Answer:

In CNC machining, grinding is a processing method that uses a high – speed rotating grinding wheel and other abrasive tools to cut and polish the surface of the workpiece at a relatively high linear speed, removing material to obtain high – precision dimensions and good surface quality. It is mainly used for the finishing of the outer circle, inner hole, plane, and formed surface of the workpiece, capable of achieving machining accuracy at the micron or even sub – micron level. It is commonly used in fields such as precision part manufacturing and mold processing.

Extended Knowledge Points:

Grinding in CNC machining is a crucial and precise processing technology that plays an indispensable role in the production of high – precision parts in modern manufacturing. The following will be elaborated in detail from multiple dimensions to introduce relevant knowledge of CNC grinding.

I. Basic Principles of CNC Grinding

CNC grinding is based on the relative movement between the abrasive tool and the workpiece. Through countless small and hard abrasive grains on the surface of the abrasive tool, micro – cutting is carried out on the surface of the workpiece. The grinding wheel is the most commonly used abrasive tool. The abrasive grains on its surface are like tiny cutting edges. When rotating at a high speed (the linear speed can reach 30 – 60m/s or even higher), they scratch, incise, and cut the material on the surface of the workpiece, causing the material to deform and gradually separate from the workpiece. Eventually, the goals of removing material, changing the shape and size of the workpiece, and improving the surface quality are achieved.

Different from traditional cutting processing, the cutting depth of grinding is small, but the cutting force per unit area is large, and a large amount of heat is generated during the grinding process. Therefore, in CNC grinding, it is crucial to precisely control the grinding parameters and dissipate heat in a timely manner to ensure machining accuracy and surface quality. The numerical control system controls the relative movement of the grinding wheel and the workpiece in multiple coordinate axis directions to achieve the grinding of complex – shaped parts, ensuring that the machining trajectory highly matches the accuracy requirements.

II. CNC Grinding Equipment

Types of CNC Grinding Machines

External Cylindrical Grinding Machine: It is mainly used for grinding the outer surfaces of rotary parts such as cylindrical and conical shapes. The workpiece is clamped on the machine tool spindle through centers, chucks, etc. and rotates. The grinding wheel reciprocates along the axial direction of the workpiece and makes a radial feed movement in the vertical direction to achieve the grinding of the outer – circle surface. It is often used for processing shaft – type parts, such as machine tool spindles and automotive drive shafts.

Internal Cylindrical Grinding Machine: It is used for grinding the inner – hole surfaces of workpieces, such as cylindrical holes and conical holes. The workpiece is usually fixed on the worktable. The grinding wheel rotates at a high speed and makes a reciprocating movement along the axis of the inner hole and a radial feed movement to complete the grinding of the inner hole. It is widely used in the processing of parts such as engine cylinder liners and bearing inner rings.

Surface Grinding Machine: It is used for grinding planes. Common types include horizontal – spindle rectangular – table surface grinding machines and vertical – spindle circular – table surface grinding machines. The horizontal – spindle rectangular – table surface grinding machine realizes plane grinding through the rotation of the grinding wheel, the reciprocating movement of the worktable in the horizontal direction, and the feed movement in the vertical direction. The vertical – spindle circular – table surface grinding machine has the grinding wheel feeding vertically downward and the circular – table worktable rotating for plane processing. It is suitable for processing the planes of various mechanical parts, such as the parting surfaces of molds and flat – plate – type parts.

Tool Grinding Machine: It is mainly used for grinding various cutting tools, such as drills, milling cutters, and taps, to ensure the geometric shape and cutting – edge accuracy of the tools to meet different processing requirements.

Profile Grinding Machine: According to the complex shape of the part, a special – shaped grinding wheel or the movement trajectory of the grinding wheel controlled by the numerical control system can be used to grind a specific formed surface. It is often used for processing mold parts with complex shapes and aero – engine blades.

Key Components of the Equipment

Spindle System: It is the core component that drives the high – speed rotation of the grinding wheel. Its rotation accuracy, rigidity, and stability directly affect the grinding accuracy and surface quality. The spindles of modern CNC grinding machines mostly use high – precision rolling bearings or hydrostatic bearings to ensure stable operation at high speeds.

Feed System: It consists of servo motors, ball screws, guide rails, etc. Under the control of the numerical control system, it realizes the precise feed movement of the grinding wheel and the workpiece in each coordinate axis direction. High – precision ball screws and linear guide rails can ensure the accuracy and stability of the feed, guaranteeing the machining dimensional accuracy.

Numerical Control System: Similar to other CNC equipment, the numerical control system is the “brain” of the CNC grinding machine. It receives the machining program, processes the instructions, and controls the movement of various components of the machine tool to achieve the automation and precise control of the grinding process. Through programming, parameters such as the movement trajectory of the grinding wheel, grinding speed, and feed rate can be set.

Cooling System: A large amount of heat is generated during the grinding process, which can easily lead to workpiece deformation, increased grinding wheel wear, and a decline in surface quality. The cooling system sprays coolant to take away the grinding heat, lubricate the surface between the abrasive grains and the workpiece, reduce friction, and at the same time wash away the abrasive chips generated during the grinding process to ensure the smooth progress of processing.

III. CNC Grinding Process

Selection of Grinding Process Parameters

Grinding Speed: Refers to the linear speed of the grinding wheel. Increasing the grinding speed can improve processing efficiency and surface quality, but it will increase the wear of the grinding wheel and the load of the machine tool. Different workpiece materials, grinding wheel materials, and processing requirements correspond to different optimal grinding speeds, generally adjusted within the range of 30 – 60m/s.

Feed Rate: Includes the longitudinal feed rate of the workpiece and the transverse feed rate of the grinding wheel. If the longitudinal feed rate is too large, the surface quality will be reduced; if the transverse feed rate is too large, the grinding force may be too large, causing workpiece deformation. It needs to be reasonably selected according to the workpiece material, machining allowance, and accuracy requirements.

Depth of Grinding: It directly affects the processing efficiency and surface quality. During rough grinding, a larger depth of grinding can be selected to quickly remove the allowance; during finish grinding, the depth of grinding is smaller, aiming to improve dimensional accuracy and surface finish.

Selection and Dressing of Grinding Wheels

Grinding Wheel Selection: Select an appropriate grinding wheel according to factors such as workpiece material, hardness, and machining accuracy. For example, when grinding hard materials (such as quenched steel), a grinding wheel with lower hardness and finer grain size should be selected; when grinding soft materials (such as copper and aluminum), a grinding wheel with higher hardness and coarser grain size can be selected. The type of abrasive of the grinding wheel (such as corundum, silicon carbide, super – abrasive) also needs to be reasonably determined according to the processing material.

Grinding Wheel Dressing: During the grinding process, the abrasive grains on the surface of the grinding wheel will gradually wear and become dull, affecting the machining accuracy and efficiency. Therefore, it is necessary to dress the grinding wheel regularly. Commonly used dressing methods include dressing with a diamond pen and dressing with a roller. The purpose of dressing is to restore the geometric shape and cutting performance of the grinding wheel and ensure the stability of grinding quality.

Planning of the Processing Process Route

For the grinding of complex parts, it is necessary to reasonably plan the processing process route. Generally, rough grinding is carried out first to remove most of the allowance, and then semi – finish grinding and finish grinding are carried out to achieve the final dimensional accuracy and surface quality requirements. During the processing, the clamping method of the workpiece and the selection of the positioning datum also need to be considered to reduce the impact of clamping errors on the machining accuracy. At the same time, according to the characteristics of the part, it may be necessary to adopt multiple clamping and step – by – step grinding methods to ensure that each surface can meet the processing requirements.

IV. Application Fields of CNC Grinding

Precision Machinery Manufacturing: In industries such as aerospace, automotive manufacturing, and high – end machine tools, many key parts (such as aero – engine turbine blades, automotive engine crankshafts, and ball screws of machine tools) need to be processed by CNC grinding to ensure their high – precision dimensions and surface quality to meet the high – performance operation requirements of the equipment.

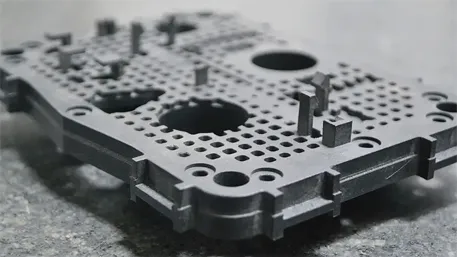

Mold Manufacturing: The accuracy of molds directly affects the quality of products. CNC grinding is often used for the processing of mold forming surfaces, parting surfaces, etc., ensuring the dimensional accuracy and surface finish of the molds, so as to produce high – precision plastic products, stamping parts, etc.

Electronic Manufacturing: With the miniaturization and precision development of electronic products, the requirements for part accuracy are extremely high. CNC grinding can be used to process precision parts of electronic components, such as precision molds for mobile phone casings and processes such as grinding and polishing in semiconductor chip manufacturing.

Medical Device Manufacturing: Medical devices have strict requirements for the accuracy and surface quality of parts. CNC grinding technology can meet the processing needs of parts such as artificial joints and surgical instruments, ensuring their safety and reliability.

Grinding in CNC machining is an advanced processing technology that integrates multi – disciplinary knowledge such as precision machinery, numerical control technology, and materials science. From basic principles to equipment composition, from process parameter selection to application fields, each link is interrelated and mutually influential. In – depth understanding and mastery of CNC grinding knowledge are of great significance for improving the processing level of precision parts and promoting the high – quality development of the manufacturing industry. If you want to know more detailed application cases of CNC grinding in a specific field or other relevant knowledge, you are welcome to communicate at any time!