In the aerospace industry, where safety and performance are of paramount importance, the role of CNC machining in manufacturing aerospace parts is nothing short of revolutionary.

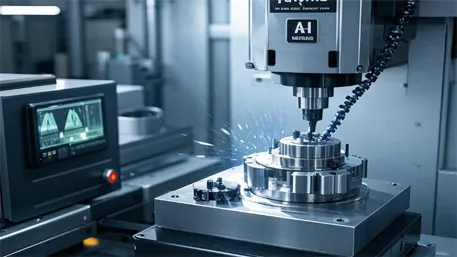

CNC machining, or Computer Numerical Control machining, is a highly advanced manufacturing process that involves the use of computer programs to control machine tools with exceptional precision. When it comes to aerospace parts, this level of accuracy is not just a luxury but a necessity.

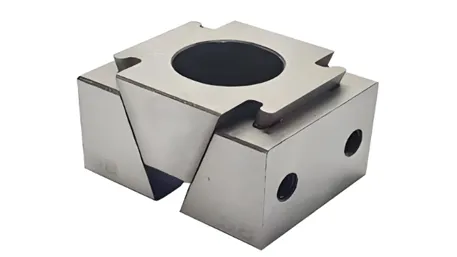

One of the primary reasons CNC machining is indispensable in aerospace is the strict requirements for lightweight yet incredibly strong components. For instance, in modern aircraft, titanium alloys are commonly used for critical parts. Titanium offers a high strength-to-weight ratio, but machining it requires precise control. Tolerances in aerospace parts often need to be within ±0.005 inches or even tighter to ensure optimal performance.

The precision offered by CNC machining ensures that every aerospace part fits perfectly within the overall assembly. This is crucial for minimizing air resistance, reducing vibration, and maintaining the structural integrity of the aircraft. Even the slightest deviation in part dimensions could have significant implications for the aircraft’s performance and safety. Take the example of turbine blades; their shape and dimensions must be exact to within microns to ensure efficient power generation and minimal stress on the engine.

From engine components like turbine blades and fuel injectors to structural parts like wing spars and fuselage frames, CNC machining is employed throughout the aerospace manufacturing process. The ability to produce parts with extremely tight tolerances helps improve the reliability and longevity of aerospace systems.

Another significant advantage of CNC machining in aerospace is its flexibility in prototyping and small batch production. This is essential during the design and development stages of new aircraft models, where frequent design iterations and modifications are common. CNC machines can quickly produce custom parts, allowing engineers to test and validate new concepts with speed and efficiency.

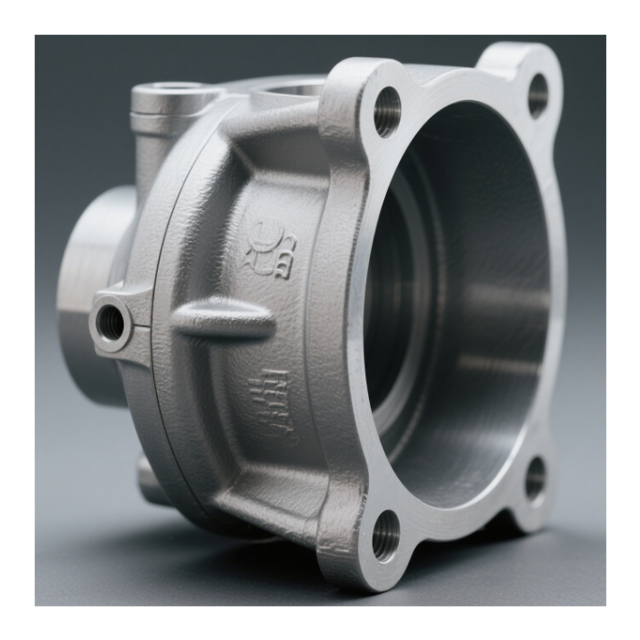

In the realm of multi-axis CNC machining, machines with five or more axes of movement provide enhanced capabilities for creating complex geometries. This is particularly useful for manufacturing parts like aerospace engine casings and impellers.

In addition to traditional metals, advanced materials such as carbon fiber-reinforced polymers (CFRP) and ceramic matrix composites (CMC) are also processed using CNC machining techniques. These materials offer superior properties but often pose challenges in terms of machining. However, with continuous advancements in CNC technology and tooling, these challenges are being overcome. For example, special diamond-coated cutting tools are used for machining CFRP to achieve a smooth surface finish and prevent delamination.

The aerospace industry is also demanding in terms of surface finish and quality control. CNC machining can provide smooth and flawless surfaces, reducing the need for extensive post-processing. Moreover, strict quality inspection processes are integrated into the CNC machining workflow. Non-destructive testing methods like ultrasonic inspection and X-ray tomography are employed to detect any internal flaws or defects in the parts.

Despite the high initial investment in CNC machinery and skilled operators, the long-term benefits in terms of quality, performance, and cost-effectiveness make it a worthwhile investment for aerospace manufacturers. The technology continues to evolve, with improvements in speed, accuracy, and multi-axis capabilities, enabling the production of ever more complex and sophisticated aerospace parts.

In conclusion, CNC machining plays a vital role in shaping the future of aerospace. It empowers the industry to reach new heights of performance, safety, and innovation, ensuring that our flights are not only efficient but also reliable and secure. For those unfamiliar with the aerospace sector, understanding the significance of CNC machining provides a glimpse into the complex and fascinating world of modern aviation engineering.