Author: Xu Gong

CNC Milling Expert | 18 years experience | Led 300+ medical/aerospace projects

1. What is Custom CNC Milling? Precision Redefined

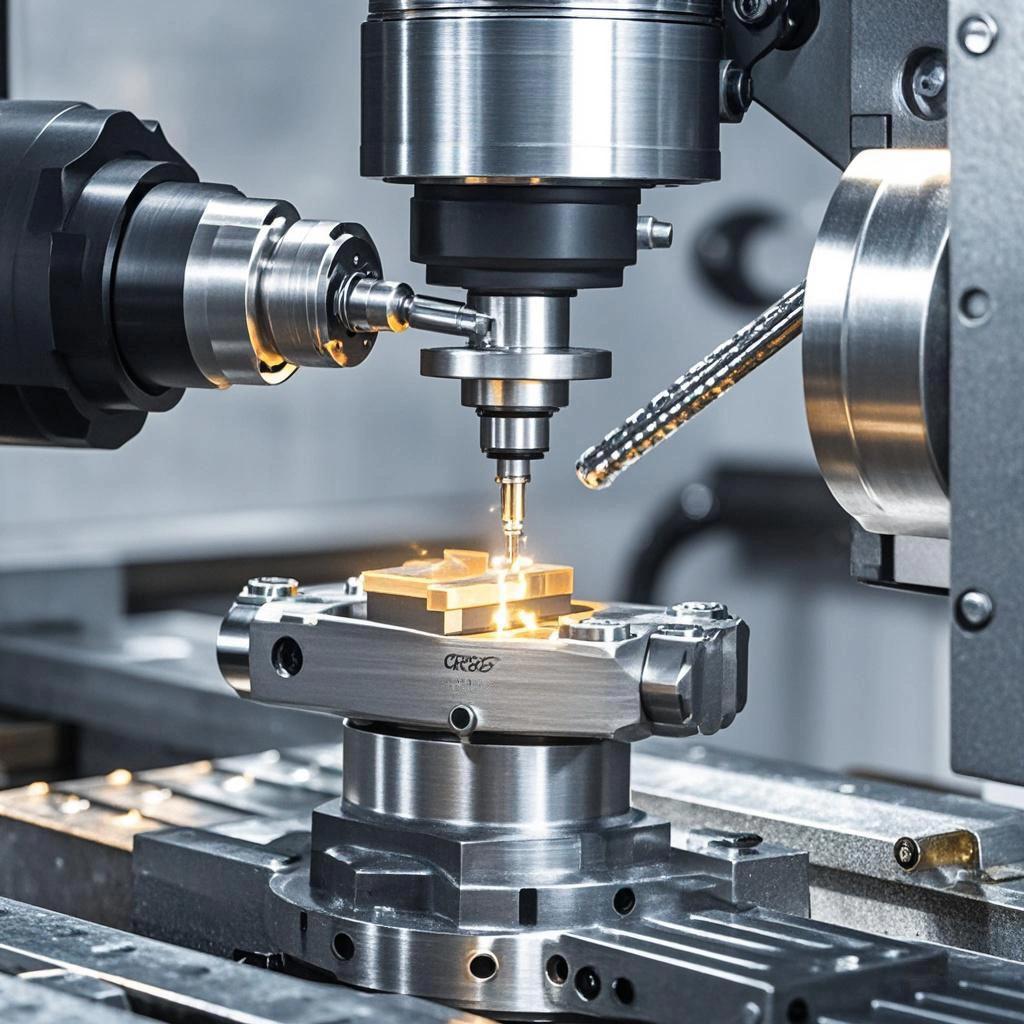

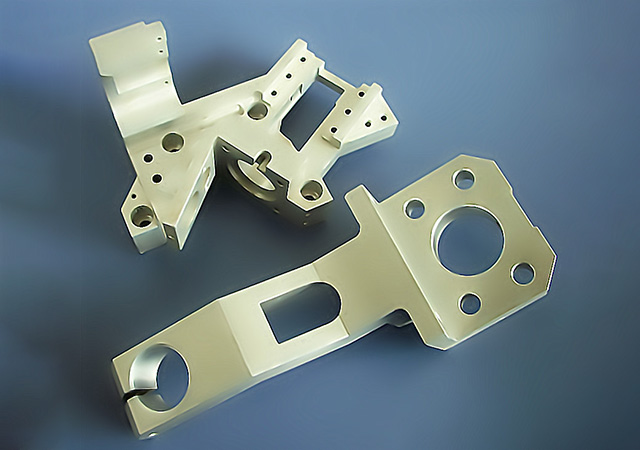

Custom CNC milling is a subtractive manufacturing process that uses computer-controlled machines to create complex, precise parts from various materials. Unlike traditional machining, CNC milling offers unmatched accuracy, repeatability, and flexibility, making it ideal for producing everything from simple brackets to intricate aerospace components.

Core Advantages

- Precision: ±0.005mm tolerance capability

- Complexity: Handles intricate geometries and 3D contours

- Repeatability: Consistent quality across production runs

- Material Versatility: Processes metals, plastics, composites

- Efficiency: Reduced lead times and production costs

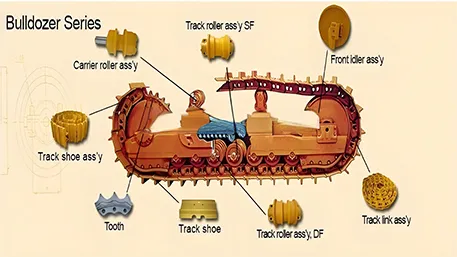

Industry Applications

Automotive

Medical

Electronics

Robotics

Defense

2. CNC Milling Process: From Design to Delivery

Step-by-Step Process Flow

- Design & Engineering: CAD modeling, DFM analysis, material selection

- Programming: CAM programming, toolpath optimization, simulation

- Machine Setup: Fixture design, tool selection, workholding

- Machining: Roughing, semi-finishing, finishing operations

- Quality Control: CMM inspection, surface finish testing, dimensional verification

- Finishing & Delivery: Surface treatment, packaging, shipping

Key Process Parameters

| Parameter | Aluminum Alloy | Stainless Steel | Titanium Alloy |

|---|---|---|---|

| Cutting Speed (m/min) | 300-500 | 80-120 | 50-100 |

| Feed Rate (mm/min) | 1000-3000 | 300-800 | 200-500 |

| Depth of Cut (mm) | 2-5 | 1-3 | 0.5-2 |

| Surface Finish (Ra μm) | 0.4-1.6 | 0.8-3.2 | 0.8-3.2 |

Note: Data is for reference only. Actual parameters may vary based on specific material grades and machine capabilities.

3. Materials & Machining Capabilities

Material Expertise

Aluminum

6061, 7075, 2024

Steel

Stainless, Alloy, Tool

Titanium

Ti-6Al-4V, CP Ti

Plastics

ABS, PEEK, POM

Machining Capabilities

3-Axis Milling

For simple to moderately complex parts requiring flat surfaces, holes, and basic contours.

- Accuracy: ±0.01mm

- Max workpiece: 1000×800×600mm

- Spindle speed: up to 15,000rpm

5-Axis Milling

For complex 3D geometries, undercuts, and multi-sided parts that require simultaneous axis movement.

- Accuracy: ±0.005mm

- Max workpiece: 800×600×500mm

- Spindle speed: up to 24,000rpm

4. Customization Services: Tailored Solutions

Our Customization Capabilities

- Design Optimization: DFM analysis, topology optimization, weight reduction

- Material Customization: Special alloys, composites, surface treatments

- Process Development: Specialized tooling, fixturing, machining strategies

- Tolerance Control: Tight tolerance machining (±0.002mm)

- Surface Finishing: Anodizing, plating, painting, polishing

- Assembly Services: Subassembly, testing, certification

Customization Process

Requirements Analysis

Understanding your design intent, performance requirements, and production needs

Design Proposal

Providing 2-3 design concepts with technical specifications and cost estimates

Prototype Development

Creating prototypes for testing, validation, and design refinement

Production

Scaling up to full production with consistent quality control

5. 2026 CNC Milling Trends & Future Developments

Key Trends Shaping the Industry

AI-Native Machining

AI-driven systems that automatically adjust cutting parameters based on real-time sensor data.

- Adaptive toolpath optimization

- Predictive maintenance scheduling

- Quality anomaly detection

Digital Twin Technology

Virtual replicas of machining processes for simulation, optimization, and training.

- Virtual commissioning

- Process validation

- Remote monitoring

Sustainability & Efficiency

Green Manufacturing

Eco-friendly practices reducing energy consumption and material waste.

- Energy-efficient machines (25% reduction)

- Dry machining technologies

- Recycled material utilization

Hybrid Manufacturing

Combining additive and subtractive processes for complex part production.

- 3D printing + CNC finishing

- In-situ quality inspection

- Reduced lead times

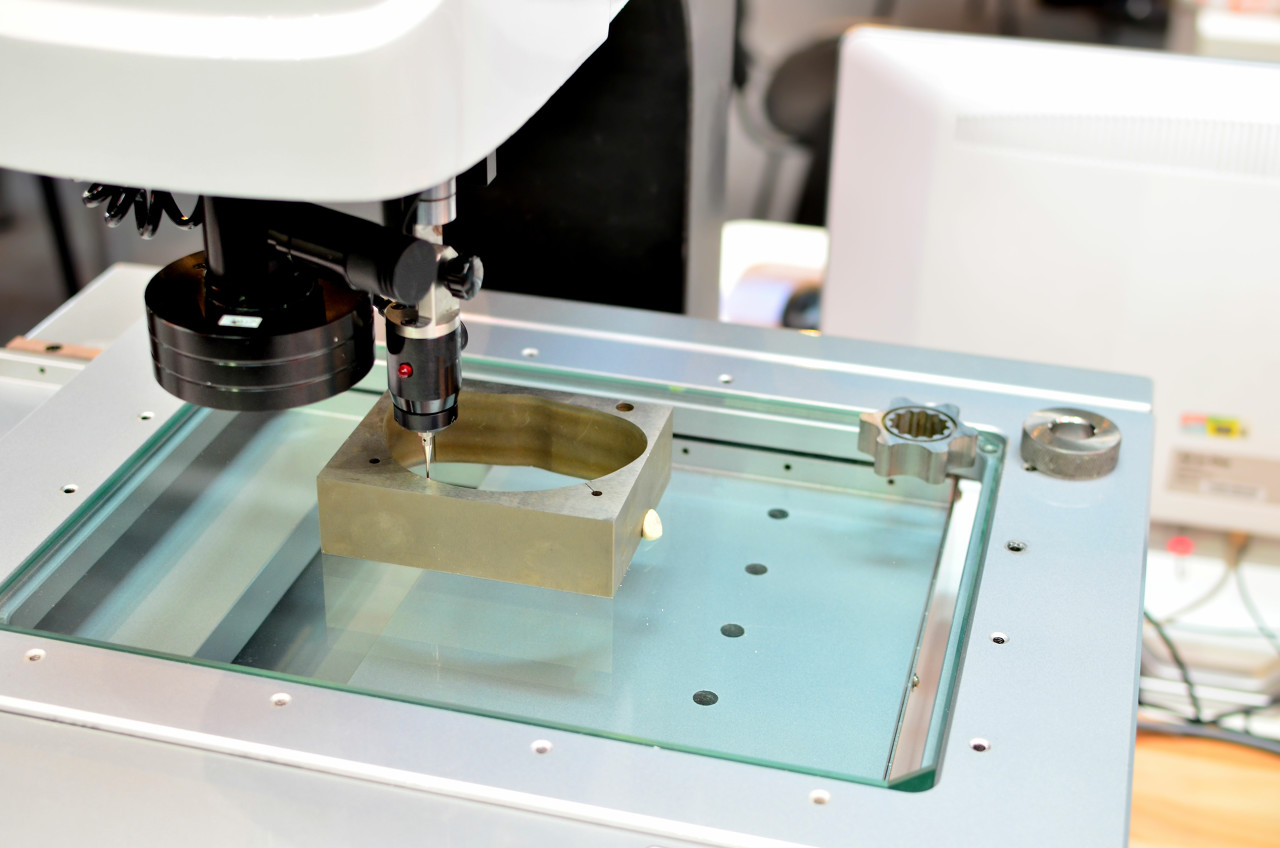

6. Quality Control & Testing Procedures

Comprehensive Testing Methods

CMM Inspection

Coordinate measuring machine for dimensional accuracy verification

Surface Roughness

Ra/Rz measurement for surface finish quality

Material Testing

Hardness, tensile strength, chemical composition analysis

Functional Testing

Assembly fit, operational performance validation

Quality Assurance Statistics

| Metric | Our Performance | Industry Average | Improvement |

|---|---|---|---|

| First Pass Yield | 98.5% | 92.3% | +6.2% |

| On-Time Delivery | 99.2% | 94.7% | +4.5% |

| Customer Satisfaction | 97.8% | 91.5% | +6.3% |

Note: Data based on 2025 production metrics. Actual results may vary based on project complexity and requirements.

7. Success Stories & Case Studies

Aerospace Component Project

Challenge: Manufacturing complex titanium alloy components for jet engine applications with tight tolerances and high surface finish requirements.

Solution: Implemented 5-axis simultaneous machining with advanced toolpath strategies and in-process inspection.

Results: Achieved ±0.003mm tolerance, Ra 0.4μm surface finish, and reduced production time by 40% compared to traditional methods.

Medical Device Components

Challenge: Producing surgical instrument components with biocompatible materials and strict cleanliness requirements.

Solution: Used dedicated medical-grade machining cells with traceable materials and cleanroom processes.

Results: Zero defects in 10,000+ parts produced, ISO 13485 certification achieved, and customer became a long-term partner.

8. Frequently Asked Questions

Technical Questions

Q: What is the minimum tolerance you can achieve?

A: Our standard tolerance is ±0.01mm, but we can achieve ±0.002mm for critical applications using specialized processes and equipment.

Q: How do you handle material deformation?

A: We use stress-relieved materials, optimized cutting strategies, and in-process cooling to minimize deformation. For critical parts, we implement multiple machining stages with intermediate stress relief.

Q: What surface finishes do you offer?

A: We offer Ra 0.4μm to Ra 6.3μm as standard, with special processes available for mirror finishes (Ra 0.02μm) and textured surfaces.

Business Questions

Q: What is your minimum order quantity?

A: We have no minimum order quantity. We support everything from single prototypes to high-volume production runs.

Q: How long is your typical lead time?

A: Prototypes: 3-5 days, small batches: 7-10 days, production runs: 2-4 weeks depending on volume.

Q: Do you offer design services?

A: Yes, we provide DFM analysis, design optimization, and full CAD modeling services to help you get the most out of your CNC machining project.

9. Get Started with Your Custom Project

How to Begin

- Submit Your Design: Send us your CAD files, drawings, or concept sketches

- Get a Free Quote: We’ll provide a detailed quote within 24 hours

- Design Review: Our engineers will review your design and suggest optimizations

- Prototype Development: We’ll create prototypes for testing and validation

- Production: Once approved, we’ll scale up to full production

Contact Information

Email:

charlie@plasticmetalparts.com

Phone:

+86-18150097490