Custom Aluminium Gravity Casting Die Casting Housing Parts

Surface Treatment

Anodizing: Film thickness is 5 – 25μm (hard anodizing ≥ 25μm), heat – resistant up to 1500℃, and coloring is supported (such as champagne color, black, etc.).

Electrophoresis / Spraying: Salt – spray resistance is > 1000 hours (for electrophoresis), coating thickness is 60 – 100μm (for powder spraying), and it has UV resistance.

Sandblasting Treatment: Roughness is Ra 1.6 – 6.3μm, which enhances the coating adhesion.

Anodizing: Film thickness is 5 – 25μm (hard anodizing ≥ 25μm), heat – resistant up to 1500℃, and coloring is supported (such as champagne color, black, etc.).

Electrophoresis / Spraying: Salt – spray resistance is > 1000 hours (for electrophoresis), coating thickness is 60 – 100μm (for powder spraying), and it has UV resistance.

Sandblasting Treatment: Roughness is Ra 1.6 – 6.3μm, which enhances the coating adhesion.

Mechanical Properties

Tensile Strength: 200 – 290MPa (under different processes / treatment conditions)

Elongation: 2% – 12% (from ADC12 to 6061 – T651)

Hardness: HB 70 – 95, and heat treatment strengthening of T6/T651 is supported.

Tensile Strength: 200 – 290MPa (under different processes / treatment conditions)

Elongation: 2% – 12% (from ADC12 to 6061 – T651)

Hardness: HB 70 – 95, and heat treatment strengthening of T6/T651 is supported.

Production Capacity

Mold Life: Die – casting mold has 500,000 – 1,000,000 shots, and gravity casting mold has 100,000 – 300,000 shots.

Delivery Cycle: Prototype mold takes 7 – 15 days, small – batch production (starting from 100 pieces) takes 7 – 15 days, and 72 – hour rush service is available.

Quality Certification: ISO 9001. The yield rate is ≥ 98% (for die – casting) / ≥ 96% (for gravity casting), and a full – process inspection report is provided.

Mold Life: Die – casting mold has 500,000 – 1,000,000 shots, and gravity casting mold has 100,000 – 300,000 shots.

Delivery Cycle: Prototype mold takes 7 – 15 days, small – batch production (starting from 100 pieces) takes 7 – 15 days, and 72 – hour rush service is available.

Quality Certification: ISO 9001. The yield rate is ≥ 98% (for die – casting) / ≥ 96% (for gravity casting), and a full – process inspection report is provided.

Categories: Die casting, Stamping

Tag: Die Casting

Description

Specification for Custom Aluminum Gravity Casting and Die Casting Shell Parts

I. Core Process Characteristics

1. Gravity Casting Process

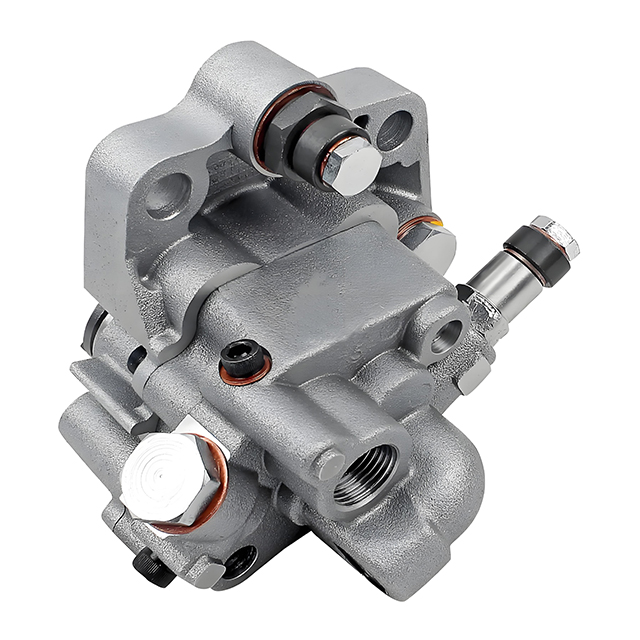

- Principle: Molten aluminum fills the mold cavity under gravity, ideal for complex internal structures (e.g., gasoline nozzle housings).

- Dimensional Accuracy: Tolerance grade CT8-10 (GB/T 6414); for 10-16mm dimensions, tolerance is ±0.38mm, suitable for medium-precision structural parts.

- Surface Roughness: Ra value 6.3-12.5μm; post-machining or surface treatment is recommended for improved finish.

- Applications: Large housings, thick-walled parts, complex internal cavities (e.g., engine blocks, fuel tanks).

2. Die Casting Process

- Principle: Aluminum is injected into the mold at high pressure and speed (10-50m/s), suitable for complex external shapes with simple interiors (e.g., gearboxes, electronic enclosures).

- Dimensional Accuracy: Tolerance grade CT6-8; for 10-16mm dimensions, tolerance is ±0.28mm (±0.1mm achievable with high-precision molds).

- Surface Roughness: Ra value 4-8μm (Ra 1.6μm achievable with advanced processes), meeting direct aesthetic requirements.

- Applications: Thin-walled parts (minimum wall thickness 0.5mm), high-volume production, complex exteriors (e.g., automotive radiators, 5G base station enclosures).

II. Material Systems

1. Aluminum Alloy Grades & Properties

- A356

- Composition: Si 6.5-7.5%, Mg 0.2-0.4%, Fe≤0.7%.

- Properties: Tensile strength 200-300MPa (T6 treatment), elongation 12%, ideal for high-strength, corrosion-resistant applications (e.g., automotive wheels, pump bodies).

- ADC12

- Composition: Si 9.6-12%, Cu 1.5-3.5%, Fe≤1.3%.

- Properties: Tensile strength 220MPa, hardness HB 80-90, excellent fluidity for complex die castings (e.g., motor end caps, home appliance casings).

- 6061

- Composition: Mg 0.8-1.2%, Si 0.4-0.8%, Cu 0.15-0.4%.

- Properties: Tensile strength 290MPa (T651 temper), yield strength 240MPa, excellent weldability for post-machined structural parts (e.g., industrial equipment brackets, aerospace components).

2. Material Certifications

- Compliant with GB/T 15115 (Die Cast Aluminum Alloys) and GB/T 1173 (Casting Aluminum Alloys); SGS and RoHS test reports available.

III. Surface Treatment Options

1. Anodizing

- Standard Anodizing: Film thickness 5-25μm, hardness ≥200HV, temperature resistance 1500℃, colorable (champagne, black, etc.), suitable for outdoor equipment enclosures.

- Hard Anodizing: Film thickness ≥25μm, hardness >350HV, low porosity, high dielectric strength, ideal for wear-resistant applications (e.g., automotive parts, industrial machinery casings).

- Electrolytic Coloring: Achieves tones like bronze and black via controlled particle deposition, with high color fastness.

2. Other Treatments

- Electrophoretic Coating: Coating thickness 15-30μm, salt spray resistance >1000 hours, suitable for high-corrosion environments (e.g., telecom enclosures).

- Powder Coating: Coating thickness 60-100μm, wide color options, excellent UV resistance for outdoor power equipment.

- Sandblasting: Ra value 1.6-6.3μm, removes burrs and enhances coating adhesion.

IV. Mechanical Properties

| Alloy Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Elongation (%) | Typical Applications |

|---|---|---|---|---|---|

| A356-T6 | 200-300 | 160-240 | 70-90 | 8-12 | Automotive wheels, pump bodies |

| ADC12 | 220 | 150 | 80-90 | 2-5 | Motor end caps, home appliance casings |

| 6061-T651 | 290 | 240 | 95 | 12 | Industrial brackets, aerospace components |

V. Production Capacity & Quality Control

1. Production Capabilities

- Mold Development: Die casting mold life 500,000-1,000,000 cycles; gravity casting mold life 10,000-30,000 cycles. Rapid prototyping (7-15 days for sample molds).

- Mass Production Lead Time: Small batches (100-500pcs): 7-15 days; medium batches (500-5,000pcs): 15-30 days. Rush orders supported.

- Minimum Order Quantity (MOQ): 50pcs for gravity casting; 100pcs for die casting. Small-batch customization available.

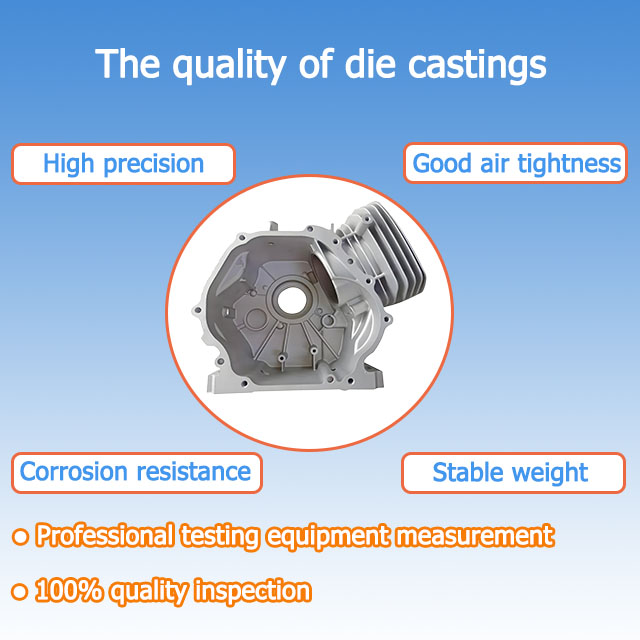

2. Quality Control

- Testing Equipment: Spectrometer (chemical composition accuracy ±0.01%), CMM (accuracy ±0.01mm), metallographic microscope (500x magnification).

- Quality System: ISO 9001:2015 certified, compliant with GB/T 15115-2015 and ASTM B85. Full-process traceability reports provided.

- Defect Rate: Die cast parts yield ≥98%; gravity cast parts yield ≥96%. DPPM (Defects Per Million) ≤500.

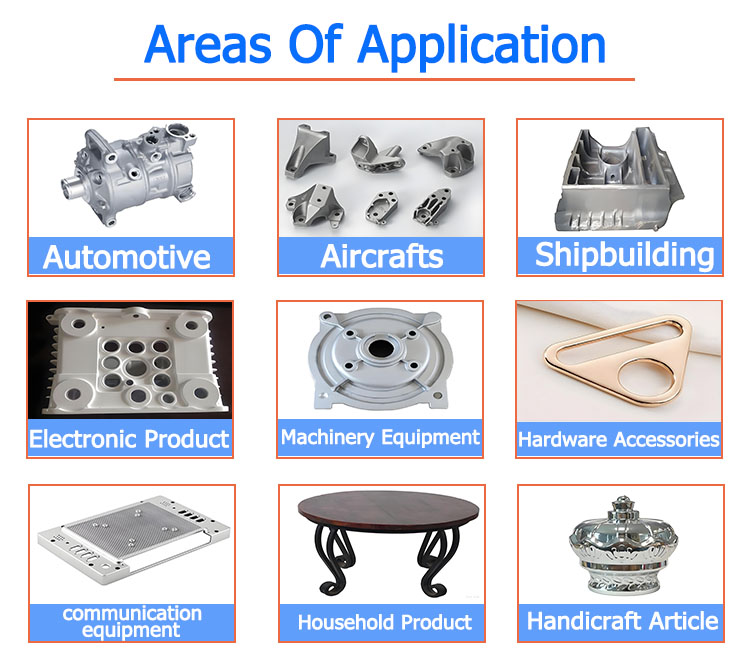

VI. Application Fields

- Automotive Industry: Engine blocks, transmission housings, new energy vehicle battery pack enclosures.

- Electronics & Telecommunications: 5G base station radiators, server enclosures, smart device structural parts.

- Industrial Equipment: Pump bodies, valve housings, robotic joint components.

- Consumer Electronics: Laptop casings, smart home controller enclosures.

- Aerospace: Lightweight structural parts, satellite components.

VII. Value-Added Services

- Design Support: DFM (Design for Manufacturability) optimization to reduce material costs by 30%.

- Secondary Processing: CNC machining (accuracy ±0.01mm), laser engraving, assembly testing.

- Packaging & Logistics: Custom anti-collision packaging; global sea/air freight (72-hour emergency delivery).

Customization Process: Requirement consultation → 3D modeling → Mold design → Sample approval → Mass production → Quality inspection → Delivery.

Contact Information:

[Company Name]

Address: [Detailed Address]

Tel: [Phone Number]

Email: [Email Address]

Website: [Company URL]

[Company Name]

Address: [Detailed Address]

Tel: [Phone Number]

Email: [Email Address]

Website: [Company URL]

(Note: The above parameters are typical values and can be customized according to customer requirements.)