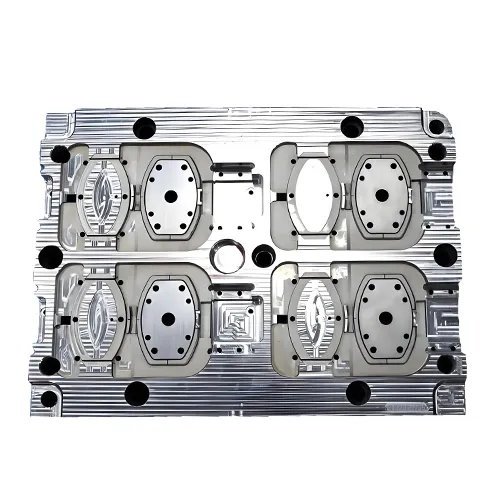

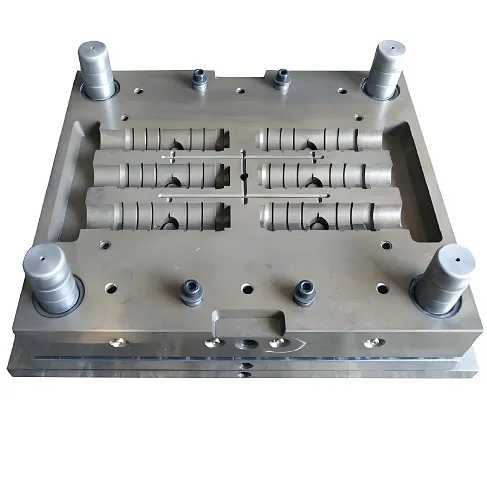

Customized precision optical grade multi-cavity injection mold

Place of Origin : Xiamen,China

Name : Injection Molding Abrasives

Model : MJ-03

Material : Steel/stainless steel/aluminum alloy, etc.

Application : Plastic bottles/electronic parts/automotive parts, etc.

Mold Usage : Injection Tools

Mold Cavity : 1 cavity or customized

Mold Runner : Hot Runner/Cold Runner

Mold Material : 13/P20/718/2314 etc.

Mould life : 500,000 to 3 million sheets or customized

Mold 3D type : STP/STEP/XT/IGS etc.

Customizable : Yes

Mold Spare Parts : Injector / Nozzle / Ring / Seal / Heater etc.

Description

In a rapidly changing market environment, shortening time to market is critical to staying competitive. With innovative injection mold technology, our company is committed to helping customers significantly shorten the mold development cycle and improve production efficiency. Below are our product details, showing how we are driving industry development through technological innovation:

1. Innovative technology to accelerate mold development

●Efficient design: Use the latest CAD/CAM software to achieve fast and accurate mold design and reduce the design cycle.

●Intelligent simulation: Use advanced CAE analysis tools to simulate the mold structure and injection molding process to discover and solve problems in advance.

●Rapid prototyping: quickly produce mold prototypes through 3D printing technology to shorten verification time and ensure design accuracy.

2. Precision processing to ensure mold quality

●High-precision CNC processing: Using a precision CNC machining center to ensure the processing accuracy and surface quality of the mold.

●High-quality materials: Use high-performance mold steel to improve the durability and stability of the mold.

●Strict quality inspection: Implement strict quality control processes to ensure that each mold reaches industry-leading standards.

3. One-stop service to simplify production process

●Project consulting: Provide customers with professional mold design and production consulting services to ensure the smooth progress of the project.

●Quick response: Establish a quick response mechanism to promptly solve problems encountered by customers during the mold development process.

●After-sales support: Provide comprehensive after-sales technical services, including mold repair, maintenance and optimization suggestions.

4. Application fields, wide coverage

Our innovative injection mold technology is suitable for a variety of industries, including:

●Electronic and electrical appliances: Provide quickly customized injection molds for electronic products.

●Automobile manufacturing: Provide efficient and reliable mold solutions for automobile parts.

●Medical equipment: Provide high-quality injection molds for precision medical devices.

●Consumer products: Provide quick response mold design and manufacturing services for various consumer products.

Choosing XIAMEN GOLDCATTLE’s innovative injection mold technology means choosing faster time to market, higher production efficiency and better product quality. Contact us now and let us work together to push your product to market quickly!