In the world of modern manufacturing, the ability to produce complex parts with exceptional accuracy and efficiency is crucial. This is where CNC (Computer Numerical Control) machining steps in, offering a revolutionary approach to shaping and fabricating intricate components that power various industries.

CNC machining is a sophisticated manufacturing process that utilizes computer-controlled machines to transform raw materials into highly detailed and complex parts. But what exactly makes a part “complex,” and how does CNC machining handle these challenges?

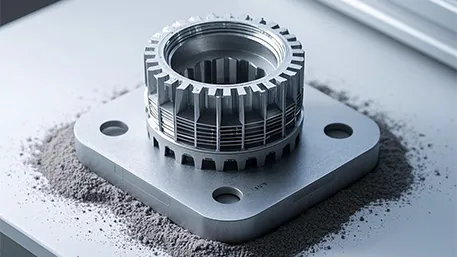

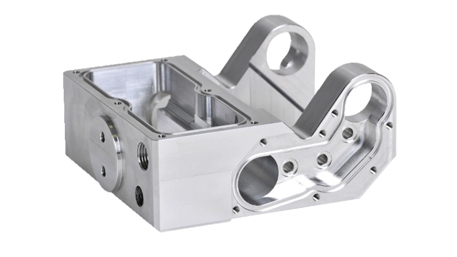

Complex parts often feature elaborate geometries, tight tolerances, and multiple interrelated features. They might have curves, holes, undercuts, and complex surface textures that are difficult to achieve through traditional manufacturing methods. For example, a medical implant with precise contours to fit the human anatomy or a high-performance automotive engine component with intricate cooling channels are considered complex parts.

One of the key strengths of CNC machining in handling such complexity is its precision. CNC machines are capable of moving the cutting tools with sub-millimeter accuracy, ensuring that every detail of the part is replicated precisely as designed. Tolerances as tight as a few micrometers can be achieved, guaranteeing a perfect fit and optimal performance of the final component.

The materials used for complex parts can vary widely, from common metals like steel and aluminum to exotic alloys, ceramics, and composites. CNC machining is adaptable to work with all these materials, tailoring the cutting parameters and tooling to suit the specific material properties. This flexibility allows manufacturers to choose the most suitable material for the part’s functionality and application.

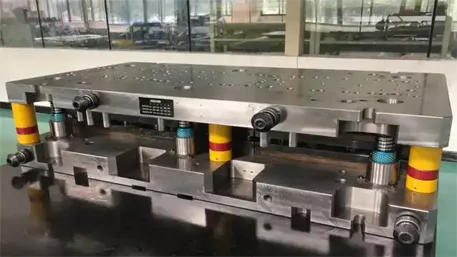

Another advantage of CNC machining complex parts is its ability to handle multiple operations in a single setup. Instead of moving the part between different machines for various processes like drilling, milling, and turning, a multi-axis CNC machine can perform all these operations sequentially without the need for repositioning. This not only saves time but also reduces the potential for errors due to multiple setups.

Complex parts often require complex toolpaths for machining. Advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software is used to generate these toolpaths, which guide the movement of the cutting tools. The software takes into account the part’s geometry, material, and machining requirements to optimize the toolpath for maximum efficiency and accuracy.

In addition to the manufacturing process itself, quality control plays a vital role in ensuring the success of CNC machining complex parts. Metrology tools such as coordinate measuring machines (CMM) and optical scanners are employed to inspect the finished parts and compare them against the design specifications. Any deviations can be identified and corrected before the parts are put into use.

CNC machining of complex parts is not limited to a specific industry. It is widely used in aerospace, medical, automotive, electronics, and many other fields where high-performance and precisely engineered components are essential. For instance, in the aerospace sector, complex turbine blades and engine components are machined using CNC technology to meet the strict requirements of flight.

The cost of CNC machining complex parts can initially seem high, especially when considering the investment in machinery, tooling, and skilled programming. However, when factoring in the reduced scrap, improved part quality, and the ability to produce parts that were previously impossible or extremely challenging to manufacture, the overall value becomes evident.

In conclusion, CNC machining of complex parts is a game-changer in modern manufacturing. It enables the creation of components that were once thought of as impossible to produce, pushing the boundaries of innovation and precision. For those unfamiliar with the manufacturing world, understanding the capabilities of CNC machining offers a fascinating insight into how technology is shaping the products we rely on every day.