, and copper are frequently processed for their strength and durability. Plastics such as ABS, nylon, and polycarbonate are also used, especially when lightweight or insulating properties are required. Composites and alloys are processed for specialized applications. The choice of material depends on the part’s functional requirements, cost considerations, and the intended environment of use.

4. Precision and Accuracy

One of the key features of CNC machining services is the high level of precision and accuracy they offer. With the ability to control the movement of cutting tools within microns, parts can be manufactured to extremely tight tolerances. This precision ensures that components fit together perfectly and function as intended, reducing the risk of errors and improving the overall quality and performance of the final product.

5. Customization and Prototyping

CNC machining services are highly customizable, allowing for the production of one-off custom parts or small batches of specialized components. This is particularly valuable in prototyping stages where designs need to be tested and refined quickly. The flexibility of the process enables manufacturers to adapt to changes in design specifications easily, reducing time and costs associated with product development.

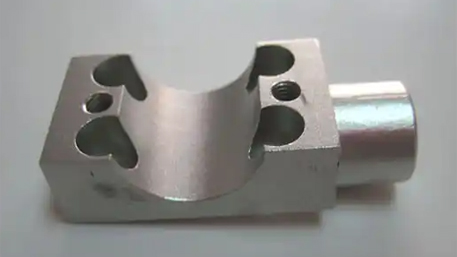

6. Complex Geometries and Features

CNC machines can create complex geometries and intricate features that may be challenging or impossible to achieve with traditional machining methods. Whether it’s internal channels, undercuts, or precise contours, CNC machining can produce parts with complex shapes and structures, expanding the design possibilities for engineers and manufacturers.

7. Quality Control and Inspection

Quality control is an integral part of CNC machining services. Advanced measurement tools such as coordinate measuring machines (CMM) are used to inspect the dimensions and geometries of the machined parts. This ensures that the final products meet the specified standards and requirements. Regular checks during the machining process also allow for early detection and correction of any deviations, minimizing waste and rework.

8. Production Efficiency and Scalability

CNC machining services can be highly efficient, especially for large-scale production runs. Once the programming and setup are completed, the machines can operate continuously with minimal human intervention, increasing output. Additionally, the scalability of the process allows for seamless transition from small batch production to large volume manufacturing, meeting the diverse needs of different projects and industries.

9. Industry Applications

The applications of CNC machining services are widespread. In the aerospace industry, it is used to manufacture critical components like turbine blades and engine parts. The automotive sector relies on CNC machining for engine components, transmission parts, and chassis elements. Medical devices, such as surgical tools and implants, require the precision of CNC machining. Electronics manufacturing uses it for creating intricate enclosures and connectors.

10. Cost Considerations

While CNC machining services offer high precision and quality, the cost can vary depending on factors such as the complexity of the part, material selection, production volume, and lead time. Generally, for small batch production or complex parts, the cost per unit may be higher. However, for larger production runs, the economies of scale can make it a cost-effective option.

11. Technological Advancements and Future Trends

The field of CNC machining is constantly evolving with technological advancements. Improvements in machine tools, cutting tools, and control systems are enhancing the performance and capabilities of CNC machining. The integration of artificial intelligence and machine learning is enabling predictive maintenance and optimization of machining processes. Additionally, the development of hybrid manufacturing techniques that combine CNC machining with additive manufacturing is opening up new possibilities in component design and production.

In conclusion, CNC machining service plays a crucial role in modern manufacturing, providing a reliable and efficient means of producing high-quality, precision parts. Its ability to handle diverse materials, create complex geometries, and ensure strict quality control makes it an essential solution for a wide range of industries, driving innovation and meeting the ever-increasing demands of today’s marketplace.