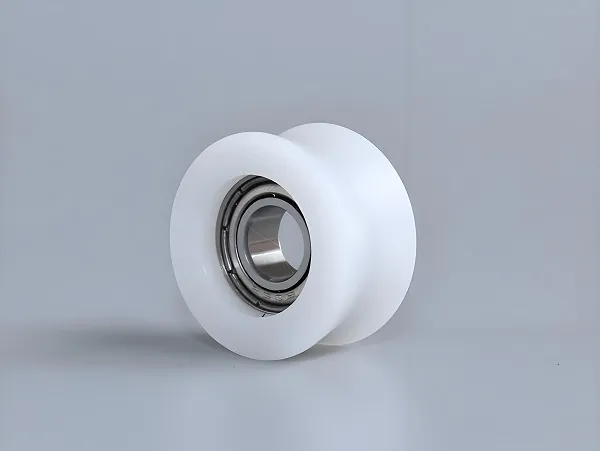

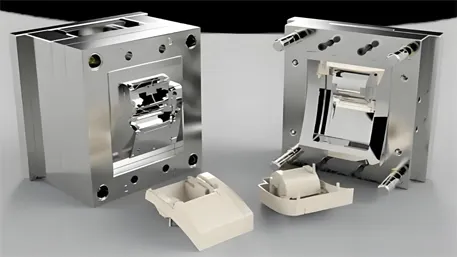

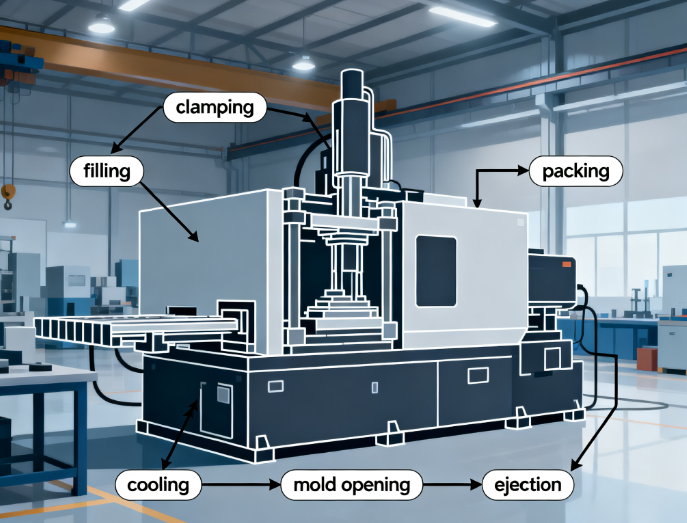

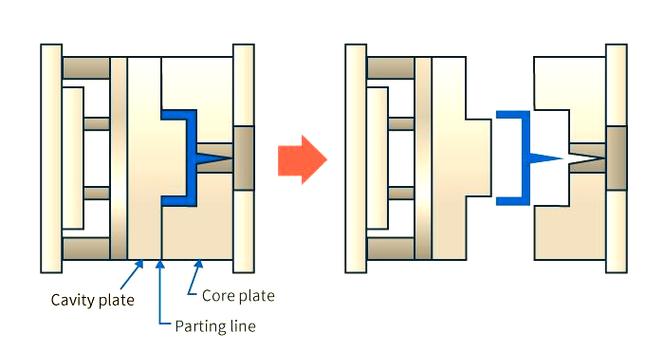

Answer: The injection molding process involves heating plastic raw materials to a molten state, applying pressure through the screw or plunger of an injection molding machine to inject the molten material into a closed mold cavity through a nozzle. After cooling and solidifying, the mold is opened to remove the molded product. This process includes steps such as plasticizing, injecting, cooling, and demolding.

Expansion: The injection molding process is applicable to thermoplastics and some thermosetting plastics. The quality of the mold directly affects the precision of the product and production efficiency. Its advantages lie in the ability to mass – produce products with complex shapes, featuring high precision, good surface quality, and high production efficiency. However, the design and manufacturing costs of the mold are high, and the cycle is long. It is suitable for the mass production of finalized products. This process is widely used in fields such as daily necessities, automotive parts, electronics and electrical appliances, and medical devices. With the development of technology, new techniques such as two – color injection molding and gas – assisted injection molding have emerged, expanding the application scenarios.