Answer

The lifespan of injection – molding molds varies greatly and there is no fixed value. Simple molds with low requirements may only be used for tens of thousands of times. In general production scenarios, the lifespan of common injection – molding molds is usually around 300,000 – 1,000,000 times. However, if the mold has excellent manufacturing processes, high – quality materials, and proper maintenance, and is used in production with not – too – high requirements, it is possible to reach 2,000,000 times or even more. For example, the precision injection – molding molds manufactured by some technologically leading enterprises can stably have a service life of more than 1,500,000 mold cycles. In the automotive industry, ordinary injection – molding molds may be used for 200,000 – 300,000 mold cycles, some in the electronics industry can reach 500,000 mold cycles, and some in the daily necessities industry can even be as high as 1,000,000 mold cycles.

Extended Answer

The lifespan of injection – molding molds is a crucial indicator affected by a variety of complex interacting factors. In – depth exploration of these factors is of great significance for improving mold lifespan and reducing production costs.

From the perspective of mold design, whether the structural design is reasonable plays a decisive role. Molds with sharp, thin, and brittle parts will bear extremely high stress at these parts during the injection – molding process, and stress concentration is likely to occur, leading to premature cracking and damage of the mold. For example, small cores and thin – walled ribs inside the mold, if the strength and demolding are not fully considered during the design, may break or deform in a relatively short time under the impact of frequent injection – molding pressure, seriously shortening the mold lifespan. On the contrary, a simple front – and – rear opening mold structure, under normal use and without human – caused damage, has a relatively uniform stress distribution and a smoother mold opening and closing process, theoretically having a longer service life. At the same time, a reasonable demolding design is also crucial. If the demolding draft angle is too small, there will be a large friction force between the product and the mold cavity during demolding, which may not only cause scratches on the product surface but also accelerate the wear of the mold, affecting the mold lifespan over time. A suitable demolding draft angle can enable the product to be demolded smoothly, reducing the friction and wear between the mold and the product.

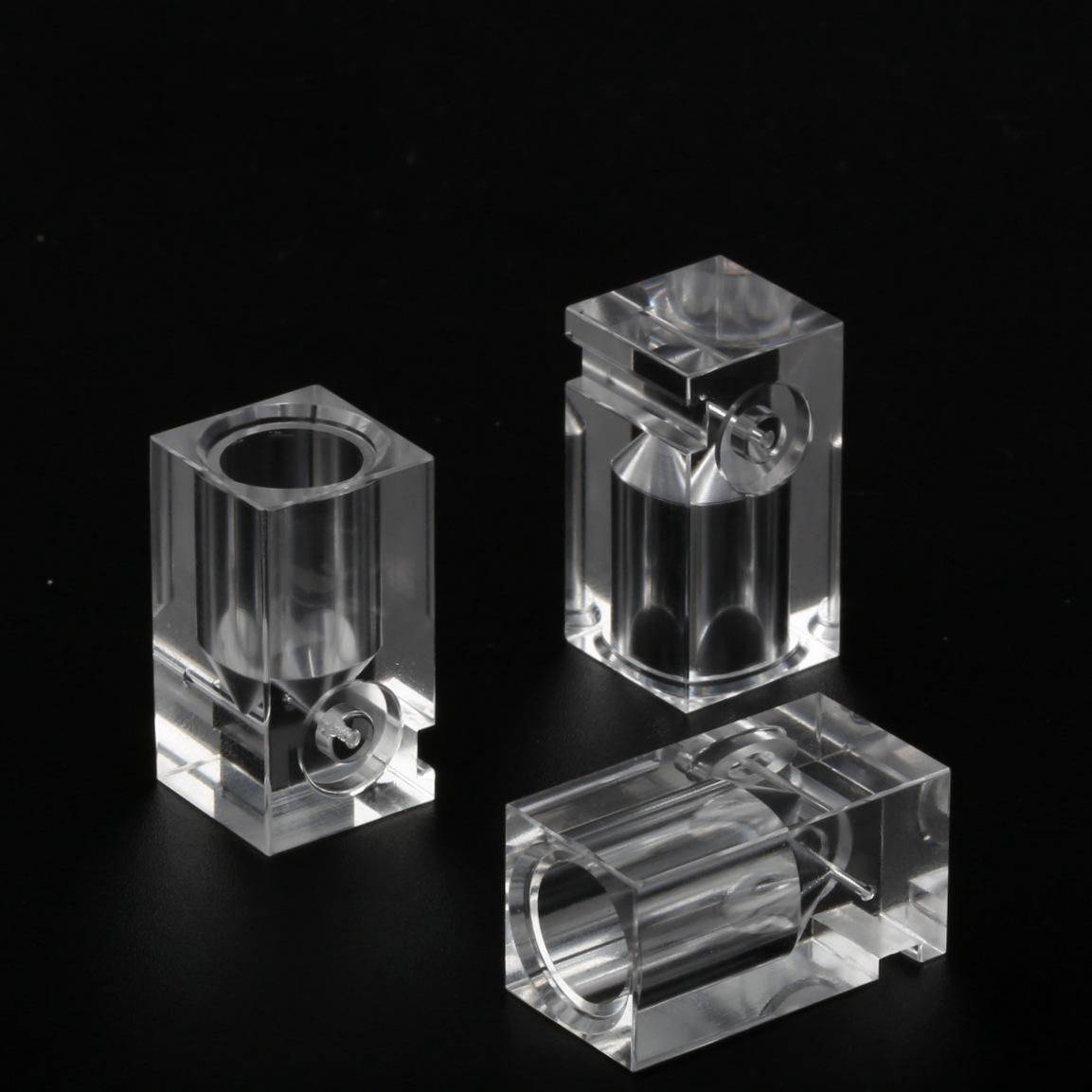

Material selection is another core factor affecting the lifespan of injection – molding molds. Mold steel is the main material for manufacturing injection – molding molds, and different types of mold steel vary significantly in performance and price. Ordinary carbon tool steel has a relatively low cost, but its hardness, wear resistance, and corrosion resistance are limited, and it is only suitable for occasions with low requirements for mold lifespan and small production batches. High – quality alloy mold steels such as Cr12MoV, NAK80, and S136 have high hardness, good wear resistance, and excellent corrosion resistance. For example, when producing injection – molding molds for optical lenses with extremely high requirements for surface quality, S136 steel with good mirror – processing performance is often selected. It can effectively resist the erosion and corrosion of the plastic melt during the injection – molding process, ensuring that the mold can still maintain a high – precision mirror surface after long – term use, thus ensuring the high – quality production of lenses and greatly improving the mold lifespan. In addition to the steel itself, the quality stability of the material cannot be ignored. Steel with internal defects (such as sand holes, cracks, etc.) will gradually expand these defects under the action of stress during the service of the mold, eventually leading to mold failure.

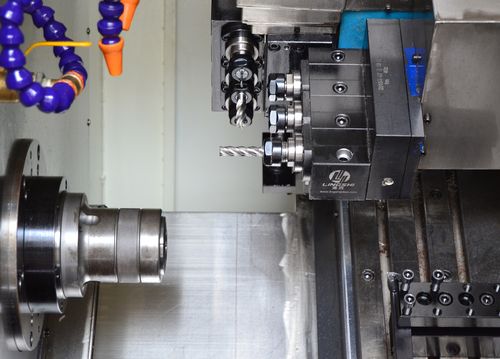

The manufacturing process level is directly related to the accuracy and surface quality of injection – molding molds, and thus affects the mold lifespan. Traditional ordinary milling has a low equipment cost, but limited processing accuracy and a large surface roughness, which is difficult to meet the requirements for high – precision molds. The use of computer – numerical – control (CNC) technology can achieve high – precision and automated production, accurately machining complex – shaped mold parts, effectively reducing processing errors, and improving the assembly accuracy and overall quality of the mold. For example, through CNC high – speed and high – precision machining, the machining accuracy of the mold cavity can reach ±0.001mm, which greatly improves the accuracy retention of the mold and extends the mold service life. Advanced electrical – discharge machining technology can machine complex shapes and tiny structures, but it will form a layer of modified layer on the mold surface. If the subsequent treatment is improper, this modified layer may become the origin of fatigue cracks on the mold surface, reducing the mold lifespan. Therefore, during the manufacturing process, appropriate process parameters need to be selected, and surface treatment processes such as polishing and grinding should be combined to remove the modified layer, improve the mold surface quality, and enhance the fatigue resistance of the mold.

Many factors during the use of injection – molding molds also have an important impact on their lifespan. The characteristics of the injection – molding material are one of them. Different plastic materials vary in fluidity, abrasiveness, and corrosiveness. For example, plastics containing reinforcing materials such as glass fibers have poor fluidity and cause more serious scouring and wear to the surface of the mold cavity during injection – molding, accelerating the wear of the mold surface and reducing the mold lifespan. Some corrosive plastics, such as polyvinyl chloride (PVC), will decompose to produce hydrogen chloride gas during injection – molding, which corrodes the mold steel, especially in a high – temperature and high – pressure injection – molding environment, the corrosion speed is faster. Whether the setting of injection – molding process parameters is reasonable is also crucial. Excessively high injection pressure and temperature will make the mold bear greater stress, exacerbating the wear and deformation of the mold; too fast injection speed will cause excessive impact of the plastic melt on the mold cavity, which is also likely to cause damage to the mold surface. The use frequency of the mold cannot be ignored either. Frequent mold opening and closing will make the various components of the mold bear alternating stress, accelerating fatigue damage and shortening the mold lifespan.

Mold maintenance is an important means to extend its service life. Regularly cleaning the mold to remove residual plastics, oil stains, and other impurities on the surface can prevent these impurities from corroding and wearing the mold surface. For example, after each injection – molding production is completed, use a special mold cleaning agent to clean the mold surface and dry the water to avoid water remaining on the mold surface and rusting. Lubricating the key components of the mold, such as guide pillars, sliders, and ejector pins, can reduce the friction between components, reduce wear, and ensure the smooth movement of the mold. Regularly checking the key parts of the mold, such as the parting surface, cavity, and core, and promptly discovering problems such as wear, deformation, and cracks, and taking corresponding repair measures can effectively prevent the problems from deteriorating further and extend the mold service life. For example, when a slight wear on the mold parting surface is found, it can be repaired by grinding to restore its flatness, ensuring the tightness of the mold and avoiding defects such as flash.

The lifespan of injection – molding molds is jointly restricted by many factors such as mold design, material selection, manufacturing process, use conditions, and maintenance. Only by strictly controlling and optimizing each link in the entire life cycle of the mold can the service life of injection – molding molds be effectively improved, creating greater economic benefits for enterprises. If you are interested in a specific aspect, such as the characteristics of a certain material or a specific maintenance method, you are welcome to continue asking questions.