With the advantages of high precision and personalized customization, 3D printing technology is reshaping the landscape of the medical industry. From customized implants to intelligent surgical guides, this technology provides precise solutions to medical challenges through material innovation and process breakthroughs. This article deeply analyzes the technical advantages and development potential of customized 3D – printed medical parts services from the core dimensions such as technical principles, material characteristics, and clinical applications, combined with data and cases.

I. Analysis of the Core Technologies of 3D – printed Medical Parts

Selective Laser Melting (SLM), Stereolithography (SLA/DLP), and bioprinting constitute the three core technologies in the medical field. The SLM technology uses a high – power laser to melt titanium alloy powder layer by layer, with a forming accuracy of ±0.05mm, and is widely used in the manufacturing of orthopedic implants. The SLA technology cures photosensitive resin with ultraviolet light, with a layer thickness as low as 0.025mm, and occupies a 75% market share in the production of surgical guides. Bioprinting combines biomaterials with living cells. The equipment developed by Tsinghua University has an accuracy of 0.05 microliters, bringing breakthroughs to tissue engineering.

II. Performance and Application of Medical – grade 3D – printing Materials

Medical 3D – printing materials need to balance biocompatibility and mechanical properties. Among metallic materials, titanium alloy, with its high strength and non – rejection characteristics, accounts for more than 60% of the implant market. For example, Aikang Medical’s 3D – printed acetabular cup has passed the CFDA certification. In terms of polymer materials, biodegradable polylactic acid (PLA) is used for disposable surgical guides, and photosensitive resin is the first choice for model making due to its high resolution. Bioceramic materials show unique advantages in the field of dental restoration. The hardness of zirconia all – ceramic crowns reaches 800HV, comparable to natural tooth enamel.

III. Application Scenarios of Customized 3D – printed Medical Parts

In the orthopedic field, 3D – printed surgical guides have reduced the intracerebral hemorrhage surgery time at the First People’s Hospital of Guiyang County to within 1 hour and decreased blood loss by 30%. The customized titanium alloy acetabular cup at Linyi People’s Hospital has shortened the femoral head necrosis surgery time from 3 hours to 40 minutes. In the direction of tissue engineering, the boron – based glass scaffold developed by the Chinese Academy of Sciences has a porosity of 60% – 80%, and animal experiments have shown a 230% increase in osteogenesis efficiency. In the drug delivery system, 3D – printed sustained – release pills have been approved by the FDA, achieving precise drug release through a porous structure.

IV. Quality Control System for 3D – printed Medical Parts

Medical – grade 3D printing must strictly follow the ISO 13485 medical device quality management system. During the production process, an AI algorithm is used to monitor 12 key parameters such as temperature and stress in real – time, controlling the printing failure rate within 5%. For finished – product inspection, double verification by CT scanning and mechanical property testing is carried out to ensure that the parts meet the ASTM F136 medical standard. Some enterprises have achieved full – process digital traceability from design modeling to finished – product delivery, ensuring that product quality is traceable and controllable.

V. Cost – optimization Paths for 3D – printed Medical Parts

Technological iteration has significantly reduced costs. The equipment procurement cost has decreased by 30% compared to five years ago, and the price of titanium alloy powder is expected to drop by another 40% by 2030. Taking knee – joint replacement surgery as an example, the cost of 3D – printed implants has dropped from 80,000 yuan to 45,000 yuan, a decrease of 43.75%. Mass production and the substitution of domestic materials have become the main driving forces for cost reduction. In some regions, specific 3D – printed medical consumables have been included in the medical insurance reimbursement scope, further improving accessibility.

VI. Policies and Regulations for the 3D – printed Medical Industry

The China Food and Drug Administration has opened a special approval channel for Class III medical devices, reducing the average approval cycle from 18 months to 9 months. Seventeen 3D – printed products have been approved through the innovation channel. Local governments such as Guangdong and Jiangsu have introduced industrial cluster policies, providing R & D subsidies and tax incentives to promote enterprise technological upgrading. Internationally, the EU’s “Regulation on Advanced Therapy Medicinal Products” provides a reference for the standardized development of the industry and accelerates the clinical translation of technology.

VII. Detailed Explanation of the Process for Customized 3D – printed Medical Parts

Demand Communication and Data Collection: Obtain the patient’s anatomical data through medical images such as CT and MRI, and clarify the part specifications and performance indicators in combination with the doctor’s clinical needs.

3D Modeling and Design Optimization: Use software such as Mimics and 3DSlicer to convert medical data into 3D models, and ensure structural strength and adaptability through topology optimization and finite – element analysis.

Material and Process Selection: Determine the material according to the application scenario (such as titanium alloy for implants, PLA for guides) and match it with corresponding processing technologies such as SLM and SLA.

Printing and Post – processing: After 3D printing, the parts are subjected to treatments such as support removal, surface polishing, and high – temperature sterilization to ensure compliance with medical standards.

Quality Inspection and Delivery: Pass more than 10 inspections such as dimensional measurement and biocompatibility testing, and deliver to hospitals or patients for use after passing.

VIII. Inventory of Processing Technologies for 3D – printed Medical Parts

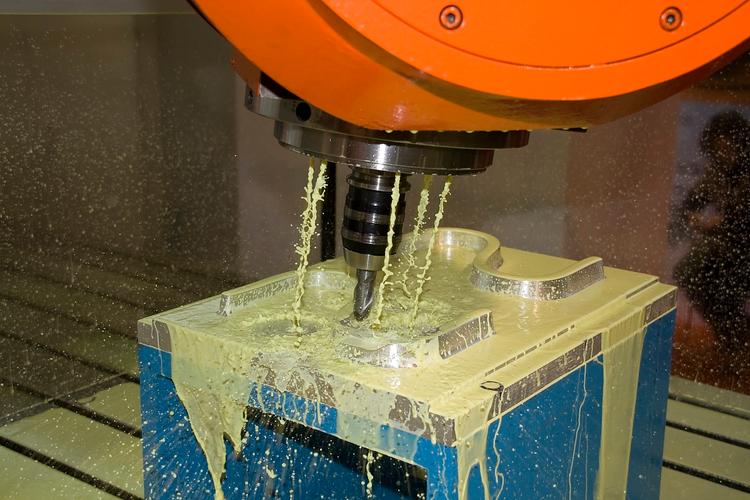

Selective Laser Melting (SLM): Suitable for metallic materials such as titanium alloy and stainless steel. High – energy lasers are used to melt powder layer by layer to manufacture high – strength parts with a density of over 99%.

Stereolithography (SLA/DLP): Cures photosensitive resin with ultraviolet light, suitable for making high – precision surgical guides and medical models, with a layer – thickness accuracy of up to 0.025mm.

Fused Deposition Modeling (FDM): Extrudes heated thermoplastic materials (such as PLA and ABS) layer by layer for stacking and forming, often used to manufacture low – cost medical teaching aids and auxiliary tools.

Bioprinting: Combines biomaterials with cell printing, used for constructing tissue – engineering scaffolds and organoid models, and supports multi – material composite printing.

IX. Frequently Asked Questions about Customized 3D – printed Medical Parts

Q1: How long does it take to customize 3D – printed medical parts?

A: From data collection to finished – product delivery, the normal process takes 7 – 15 working days. For urgent needs, it can be shortened to 3 – 5 days through the green channel.

Q2: How is the safety of 3D – printed medical parts ensured?

A: All products have passed the ISO 13485 quality system certification, use medical – grade materials, and undergo strict tests such as biocompatibility and mechanical properties.

Customized 3D – printed medical parts are driving changes in the medical industry through technological innovation. Whether it is optimizing complex surgical plans or customizing personalized rehabilitation devices, we can provide professional solutions. If you have cooperation needs or technical inquiries, please leave a message in the comment area, and we will provide you with one – to – one professional answers!