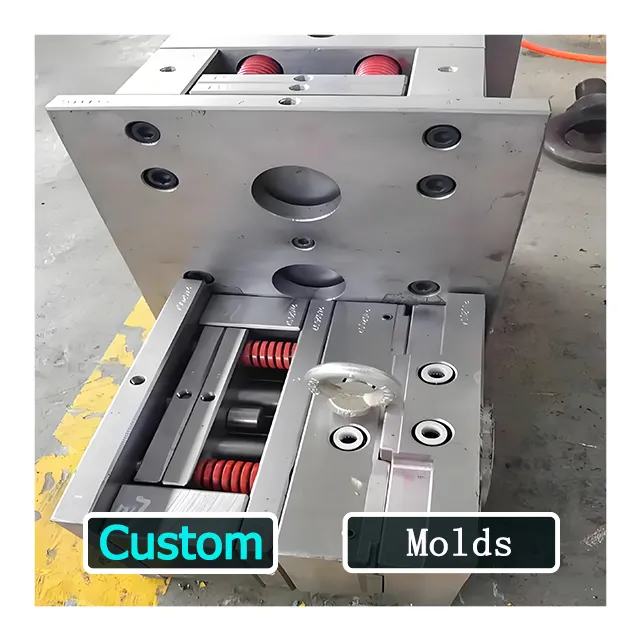

Custom Precision Plastic & Rubber Silicone Mold Injection Manufacturers

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : IM-77

Product Material : Steel

Product : plastic mold

Product Name : custom plastic mold

Shaping Mode : Plasitc Injection Mould

Material : Stainless Steel

Color : Customized Colors

Size : Customized Size

Service : OEM ODM Customized

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Certification : ISO9001

Tolerance : +/-0.005mm

MOQ : 1piece

Description

I. Service Overview

In today’s highly competitive market environment, high-quality molds are the key to the success of products. We are proud to launch for you the custom precision plastic, rubber and silicone mold service, dedicated to meeting your demands for high precision, high performance and unique design of molds.

II. Custom Service Features

Personalized Customization Plan

Deeply understand your product concepts and functional requirements, and closely cooperate with you at every step from the initial concept to the final mold design.

Whether it is a complex geometric shape, a special texture effect or a unique structural design, we can accurately achieve it.

Professional Design Team

An elite team composed of senior mold designers and engineers, with rich industry experience and professional knowledge.

They not only master the principles and techniques of mold design, but also keep up with the industry development trends to provide you with innovative and practical design solutions.

Maintain close communication with you, respond to your needs and feedback in a timely manner, and ensure that the design plan fully meets your expectations.

Material Diversity

Provide you with a wide range of material choices, including various high-performance plastics (such as high-strength polyethylene, chemically resistant polypropylene, etc.), rubbers of different hardness and elasticity (such as the flexibility of natural rubber, the wear resistance of synthetic rubber, etc.) and silicone materials of various characteristics (such as high-temperature-resistant silicone, high-insulation silicone, etc.).

Recommend the most suitable materials for you based on the usage environment, performance requirements and cost budget of your products to ensure that the mold meets the functional requirements while achieving the best cost performance.

III. Service Advantages

Precision Manufacturing

Equipped with the most advanced processing equipment and high-precision measuring instruments, it can achieve micron-level processing accuracy.

Strictly control the tolerance range of the molds to ensure that the size and shape of each part are accurate and error-free, thereby ensuring the high consistency and stability of the produced products.

Pay attention to the detail processing of the molds, such as the optimized design of the runner and the reasonable layout of the cooling system, to improve production efficiency and product quality.

Strict Quality Control

Established a perfect quality management system, and there are strict quality standards and inspection procedures for each link from mold design, raw material procurement, processing and manufacturing to finished product inspection.

Adopt advanced detection technologies, such as coordinate measuring machines, non-destructive testing equipment, etc., to conduct comprehensive detection on the size accuracy, surface quality and mechanical properties of the molds.

For any quality problems found, we will promptly take corrective measures to ensure that the molds delivered to you are of excellent quality and impeccable.

Efficient Delivery

Optimize the production process, adopt project management methods, and accurately control and track the production progress of the molds.

Establish long-term and stable cooperative relationships with high-quality raw material suppliers to ensure the timely supply of raw materials.

Have an efficient team collaboration mechanism, and all departments closely cooperate to complete the manufacturing and delivery of the molds in the shortest time to help you seize the market opportunity.

IV. Production Process

CAD/CAM Design

Use advanced computer-aided design (CAD) software for three-dimensional modeling and mold structure design to visually display the appearance and internal structure of the mold.

Through computer-aided manufacturing (CAM) software, the designed model is transformed into a numerical control processing program to achieve automatic processing and improve design efficiency and accuracy.

Use simulation analysis software to simulate the injection molding process of the mold, predict possible defects in advance, and optimize the mold design and process parameters.

Electrical Discharge Machining (EDM)

For complex shapes and high-precision parts that are difficult to be achieved through conventional cutting processing, such as the cavity and core of the mold, electrical discharge machining technology is adopted.

This technology can erode metal materials through high-temperature discharge without contacting the workpiece, achieving fine and complex shape processing and ensuring the accuracy and surface quality of the mold.

Polishing and Surface Treatment

Adopt fine polishing process to remove processing marks and flaws on the mold surface to make the surface finish reach the mirror level.

Carry out surface coating treatment, such as hard chrome plating, nitriding, etc., to improve the wear resistance, corrosion resistance and demolding performance of the mold and extend the service life of the mold.

V. Processing Equipment

High-Precision CNC Machining Center

Have multiple high-precision CNC machining centers that can achieve multi-axis linkage processing to meet the processing requirements of complex shape molds.

The equipment has a high-speed cutting function, which greatly improves the processing efficiency while ensuring the processing accuracy and surface quality.

Precision Electrical Discharge Machine

Introduce advanced precision electrical discharge machines with high-resolution control systems and precise discharge power supplies, which can achieve control of the tiny discharge gap and ensure processing accuracy.

Equipped with a variety of electrode materials and tools to adapt to the processing of molds of different shapes and materials.

Advanced Injection Molding Machine

Have injection molding machines of different specifications for mold testing and small batch production to detect and solve problems in a timely manner during the mold manufacturing process.

The injection molding machine has precise temperature control, pressure control and injection speed control functions, which can simulate actual production conditions and verify the performance of the mold and product quality.

VI. Application Fields

Our custom molds are widely used in the following numerous fields:

Auto Parts

Manufacture high-precision molds for automotive interior parts, engine components, bumpers, etc., to meet the strict requirements of the automotive industry for product quality and performance.

Provide innovative mold solutions for the lightweight design of automobiles to reduce vehicle weight and improve fuel efficiency.

Electronic Equipment

Produce precision molds for mobile phone cases, computer accessories, electronic connectors, etc., to adapt to the rapid update requirements of the electronic industry.

Ensure that the molds can meet the requirements of the electronic equipment for high precision, small size and complex structure.

Medical Devices

Customize molds for plastic and rubber components in medical devices, such as syringes, infusion sets, surgical instruments, etc., in line with strict medical industry standards.

Pay attention to the hygiene and safety design of the molds to provide reliable mold support for the medical industry.

Consumer Goods

Provide beautiful and practical mold design and manufacturing services for various consumer goods, such as cosmetic packaging, household items, toys, etc.

Help you stand out in the consumer goods market and meet consumers’ pursuit of product appearance and quality.

Choose our custom precision plastic, rubber and silicone mold service, and you will get a professional, high-quality and efficient partner. Let’s join hands to create brilliance and create the perfect mold solution for your products!