I. What is Angle Milling?

Angle milling is a crucial branch of milling processing technology. It refers to the machining method of using milling cutters with specific angles to create features such as planes, grooves, contours, or inclined surfaces with specific angles on workpieces. By controlling the angle of the cutter, cutting parameters, and the movement trajectory of the machine tool, it is possible to achieve the machining of various complex angular structures, which has a wide range of applications in numerous fields such as mechanical manufacturing, mold processing, and aerospace.

According to different machining objects and purposes, angle milling can be divided into various types. Common ones include inclined plane milling, which is used to machine planes with a certain inclination angle; groove angle milling, used for machining grooved structures with angles; and contour angle milling, applied to machining parts with complex angular contours. Different types of angle milling vary in cutter selection, machining processes, and parameter settings.

II. Characteristics of Angle-Milled Parts

2.1 High Geometric Accuracy

Angle milling enables high-precision angle machining. With advanced CNC control systems and high-precision machine tools, the angular error can be controlled within the range of ±0.01° – ±0.05°. For example, in mold manufacturing, the angle accuracy requirements of the parting surfaces of precision molds are strict. The angle milling process can meet these high-precision requirements, ensuring the assembly accuracy and molding quality of the molds.

2.2 Good Surface Quality

By reasonably selecting cutters and cutting parameters, angle milling can achieve excellent surface quality. The surface roughness Ra value usually reaches 0.8 – 3.2μm. For parts with high surface quality requirements, such as the wing connection components in the aerospace field, after angle milling, not only can the angle accuracy be guaranteed, but also the surface finish requirements can be met, reducing stress concentration and improving the fatigue strength of the parts.

2.3 Strong Structural Adaptability

Angle milling can machine a variety of complex angular structures. Whether it is an acute angle, an obtuse angle, or a composite angular structure, precise machining can be achieved through programming control. This process can meet the diverse angular design requirements of parts in different industries. For instance, in automotive parts manufacturing, various brackets and connecting parts with special angles can all be completed by angle milling.

III. How is Angle Milling Performed?

3.1 Preparation before Machining

Before performing angle milling, first, construct a 3D model using computer-aided design (CAD) software according to the part design drawings, and then generate a numerical control machining program through computer-aided manufacturing (CAM) software. At the same time, select appropriate angle milling cutters based on the properties (such as hardness and toughness) of the machining material and the machining requirements. Parameters such as the angle, diameter, and number of teeth of the angle milling cutter directly affect the machining effect. For example, when machining alloy steel with high hardness, cemented carbide angle milling cutters with fewer teeth can be selected to improve cutting efficiency and tool durability. In addition, suitable fixtures need to be prepared to ensure accurate positioning and firm clamping of the workpiece during machining.

3.2 Machining Process

Clamp the prepared workpiece on a CNC milling machine, accurately align and set the tool with the workpiece through the coordinate system of the machine tool to determine the relative position between the cutter and the workpiece. According to the generated numerical control program, the machine tool controls the angle milling cutter to machine the workpiece. During the machining process, cutting parameters, including spindle speed, feed rate, and cutting depth, need to be precisely controlled. Generally, for angle milling of ordinary steel, the spindle speed is controlled at 800 – 1500 revolutions per minute, the feed rate at 50 – 150 mm per minute, and the cutting depth at 0.5 – 3 mm. Meanwhile, the rational use of cutting fluid can effectively reduce the cutting temperature, reduce tool wear, and improve the machining surface quality. Common cutting fluids include emulsions, cutting oils, and water-based cutting fluids, and the selection should be based on specific machining materials and process requirements.

3.3 Post-processing

After machining is completed, clean the parts to remove residual cutting fluid, iron chips, and other impurities on the surface. Then, use measuring tools (such as angle gauges, dial indicators, and coordinate measuring machines) to detect the angle accuracy, dimensional accuracy, and surface roughness of the parts to ensure that the parts meet the design requirements. For parts with extremely high precision requirements, subsequent finishing processes such as grinding and polishing may be required.

IV. Difficulties in Angle Milling

4.1 Rapid Tool Wear

In angle milling, due to the continuous change in the contact area and cutting angle between the cutting edge of the tool and the workpiece, especially when machining materials with high hardness or large toughness, the tool bears large cutting forces and heat, resulting in rapid tool wear. For example, when machining angular structures of titanium alloy materials, the tool wear rate is 3 – 5 times faster than that of machining ordinary carbon steel. This not only increases the tool cost but also affects the machining efficiency and accuracy.

4.2 Difficulty in Controlling Angle Accuracy

For angle machining with extremely high precision requirements, such as the angular components in precision instruments, it is challenging to control the angle accuracy due to various factors during the machining process, including cutting forces, thermal deformation, and machine tool vibration. Even with high-precision machine tools and advanced machining processes, angular deviations may still occur. To control the angular error within a very small range (such as ±0.005°), the machining process needs to be finely optimized, including reasonably selecting cutters, optimizing cutting parameters, and enhancing the rigidity and stability of the machine tool.

4.3 Low Machining Efficiency for Complex Structures

When machining parts with complex composite angular structures, the programming and machining processes are complex because the cutter angle and machining direction need to be changed multiple times, resulting in low machining efficiency. For example, the machining time of a mold part with multiple inclined surfaces and grooves at different angles may be 3 – 5 times that of ordinary plane milling. In addition, the machining of complex structures also requires high technical proficiency and experience from programmers, increasing the machining cost.

V. Characteristics Table of CNC Angle-Milled Parts

VI. How to Customize CNC Angle-Milled Parts?

6.1 Clarify Requirements

Communicate fully with customers to understand in detail the usage scenarios, functional requirements, precision standards, appearance requirements, and required quantity of the parts. Customers are required to provide detailed part design drawings. If there are no drawings, a professional design team can design according to customer requirements. For example, for CNC angle-milled parts in the aerospace field, it is necessary to clarify their specific positions in the aircraft and the load-bearing conditions to determine reasonable precision and material requirements.

6.2 Select a Machining Manufacturer

Choose a manufacturer with rich angle milling experience, advanced CNC machining equipment, and a professional technical team. Review the manufacturer’s past cases and customer reviews to evaluate their machining capabilities and quality control levels. It is advisable to conduct on-site inspections of the manufacturer to understand its production scale, equipment status, and management level. For example, for customizing high-precision angle-milled parts, select a manufacturer equipped with high-precision five-axis CNC milling machines and advanced testing equipment (such as laser interferometers and coordinate measuring machines).

6.3 Quotation and Order Placement

The machining manufacturer quotes based on factors such as the complexity of the parts, material costs, machining processes, and quantity. After the customer approves the quotation, both parties sign a machining contract, clearly defining machining requirements, delivery time, price, payment method, and other terms. After the customer pays the advance payment, the manufacturer officially arranges production.

VII. Machining Process of CNC Angle-Milled Parts

7.1 Drawing Design and Review

Design the drawings according to customer requirements. After the design is completed, organize professionals to review the drawings to ensure that the dimensional markings are accurate and the technical requirements are clear and reasonable, avoiding machining errors caused by drawing problems. For complex angular structures, multiple design optimizations and simulation analyses may be required to ensure machining feasibility.

7.2 Material Procurement and Inspection

Purchase suitable materials according to the requirements of the drawings. Conduct strict inspections on the purchased materials, checking whether the specifications, hardness, chemical composition, etc., meet the standards to ensure the quality of the materials. For example, for high-strength alloy steel materials, mechanical property tests such as tensile tests and impact tests are required.

7.3 CNC Angle Milling

Perform angle milling on a CNC milling machine according to the established machining process and numerical control program. Monitor the machining status in real-time during the machining process and adjust the parameters in a timely manner to ensure machining accuracy and quality. For key processes, online inspection links can be set up to conduct real-time measurement and feedback of machining dimensions and angles.

7.4 Quality Inspection

Conduct a comprehensive quality inspection of the machined parts. The inspection items include angle accuracy, dimensional accuracy, surface roughness, and geometric tolerances to ensure that the parts meet the design and customer requirements. Use a variety of inspection methods, such as measuring angles with angle gauges, dimensions with micrometers, and surface roughness with roughness testers.

7.5 Surface Treatment

Select appropriate surface treatment processes, such as galvanizing, chrome plating, painting, and passivation, according to the usage environment of the parts and the customer’s appearance requirements to improve the corrosion resistance and aesthetics of the parts.

7.6 Packaging and Delivery

Package the parts that have passed the inspection and completed the surface treatment. Select suitable packaging materials to ensure that the parts are not damaged during transportation. Deliver the parts to the customer according to the delivery time and method stipulated in the contract.

VIII. Machining Technologies for CNC Angle-Milled Parts

8.1 High-Speed Angle Milling Technology

High-speed angle milling technology significantly shortens the machining time while ensuring machining quality by increasing the spindle speed and feed rate of the machine tool. With high-speed angle milling technology, the spindle speed can reach 15,000 – 40,000 revolutions per minute, and the feed rate can reach 3 – 8 meters per minute, effectively improving machining efficiency and reducing production costs. Meanwhile, most of the cutting heat generated by high-speed cutting is carried away by the chips, reducing the thermal deformation of the workpiece and contributing to improving machining accuracy.

8.2 Five-Axis Simultaneous Angle Milling Technology

Five-axis simultaneous machining technology enables the one-time machining of complex angular structures. Through the coordinated movement of five axes, the cutter can cut the workpiece at various angles and postures. For parts with complex composite angles, using five-axis simultaneous angle milling technology can reduce the number of clamping times, avoid positioning errors caused by multiple clampings, and improve machining accuracy and surface quality. For example, when machining the blade tenons of aircraft engines (which have complex multi-angle structures), five-axis simultaneous angle milling technology can significantly enhance machining efficiency and accuracy.

8.3 Minimum Quantity Lubrication (MQL) Angle Milling Technology

The MQL angle milling technology sprays a tiny amount of lubricating oil mist into the cutting area using compressed air as the carrier during the machining process, playing a role in lubrication and cooling. Compared with the traditional cutting fluid cooling method, the amount of lubricating oil used in this technology is extremely small (a few milliliters per minute), which not only reduces the environmental pollution caused by cutting fluids but also lowers production costs. At the same time, MQL can effectively reduce the cutting temperature, reduce tool wear, and improve the machining surface quality.

IX. Machining Equipment for CNC Angle-Milled Parts

9.1 Three-Axis CNC Milling Machines

Three-axis CNC milling machines are the most basic angle milling equipment. They can achieve the coordinated movement of three linear axes (X, Y, and Z axes) and can complete the machining of simple angular planes, grooves, etc. They are suitable for machining angle-milled parts with relatively low precision requirements and simple structures. Their positioning accuracy is generally within the range of ±0.01mm – ±0.02mm, and the repeat positioning accuracy is within the range of ±0.005mm – ±0.01mm.

9.2 Five-Axis Simultaneous CNC Milling Machines

Five-axis simultaneous CNC milling machines add two rotary axes (A-axis, B-axis, or C-axis) based on the three axes, enabling the coordinated control of five axes. They have higher machining flexibility and accuracy and can machine various parts with complex angular structures. Their positioning accuracy can reach ±0.005mm, and the repeat positioning accuracy can reach ±0.002mm, which are widely used in high-end fields such as aerospace and mold manufacturing.

9.3 High-Speed CNC Milling Machines

High-speed CNC milling machines are equipped with high-speed spindle systems and rapid feed systems. The maximum spindle speed can reach more than 40,000 revolutions per minute, and the feed rate can reach 40 meters per minute. They are suitable for high-speed angle milling, which can improve machining efficiency and surface quality and are often used for angle milling of light metal materials such as aluminum alloys and magnesium alloys.

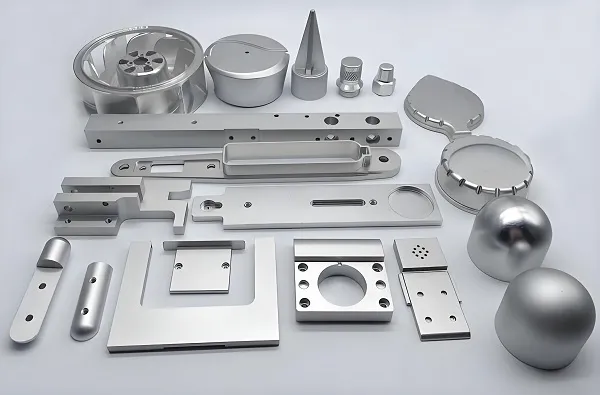

X. Application Fields of CNC Angle-Milled Parts

10.1 Aerospace

In the aerospace field, CNC angle-milled parts are widely used in the manufacturing of aircraft fuselage structural components, engine parts, and aerospace molds. For example, the connecting angle materials of aircraft wings, the tenons, and mortises of engine blades, etc., all require high-precision angle milling to ensure their angle accuracy and surface quality, meeting the strict requirements for the reliability and performance of aerospace products.

10.2 Mold Manufacturing

In mold manufacturing, the angle milling process is often used to machine the parting surfaces of molds, inclined surfaces of sliders, grooves of inclined ejectors, and other parts. Through precise angle milling, the assembly accuracy and molding quality of the molds can be guaranteed, and the service life of the molds can be extended. For example, automotive cover molds, injection molds, etc., all rely on the application of the angle milling process.

10.3 Automotive Manufacturing

In automotive manufacturing, various components with special angles, such as the connecting angle parts of engine intake and exhaust manifolds, and the brackets and steering knuckles of the automotive chassis, can all be completed by CNC angle milling. The angle milling process can meet the precision and efficiency requirements for the mass production of automotive components.

10.4 Mechanical Equipment

In the manufacturing of various mechanical equipment, CNC angle-milled parts are used to manufacture various transmission components and connecting components. For example, the guide rail sliders of machine tools, the angular surfaces of gearbox casings, etc., can ensure the assembly accuracy and transmission performance between parts through angle milling.

XI. Customization of CNC Angle-Milled Parts

11.1 Customization Advantages

Customizing CNC angle-milled parts enables personalized production according to the unique needs of customers, meeting the requirements for special angular structures and precision of parts in different industries and scenarios. Through customization, precise control can be achieved in material selection, dimensional accuracy, surface quality, etc., thereby improving the adaptability and performance of the parts. At the same time, customized production can effectively avoid possible performance redundancies or deficiencies of general-purpose parts, reducing costs and improving production efficiency.

11.2 Customization Process

The customization process of CNC angle-milled parts generally includes links such as demand communication, drawing design, process planning, machining and manufacturing, quality inspection, surface treatment, and packaging and delivery. In the demand communication stage, communicate in-depth with customers to clarify all requirements of the parts; in the drawing design stage, draw detailed design drawings according to the requirements; in the process planning stage, determine the machining process and parameters; in the machining and manufacturing stage, carry out actual machining according to the plan; in the quality inspection stage, ensure that the part quality meets the standards; in the surface treatment stage, enhance the corrosion resistance and appearance of the parts; and finally, package and deliver the parts to the customer.

XII. Common Problems of CNC Angle-Milled Parts

12.1 Angular Deviation

During the machining process, angular deviation of parts may occur due to reasons such as tool wear, unreasonable cutting parameters, or a decline in machine tool accuracy. Solutions include regularly checking and replacing tools, optimizing cutting parameters, and regularly detecting and maintaining the accuracy of the machine tool.

12.2 Surface Quality Defects

Problems such as non-compliance with surface roughness requirements, scratches, and burns may occur. These may be caused by factors such as excessive cutting speed, large feed rate, improper use of cutting fluid, or wear of the tool edge. Improvements can be made by adjusting cutting parameters, reasonably selecting and using cutting fluid, and replacing tools in a timely manner.

12.3 Cutting Vibration

In angle milling, cutting vibration affects machining accuracy and surface quality and may even lead to tool breakage. Cutting vibration may be caused by factors such as insufficient machine tool rigidity, improper tool installation, and unreasonable cutting parameters. Vibration can be reduced by increasing machine tool rigidity, correctly installing tools, and optimizing cutting parameters.

XIII. Conclusion

If you have any questions or needs regarding the customization of CNC angle-milled parts, please feel free to leave us a message for consultation! We have advanced CNC machining equipment and a professional technical team, and we have accumulated rich experience in the field of angle milling. We have successfully completed over a thousand customization projects for high-precision angle-milled parts in many industries, such as aerospace and mold manufacturing, with a customer satisfaction rate of up to 98%. Whether you need single-piece customization or mass production, we can meet your requirements with exquisite craftsmanship, strict quality control, and reasonable prices. Leave a message now