Polycarbonate (PC) is a thermoplastic engineering plastic with high strength, high transparency, high temperature and impact resistance. Its excellent physical properties and weather resistance make Polycarbonate injection molded parts widely used in many fields.The light transmittance of PC material can be as high as 90% or more, and has excellent UV resistance, which can effectively extend the service life of the product.

1.Xiamen Goldcattle polycarbonate injection molding parts manufacturing process

Raw material preparation

Select the polycarbonate granule that meets the requirements, and add coloring agent, anti-ultraviolet agent, reinforcing agent and other additives as needed.

Dry the raw materials as necessary to remove moisture and ensure the quality of injection molding.

Injection Molding

Polycarbonate injection molding requires high injection and mold temperatures, generally between 260°C and 320°C. The injection is performed at high pressure to fill the molten PC plastic.

High-pressure injection fills the mold with molten PC plastic, ensuring dimensional accuracy and appearance quality of the product through precise control of injection speed, pressure and temperature.

The cooling phase needs to be carried out patiently to prevent deformation or internal stresses in the part.

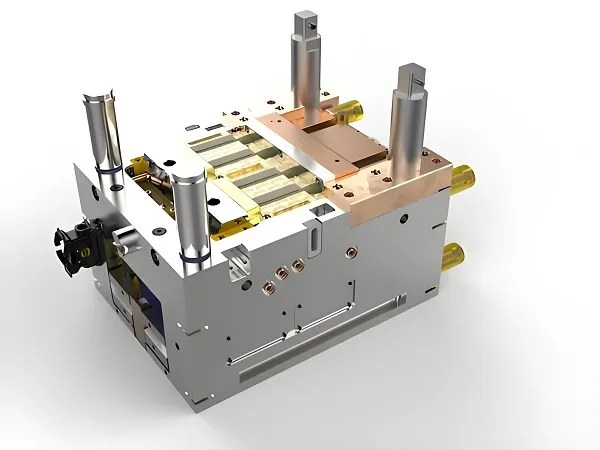

Mold Design

The mold design needs to take into account the high fluidity and high transparency characteristics of polycarbonate to ensure that the surface of the product is smooth and free of bubbles and silver lines.

Reasonable runners and gates are designed to minimize shear heat and flow traces to improve the appearance quality of the product.

Post-processing

Remove burrs, flying edges and other defects on the injection molded parts, and carry out necessary grinding and polishing treatment.

For products requiring higher surface quality, surface treatment processes such as coating and spraying can be carried out.

2.Xiamen Goldcattle Polycarbonate Injection Molded Parts Features

High transparency and weather resistance

Polycarbonate injection molded parts have high transparency and can be used for products that require good visual effects, such as lenses, lighting appliances and so on.

Excellent weather resistance, can be used in outdoor environment for a long time without aging.

High strength and impact resistance

Polycarbonate injection molded parts have high strength and good impact resistance, and can withstand large external forces without rupture.

It is suitable for the occasions that need to withstand mechanical shock or vibration, such as electronic product shells, automobile parts and so on.

Thermal stability

Polycarbonate materials have a high heat distortion temperature, can maintain stable performance in a high temperature environment.

It is suitable for products that need to withstand high temperatures or large temperature changes, such as water heater shells, electrical parts, etc.

Easy processing and molding

Polycarbonate has good processing performance and molding ability, and can be molded by injection, extrusion, blow molding and other processes.

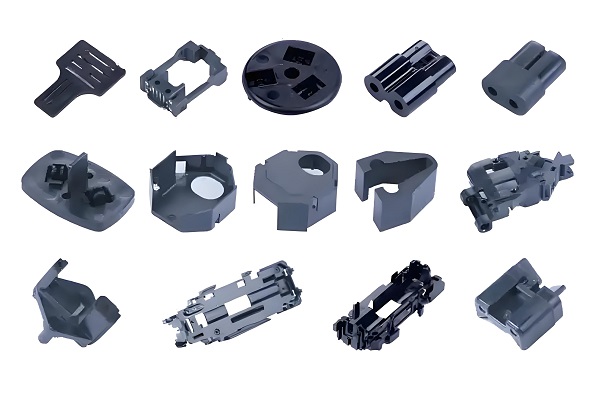

Parts of various complex shapes and sizes can be customized to meet diversified product needs.

3.Application areas of customized polycarbonate injection molded parts

Electronic products

Shells and internal parts of consumer electronic products such as cell phones, tablet PCs, laptops, etc.

Support structures for optical components such as LED displays and backlight modules.

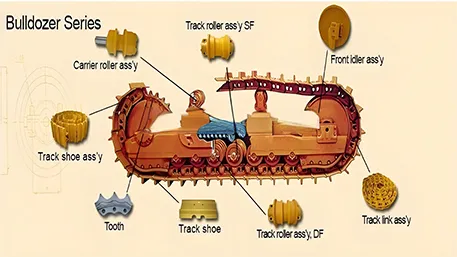

Automotive industry

Automotive lamps, windows, instrument panels, and other parts that utilize the high transparency and weather resistance of polycarbonate.

Interior parts such as seat components and door handles require high strength and impact resistance.

Medical Devices

Parts such as medical device housings, surgical instruments, and syringes require non-toxicity and ease of cleaning.

Optical medical devices such as eyeglass lenses and contact lenses.

Packaging and Containers

Transparent packaging bottles and containers for food, pharmaceuticals and cosmetics.

Aquariums, aquarium equipment and other products requiring high transparency and impact resistance.

Construction and Building Materials

Transparent acoustic panels, heat-insulating panels, and other building materials.

Encapsulation materials for solar panels that utilize the light transmission and weather resistance of polycarbonate.

Xiamen Goldcattle Custom Polycarbonate Injection Molded Parts FAQ

Is the material environmentally friendly?

Yes, the polycarbonate material itself is environmentally friendly, but in certain applications such as food packaging, it is required to meet specific environmental standards and certifications.

What is the quality of the product?

The quality of custom polycarbonate injection molded parts depends on the quality of the raw materials, the production process and the level of equipment. Choosing reliable suppliers and strictly controlling the production process are key to ensuring product quality.

How long is the customization cycle?

Custom cycle time varies depending on the complexity of the product, mold making time and production volume. Typically, it can take anywhere from a few weeks to a few months from design to production completion.

What are the starting quantities?

Starting quantities depend on the supplier’s minimum production requirements. Some suppliers may have lower starting quantities to accommodate small customization needs.

Do you offer personalization?

Yes, polycarbonate injection molded parts support personalization. The shape, size, color and function of the product can be designed according to customers’ specific needs.