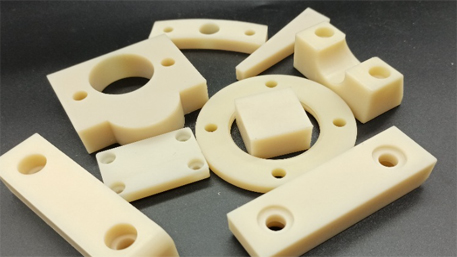

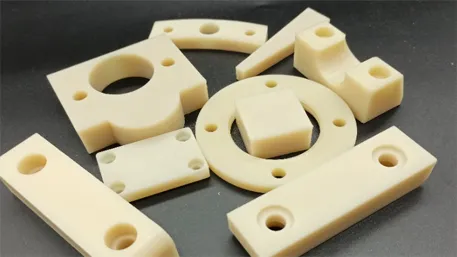

As industrial manufacturing shifts toward high-strength, wear-resistant, and lightweight solutions, nylon (polyamide, PA) stands out as the premier material for customized engineering plastic parts due to its exceptional comprehensive properties. This article systematically explores the core advantages of custom nylon plastic parts, covering material characteristics, processing technologies, application scenarios, and quality control, to provide professional customization solutions for high-end manufacturing.

Nylon (PA) achieves a perfect balance of high strength, fatigue resistance, and chemical resistance through molecular structure design and modification technologies. Its core properties and application advantages are as follows:

| Property |

Typical Parameters (PA66-GF30) |

Core Advantages |

Application Value |

| Tensile Strength |

180 MPa |

Excellent load-bearing capacity for high-stress scenarios |

Load-bearing components: gears, bearings, structural connectors |

| Flexural Strength |

240 MPa |

Strong anti-deformation for long-term loads |

Automotive suspension parts, industrial mechanical drives |

| Heat Deflection Temp. |

250℃ (1.82MPa) |

High-temperature resistance for harsh environments |

Engine components, high-temperature industrial parts |

| Coefficient of Friction |

0.3 (unlubricated) |

Self-lubricating to reduce friction loss |

Precision gears, pulleys, and other moving parts |

| Water Absorption |

1.5% (equilibrium) |

Modified to ≤0.5% for moisture resistance |

Outdoor equipment, bathroom hardware |

- Glass Fiber Reinforcement (GF-PA): Adding 30% glass fiber increases strength by 50% and reduces thermal expansion to 2.5×10⁻⁵/℃, ideal for high-precision assembly.

- Flame Retardant Modification: Halogen-free flame retardants achieve UL94 V-0 rating (1.6mm thickness), meeting fire safety requirements for electronics.

- Wear Resistance Modification: Molybdenum disulfide (MoS₂) filler reduces wear by 40%, doubling the lifespan of moving parts.

- Chemical Resistance: Resistant to motor oil and gear oil, stable between -40℃ and 150℃, suitable for harsh automotive and aerospace environments.

- Food-Grade Certification: FDA 21 CFR 177.1500-compliant nylon 6 (PA6) for food-contact applications like catering equipment.

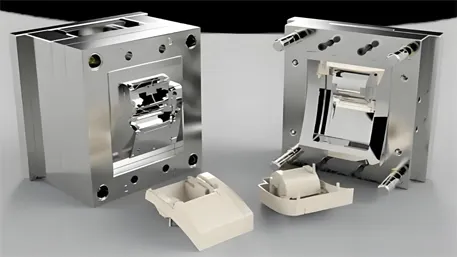

- Mold Flow Analysis Optimization:

Moldflow simulation controls glass fiber orientation consistency, stabilizing shrinkage rate within ±0.2% and dimensional tolerance for complex structures at ±0.03mm.

- Mold Precision Control:

NAK80 mirror-finish tool steel (HRC40 hardness) with EDM machining achieves cavity surface roughness Ra≤0.2μm, enabling precise forming of 0.5mm thin walls and 1:10 deep holes.

- Intelligent Temperature Control:

Barrel temperature controlled within ±1℃, conformal cooling channels reduce cycle time by 25%, increasing daily capacity to 8,000 pieces (2-cavity mold).

- Wear-Resistant Coating:

CVD-deposited tungsten carbide coating increases surface hardness to HV1200 and reduces friction to 0.15 for high-speed moving parts.

- Conductive Modification:

Carbon nanotube (CNT)-filled antistatic nylon achieves surface resistance ≤10⁶Ω, meeting ESD protection for electronic component packaging.

- Laser Marking:

1064nm fiber laser marking ensures 300dpi clarity, resistant to 50 alcohol wipes, enabling part traceability and anti-counterfeiting.

- Application Analysis: Clarify load type (static/dynamic), operating temperature (peak/steady state), contact media (oils/acids), and precision level (IT6 tolerance or functional tolerance).

- Solution Design: Provide material selection (PA6/PA66/PA12), modification plans (glass fiber content/flame retardancy), and process routes (injection molding/CNC/3D printing) within 2 business days.

- Structural Optimization:

ANSYS finite element analysis optimizes gear parameters (20° pressure angle, 2.5 module), reducing tooth root stress by 15% and predicting 30% longer life.

- Rapid Prototyping:

- SLS 3D Printing: 3-day delivery of nylon 12 prototypes (98% density) for high/low-temperature testing;

- Aluminum Mold Small Batch (100-piece minimum): Replicates final precision for assembly stress testing.

- Process Control:

Hourly parameter monitoring (pressure/temperature/injection speed) via SPC ensures critical dimension CPK≥1.67 and defect rate ≤0.05%.

- Inspection System:

| Inspection Item |

Standard Requirements |

Equipment/Method |

Pass Criteria |

| Dimensional Accuracy |

Critical dimensions ±0.02mm |

Coordinate Measuring Machine (CMM) |

100% full-size pass rate |

| Fatigue Life |

10⁶ cycles without fracture |

Fatigue testing machine |

100% compliance |

| Temperature Resistance |

No deformation at 150℃ for 24h |

Thermal chamber |

Dimensional change ≤0.3% |

- Engine Components:

PA66-GF30 injection-molded intake manifolds resist 180℃ and fuel corrosion, reducing weight by 40% compared to aluminum, ideal for EV lightweight design.

- Chassis Systems:

Nylon 12 brake tube connectors withstand 25MPa burst pressure and -40℃ brittleness resistance, compliant with ISO 7628 automotive standards.

- Transmission Parts:

Helical gears (3 module, 24 teeth) in gearboxes feature oil-lubricated design, ≤65dB noise, and 5,000+ hour life, cutting costs by 60% versus copper gears.

- Sealing Components:

Modified nylon 6 O-rings exhibit ≤10% compression set and no leakage at 10MPa, suitable for high-pressure hydraulic systems.

- Connectors:

High-temperature nylon (PA46) connectors withstand 260℃ soldering, with contact resistance ≤50mΩ for high-density PCB connections.

- Aerospace Parts:

Carbon fiber-reinforced nylon (CF-PA) UAV structures offer 200MPa tensile strength and 1.3g/cm³ density, 50% lighter than aluminum, meeting aerospace lightweight needs.

- Medical Devices:

Biocompatible nylon (PA12) surgical handles comply with ISO 10993, featuring Ra≤0.4μm surface roughness for easy sterilization.

- Sports Equipment:

Wear-resistant nylon (PA6-GF20) ski bindings pass EN 1399 certification with ≥80kJ/m² impact resistance at -30℃.

- Bio-Based Nylon: PA1010 from castor oil with 70% bio-content reduces carbon emissions by 40%, suitable for eco-friendly designs.

- Nanocomposite Nylon: Graphene-reinforced PA6 triples thermal conductivity, solving overheating in 5G equipment heat dissipation parts.

- Micro-Injection Molding: Forms parts <0.1g with ±0.005mm tolerance, meeting precision assembly for MEMS sensors.

- Multi-Material Co-Injection: Inner PA66 load-bearing + outer TPU anti-slip composite molding for tool handles, increasing grip by 20% with excellent weather resistance.

- Digital Twin Design: AI-driven mold flow analysis improves fiber orientation prediction to 95%, reducing trial molds by 60% and shortening mold development to 15 days.

- Intelligent Quality Inspection: Machine vision system detects defects ≥0.05mm at 500 pieces/minute, with miss rate <0.01%.

Q1: What is the maximum temperature resistance of nylon parts?

A: Unmodified nylon (PA6) operates ≤120℃ long-term; GF-PA66 withstands 150℃; specialty nylon (PA46) resists short-term 260℃. Choose modifications based on your application.

Q2: How to prevent dimensional changes due to nylon hygroscopy?

A: Use moisture-proof packaging (dew point ≤-40℃), dry raw materials at 120℃ for 4 hours, and control finished product moisture ≤0.3% for 90% better dimensional stability.

Q3: What’s the minimum order quantity for small batches?

A: 100 pieces minimum, using quick aluminum molds (7-day development), with unit costs 20% higher than steel molds—ideal for samples and R&D prototyping.

Q4: What certifications are needed for food-grade nylon parts?

A: Require FDA, EU 10/2011, and China GB 4806.6 certifications, ensuring extractable migration ≤0.1mg/kg for catering equipment and baby products.

“Collaborating with the team for 20,000 automotive nylon gears, we achieved delivery in just 40 days. Parts passed 10⁶ fatigue cycles without fracture, met ±0.02mm precision, and reduced weight by 60% versus metal gears. Fiber orientation optimization lowered noise by 10dB, perfectly meeting the silent requirements of new energy vehicles. Their professional material selection and process control delivered a transformative solution for our drivetrain project!” ——A New Energy Vehicle Parts Supplier

Whether for high-load mechanical drives or high-temperature engine components, we leverage material science and intelligent processes to deliver end-to-end solutions. Contact us for a tailored proposal and unlock the full potential of nylon parts—where high strength meets high precision.