CNC milling prototype technology is a crucial technology in modern manufacturing industry, which plays an important role in multiple fields such as product development, teaching, and industrial production. The following is a detailed academic sharing of this technology.

I. The Basic Concept of CNC Milling Prototype Technology

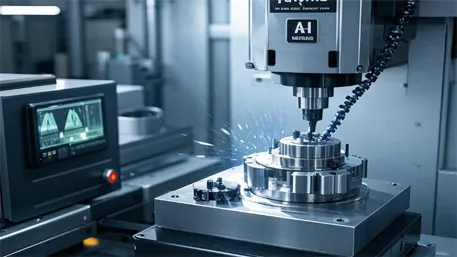

Computer Numerical Control (CNC) milling prototype technology is a processing method controlled by a computer, gradually removing the workpiece material through a rotating multi-edge cutting tool to produce custom-designed parts. This technology can handle various materials such as metals, plastics, glass, and wood, and can manufacture various complex and custom-designed components.

II. The Development History of CNC Milling Prototype Technology

Early Applications

In the early days, CNC milling technology was mainly used in the traditional mechanical processing field to produce relatively simple parts. With the continuous development of computer technology, CNC milling technology has gradually achieved automatic control, improving processing accuracy and efficiency.

Technology Integration

In recent years, in order to overcome the limitations of a single processing technology, researchers have begun to combine rapid prototyping technology with CNC milling technology. For example, Fused Deposition Modeling (FDM) in rapid prototyping (RP) technology can be combined with CNC milling technology to form a hybrid processing technology. This hybrid technology can give full play to the advantages of both technologies and improve the manufacturing accuracy and complexity of parts.

III. The Advantages of CNC Milling Prototype Technology

High-Precision Processing

CNC milling prototype technology can achieve high-precision processing and can meet the manufacturing requirements of various complex parts. For example, through the accuracy test of a three-axis CNC milling machine, it was found that the deviations in the X-axis, Y-axis and Z-axis were 0.033mm, 0.102mm and 0.063mm respectively, and the flatness of the worktable was 0.096mm. These deviation values are all within the tolerance range of the ISO 2768 standard.

Material Diversity

This technology can handle a variety of materials, providing more choices for product development in different fields. Whether it is metal, plastic or other materials, CNC milling prototype technology can carry out effective processing.

Customized Design

Due to computer control, CNC milling prototype technology can be customized according to the specific needs of customers. Designers can design the three-dimensional model of the part through CAD software, then generate the processing code through CAM software, and finally process it by the CNC machine tool to achieve highly personalized production.

IV. The Application Fields of CNC Milling Prototype Technology

Product Development

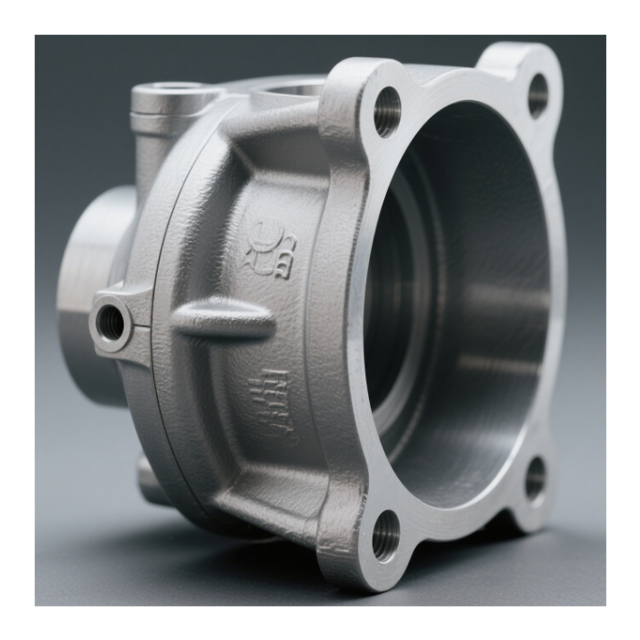

At any stage of the product development cycle, rapid prototyping (RP) technology can be used to manufacture parts or subassemblies. And CNC milling prototype technology can carry out high-precision processing in the later stage of product development to ensure the quality and performance of the product. For example, when designing a new product, RP technology can be used to quickly manufacture the prototype for testing and verification first, and then CNC milling technology can be used for fine processing to produce the final product.

Teaching Material Development

CNC milling prototype technology can also be used as teaching materials for the development of computerized manufacturing courses and industrial machinery automation courses. Teachers can show students the process and principle of mechanical processing by operating the CNC machine tool in practice, improving students’ practical ability and innovative thinking.

Industrial Production

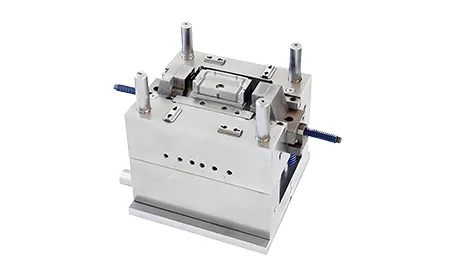

In industrial production, CNC milling prototype technology can be used to manufacture various complex parts and molds. For example, in the fields of automotive manufacturing, aerospace, electronic equipment, etc., CNC milling prototype technology has wide applications. It can improve production efficiency, reduce production costs, and ensure the quality and reliability of products.

V. The Challenges and Future Development Trends of CNC Milling Prototype Technology

Challenges

Control System Integration: Integrating different processing technologies onto one platform requires solving the problem of control system integration. Different processing technologies may require different control parameters and operation processes. How to achieve unified control and management is a challenge.

Alignment Accuracy During Process Changes: In the hybrid processing process, maintaining the alignment accuracy between different processes is crucial. For example, when combining FDM technology with CNC milling technology, it is necessary to ensure the position accuracy of the two processes during the processing to ensure the quality of the part.

Future Development Trends

Intelligent Processing: With the development of artificial intelligence and machine learning technology, CNC milling prototype technology will gradually achieve intelligent processing. By real-time monitoring and analyzing the data during the processing, the processing parameters can be automatically adjusted to improve processing efficiency and quality.

Integration with Information Technology: According to the concept of Industry 4.0, combining information technology with CNC milling prototype technology can realize the digital and intelligent management of the production process. For example, through the Internet of Things technology, remote monitoring and maintenance of equipment can be realized to improve production efficiency and reliability.

High-Precision and High-Speed Processing: In order to meet the continuously improving product quality requirements, CNC milling prototype technology will continuously improve processing accuracy and speed. For example, by adopting technologies such as high-speed / high-power spindles and high-feed / high-acceleration machine tool drives, the processing time can be greatly shortened and the production efficiency can be improved.

In conclusion, CNC milling prototype technology has an important position and role in modern manufacturing industry. With the continuous development and innovation of technology, CNC milling prototype technology will continue to overcome challenges and achieve higher-precision and more efficient processing, making greater contributions to the development of various fields.