Answer:

Grinding and milling are two different processes in CNC machining. Their main differences lie in processing tools, machining accuracy, processing methods, and application scenarios. Grinding uses abrasive tools such as grinding wheels, and through the micro – cutting of abrasive grains, the accuracy can reach the micron level or even higher, which is often used for finishing. Milling uses milling cutters, and removes materials through the rotating cutting edges. Its accuracy is generally lower than that of grinding, and it is often used for roughing and semi – finishing. In addition, grinding is suitable for the processing of high – precision surfaces and hard materials, while milling is better at processing complex contours and planes.

Extended Knowledge Points:

In the field of CNC machining, although both grinding and milling belong to material removal processing methods, there are many differences between them in terms of principles, equipment, processes, and applications. The following will explore the differences between them in depth from multiple perspectives.

I. Differences in Processing Tools and Cutting Principles

Grinding Tools and Principles

Grinding mainly relies on the grinding wheel as the processing tool. The surface of the grinding wheel is covered with a large number of small and hard abrasive grains, which are equivalent to tiny cutting edges. During processing, the grinding wheel rotates at a high speed (the linear speed is usually 30 – 60m/s or even higher). The abrasive grains scratch, incise, and micro – cut the surface of the workpiece, gradually removing the workpiece material. Due to the small size of the abrasive grains and the shallow cutting depth, grinding belongs to micro – cutting processing. The amount of material removed each time is very small, enabling extremely high machining accuracy and good surface quality.

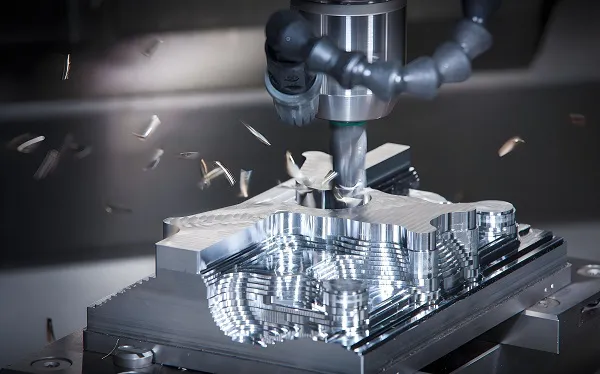

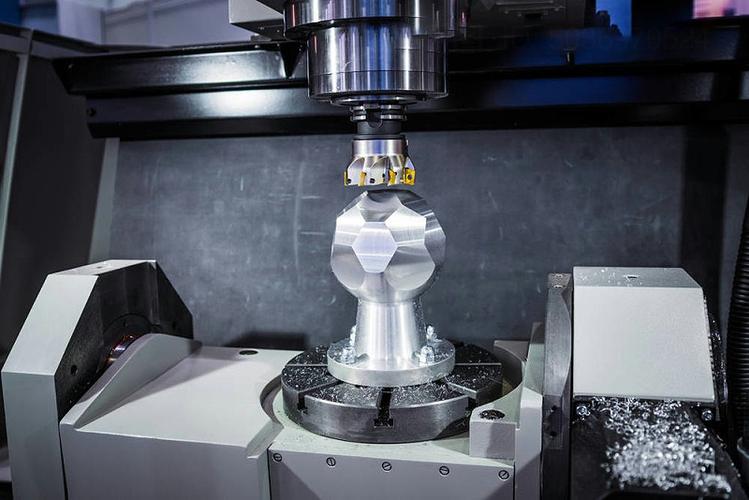

Milling Tools and Principles

The tool used in milling is a milling cutter. The milling cutter has multiple cutting edges, and common ones include end mills, end – mills, and face – mills. During the milling process, the milling cutter rotates at a high speed and moves in a specific direction at the same time. The cutting edges are used to cut the workpiece, removing the material layer by layer. The cutting edges of the milling cutter are relatively large in size, and the cutting depth and feed rate are also larger than those of grinding. Therefore, the material removal efficiency of milling is high, but the machining accuracy is relatively low.

II. Comparison of Machining Accuracy and Surface Quality

Accuracy and Surface Quality of Grinding

Grinding can achieve extremely high dimensional accuracy and surface finish. Its machining accuracy can usually reach the micron level (μm), and even under ultra – precision grinding technology, sub – micron (0.1 – 1μm) or nanometer (nm) accuracy can be achieved. The surface roughness Ra value after grinding can reach a very low level, for example, 0.1 – 0.8μm, which is suitable for the processing of parts with extremely high requirements for accuracy and surface quality, such as precision bearings, precision molds, and optical lenses.

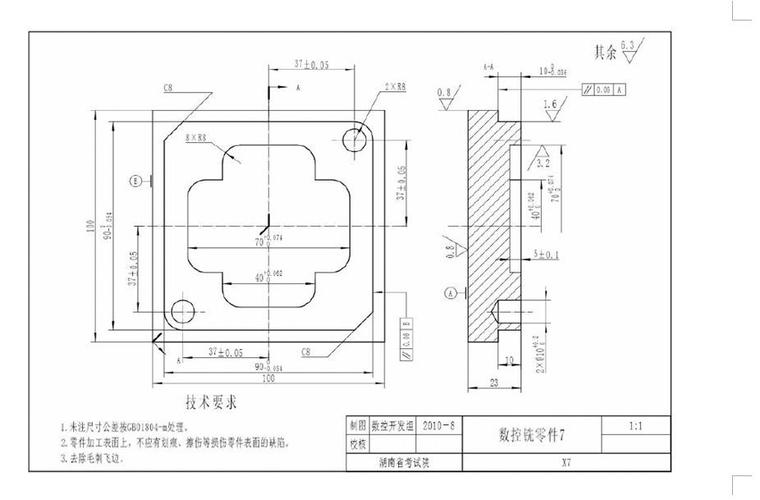

Accuracy and Surface Quality of Milling

The machining accuracy of milling is generally between 0.01 – 0.1mm, and the surface roughness Ra value is usually between 1.6 – 12.5μm. Although the accuracy of milling is not as high as that of grinding, by optimizing the tool, cutting parameters, and processing technology, it can also meet the accuracy requirements of many parts. Milling is often used for roughing to remove a large amount of material and for semi – finishing to prepare for subsequent finishing. In the processing of some parts with not particularly strict accuracy requirements, milling can also be used as the final processing procedure.

III. Differences in Processing Equipment and Movement Modes

Grinding Equipment and Movement

CNC grinding machines are the main equipment for grinding. According to different processing objects and methods, they can be divided into external cylindrical grinding machines, internal cylindrical grinding machines, surface grinding machines, tool grinding machines, etc. During the grinding process, the high – speed rotation of the grinding wheel is the main movement. The workpiece, depending on the type of grinding machine, rotates (such as the workpiece rotates during external cylindrical grinding), moves linearly (such as the worktable moves linearly during surface grinding), or a combination of both. At the same time, the grinding wheel also makes a feed movement in the direction perpendicular to the workpiece surface to control the grinding depth.

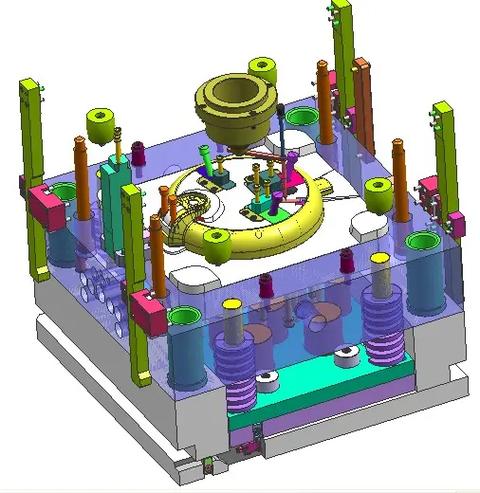

Milling Equipment and Movement

CNC milling machines and machining centers are the main equipment for milling. During milling, the rotation of the milling cutter is the main movement, and the linear movement of the workpiece or the milling cutter is the feed movement. A CNC milling machine generally has three linear motion coordinate axes (X, Y, Z axes), and some high – end equipment also has rotating axes (such as A, B, C axes) to achieve multi – axis linkage processing. A machining center, based on a CNC milling machine, is equipped with a tool magazine and an automatic tool – changing device, enabling the completion of various milling and other processing procedures (such as drilling, boring, tapping, etc.) in one clamping.

IV. Comparison of Processing Efficiency and Material Removal Rate

Processing Efficiency of Grinding

Since grinding is micro – cutting and the amount of material removed each time is small, its material removal rate is relatively low, and the processing efficiency is not high. Especially when the machining allowance is large, grinding requires multiple passes to complete the processing, which takes a long time. However, in the finishing stage, grinding can quickly meet the high – precision requirements. From the perspective of ensuring processing quality, its efficiency still has advantages in specific scenarios.

Processing Efficiency of Milling

The cutting edges of milling are relatively large in size, and the cutting depth and feed rate are also large. Therefore, the material removal rate is high, and the processing efficiency is much higher than that of grinding. In the roughing stage, milling can quickly remove a large amount of material, greatly shortening the processing time, so it is widely used in the early processing procedures of parts.

V. Differences in Application Scenarios

Application Fields of Grinding

Grinding is often used for the finishing of precision parts, such as the precision processing of engine blades and turbine disks in the aerospace field; the surface grinding of crankshafts and camshafts in the automotive manufacturing; the finishing of mold forming surfaces and parting surfaces in mold manufacturing; and the grinding and polishing of semiconductor chips in electronic manufacturing. In addition, for materials with high hardness (such as quenched steel, cemented carbide, etc.), grinding is also the main processing method.

Application Fields of Milling

Milling is widely used in mechanical manufacturing, especially suitable for processing parts with complex shapes, such as various box – type parts, mold cavities and punches, automotive cover – panel molds, etc. It can perform planar milling, contour milling, and can also process complex three – dimensional surfaces through multi – axis linkage. In product development and small – batch production, the flexibility and high efficiency of milling make it one of the preferred processing methods.

In summary, grinding and milling each have their own characteristics and advantages in CNC machining and are suitable for different processing requirements. Understanding the differences between them helps to reasonably select the processing technology according to factors such as part materials, accuracy requirements, structural shapes, and production batches in actual production, thereby improving production efficiency and product quality. If you want to know other specific contents about grinding and milling, welcome to leave a message in the comment section for discussion!

The above has compared the differences between grinding and milling from multiple aspects. If you want to understand a certain difference point in depth or have other processing technology comparison needs, feel free to let me know.