Answer

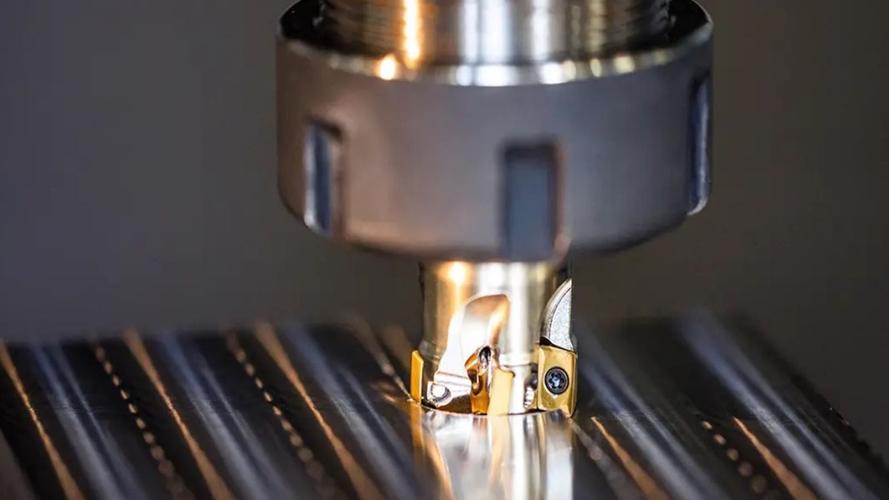

CNC side milling is a machining process that uses a Computer Numerical Control (CNC) system to control a milling cutter, where the side edges of the cutter are used to remove material from the workpiece. It is primarily used for machining side profiles, grooves, stepped surfaces, etc., featuring high precision, efficiency, and automated control.

Extended Response

I. Basic Principles and Technical Characteristics of CNC Side Milling

1. Machining Principle

- Tool and Movement: The side edges (cylindrical cutting edges) of the milling cutter are the primary cutting components. The cutter axis is usually parallel or angled relative to the workpiece surface. The CNC system controls the of XYZ axes (and rotational axes) to move the cutter along a predefined path, enabling side cutting.

- Cutting Mechanism: During side milling, the cutter’s side edges continuously or intermittently penetrate the workpiece. The cutting thickness varies with the cutter’s position, generating radial cutting forces that require optimized tool paths to reduce vibration.

2. Key Technical Features

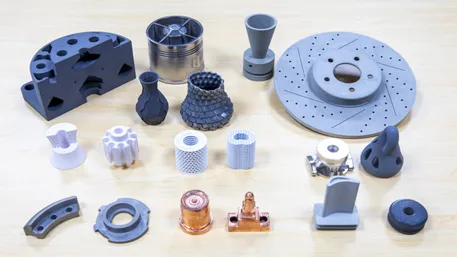

- High Precision: CNC systems enable micron-level positioning, suitable for complex surfaces and precise profiles (e.g., mold cavities, aerospace thin-walled structures).

- Flexible Production: Adaptable to different part geometries via program modifications, ideal for small-batch, high-mix production.

- Cutting Efficiency: Outperforms manual methods through high-speed cutting and multi-flute tools, especially for long straight edges and large-area side surfaces.

II. Application Areas and Typical Scenarios

1. Aerospace Industry

- Components: Aircraft wing skins, fuselage frames, engine blade root slots.

- Requirements: Side milling for thin-walled parts requires controlled cutting forces to prevent deformation, with surface roughness ≤Ra 0.8μm.

2. Mold Manufacturing

- Applications: Sidewalls of injection molds, parting surfaces of die-casting molds, edge profiles of stamping dies.

- Advantages: 5-axis side milling enables complex undercut structures, reducing Electrical Discharge Machining (EDM) processes and shortening mold production cycles.

3. Automotive Components

- Typical Parts: Side holes in transmission cases, grooves in engine blocks, door mold profiles.

- Efficiency Needs: Side milling combined with High-Speed Cutting (HSC) improves mass production efficiency while maintaining precision.

4. Electronics & Medical Devices

- Precision Parts: Grooves in medical device housings, side slots in electronic heat sinks, requiring high precision (±0.01mm) and low surface roughness.

III. Key Processes and Equipment Requirements

1. Tool Selection

- End Mills: Most common for straight sidewalls and grooves, diameters range from 1-100mm with varying flute lengths.

- Waveform Mills: For deep side milling, dispersing cutting forces to reduce vibration, suitable for cast iron and aluminum alloys.

- Ball Nose/Radius Mills: For curved side surfaces or fillet transitions, e.g., mold R-corners.

2. Equipment and CNC System Requirements

- Machine Types:

- Vertical Machining Centers: Ideal for vertical side surfaces of medium-small parts.

- Horizontal Machining Centers: Combined with rotary tables for multi-sided milling.

- 5-Axis Machining Centers: Enable angled and complex surface milling (e.g., impeller blades).

- CNC Systems: Must support multi-axis interpolation (e.g., FANUC, SIEMENS) with look-ahead 功能 for optimized high-speed trajectories.

3. Process Parameter Optimization

- Cutting Speed (V): Material-dependent (e.g., 150-300m/min for aluminum, 80-150m/min for steel).

- Feed Rate (F): Radial engagement (stepover) typically 10%-50% of tool diameter; axial depth Restricted by tool overhang to avoid chatter.

- Coolant: Emulsions for steel, air or Minimum Quantity Lubrication (MQL) for aluminum to reduce tool adhesion.

IV. Comparison with Other Machining Methods

| Method | CNC Side Milling | Face Milling | Turning | EDM |

|---|---|---|---|---|

| Cutting Edge | Side edges for profiles | End edges for flat surfaces | Tool moves axially on rotating workpiece | Electrodes erode material |

| Efficiency | Efficient for long edges | High for flat surfaces | High for rotational parts | Low for complex profiles |

| Precision | Up to ±0.02mm, Ra1.6 | High flatness, side precision depends on setup | High for rotational sides | Up to ±0.01mm, smooth surface |

| Material | Metals (steel, aluminum, titanium) | Same as above | Ideal for rotational parts | Hard materials (e.g., hardened steel) |

| Cost | Moderate tooling, high equipment | Low tooling, moderate equipment | Low equipment cost | High electrode cost, low efficiency |

V. Common Issues and Solutions

1. Cutting Vibration (Chatter)

- Cause: Excessive tool overhang, unbalanced cutting forces, improper parameters.

- Solution: Shorten tool overhang, use anti-vibration tool holders; adjust speed/feed to avoid resonant frequencies; optimize entry paths (e.g., helical vs. perpendicular entry).

2. Side Precision Deviation

- Cause: Machine rigidity issues, tool wear, programming errors.

- Solution: Check machine clearances, replace worn tools; use tool radius compensation (G41/G42) and adjust via test cuts.

3. Poor Surface Roughness

- Cause: Improper parameters, dull tool edges, inadequate cooling.

- Solution: Increase cutting speed (HSC improves surface finish), reduce feed rate; use coated tools (e.g., TiAlN) and enhance cooling.

VI. Technological Trends

- High-Speed & 5-Axis Technology: 5-axis side milling enables single-setup machining of complex surfaces (e.g., aerospace blisks), while HSC (spindle speeds >10,000rpm) reduces thermal deformation.

- Intelligent Machining: Real-time monitoring of cutting forces/vibration via sensors, combined with AI algorithms for adaptive parameter optimization.

- Green Manufacturing: Promotion of MQL and dry cutting to reduce coolant waste and costs.

- Hybrid Machining: Integration of side milling with turning/drilling in multi-task machines for complete part processing in one setup.

VII. Conclusion

CNC side milling, leveraging precise CNC control and side-edge cutting, is a core method for precision side machining in modern manufacturing. Its applications span aerospace, molds, and automotive industries, evolving toward high-speed, intelligent, and sustainable practices through tool innovation, equipment upgrades, and process optimization. Understanding its principles is crucial for enhancing the quality and efficiency of complex part manufacturing.