I. Definition of CNC Face Milling

CNC face milling, namely Computer Numerical Control Face Milling, is a machining process. It uses a rotating milling cutter to cut the surface of a workpiece with the help of a CNC machine tool to obtain a flat machined surface. Under the precise control of the CNC system, the milling cutter moves along a preset program path. Through the high – speed rotation of the cutter and the feed motion, excess material is removed from the workpiece, enabling the workpiece to meet the required dimensional accuracy and surface quality requirements. Compared with traditional milling, CNC face milling can achieve automated and high – precision processing, greatly improving production efficiency and the stability of processing quality.

II. Key Points of CNC Face Milling Technology

Tool Selection

According to the workpiece material, processing accuracy, and efficiency requirements, rationally select the type of milling cutter, such as insert – type end – milling cutters, solid carbide milling cutters, etc. Parameters such as the diameter, number of teeth, and edge geometry of the cutter also affect the processing effect. For example, large – diameter milling cutters are suitable for large – area milling, and cutters with more teeth can improve surface finish.

Cutting Parameter Setting

This includes cutting speed, feed rate, and cutting depth. The cutting speed directly affects tool wear and processing efficiency, and different materials have different optimal cutting speeds. The feed rate determines the distance the cutter moves on the workpiece per unit time and needs to be adjusted according to the tool’s load – bearing capacity and the surface quality requirements of the processing. The cutting depth is determined according to the workpiece’s machining allowance and tool performance. Generally, the cutting depth is larger during rough machining and smaller during finish machining.

Programming and Path Planning

Use CAD/CAM software for programming and precisely design the tool path. A reasonable path planning can reduce idle – travel time, avoid tool collisions, and improve processing efficiency and quality. For example, using a helical plunge – cutting method can reduce the impact when the tool enters the workpiece and reduce the risk of chipping.

III. CNC Face Milling Processing Flow

Workpiece Clamping

Fix the workpiece on the worktable of the CNC milling machine using appropriate fixtures, ensuring accurate positioning and firm clamping of the workpiece to prevent workpiece displacement during processing from affecting processing accuracy.

Tool Installation

Install the selected milling cutter onto the spindle according to the processing process requirements and perform tool – setting operations to determine the relative position between the tool and the workpiece, ensuring the accuracy of processing dimensions.

Programming and Program Input

Write the processing program through programming software. The program contains information such as tool paths, cutting parameters, and spindle speed. Then transfer the program to the control system of the CNC machine tool.

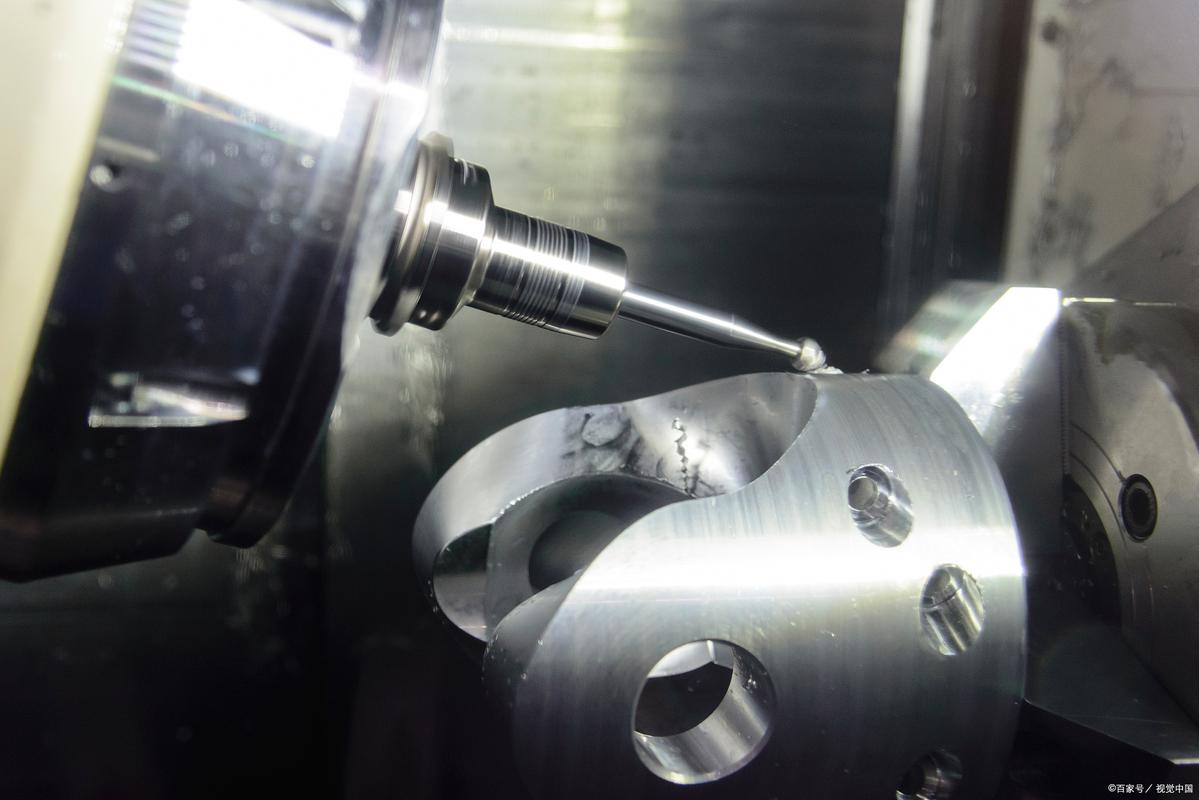

Processing Process

Start the machine tool. The CNC system controls the movement of the tool and cutting parameters according to the program instructions and performs face – milling processing on the workpiece. During the processing, the operator needs to monitor the processing status in real – time and stop the machine in time if any abnormalities are found.

Quality Inspection

After processing, use measuring tools such as micrometers, calipers, and roughness testers to detect the dimensional accuracy and surface roughness of the workpiece to ensure that the workpiece meets the design requirements. If it is unqualified, analyze the reasons and perform corrective processing.

IV. Processable Materials for CNC Face Milling

Metallic Materials

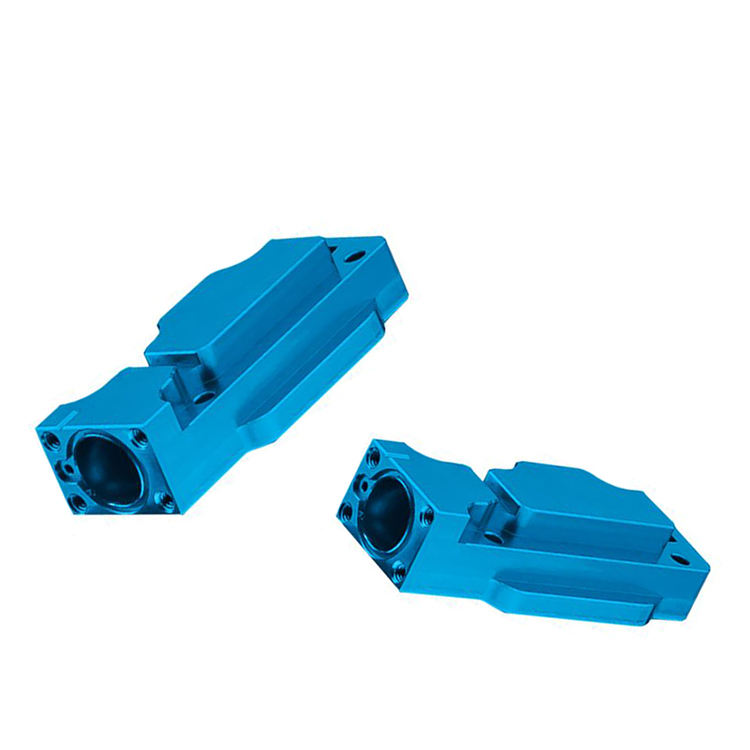

This includes aluminum alloys, stainless steels, carbon steels, alloy steels, copper alloys, etc. Aluminum alloys are widely used in the aerospace and automotive manufacturing industries due to their low density, high strength, and easy processing. CNC face milling can machine high – precision aluminum alloy part surfaces. Stainless steel is commonly used in the processing of parts for medical devices and food processing equipment because of its good corrosion resistance and strength.

Non – metallic Materials

Such as engineering plastics (nylon, polycarbonate, etc.), composite materials (carbon – fiber – reinforced composites, glass – fiber – reinforced composites), wood, etc. Engineering plastics are often used to manufacture electronic device housings and mechanical parts. CNC face milling can ensure their surface accuracy and appearance quality. Carbon – fiber – reinforced composites are widely used in the aerospace and sports goods industries, and face – milling processing can obtain surfaces that meet design requirements.

V. CNC Face – Milled Parts

Flat – type Parts

Such as various flat plates, pads, and worktable surfaces in machining. The main processing surface of these parts is a plane. CNC face milling can quickly remove material and obtain a flat surface to meet the assembly and use requirements of the parts.

Disc – type Parts

Like flanges, gear blanks, etc. The end – faces of disc – type parts usually need to be face – milled to ensure the flatness and surface roughness of the end – face, laying the foundation for subsequent hole – processing and tooth – shape processing procedures.

Plane Processing of Box – type Parts

For example, machine tool boxes, engine blocks, etc. Multiple planes of box – type parts need high – precision processing. CNC face milling can effectively ensure the positional accuracy and surface quality between each plane, ensuring the overall performance of the box – type parts.

VI. Application Fields of CNC Face Milling

Aerospace Field

It is used for processing aircraft fuselage structural parts, engine components, etc. Aerospace parts have extremely high requirements for accuracy and surface quality. CNC face milling can meet these stringent requirements, ensuring the lightweight and high – strength of parts, and improving the performance and reliability of aircraft.

Automotive Manufacturing Field

It plays an important role in the processing of automotive engine blocks, transmission cases, chassis parts, etc. Through CNC face milling, high – volume and high – precision production of automotive parts can be achieved, improving production efficiency and reducing production costs.

Mold Manufacturing Field

The parting surfaces and cavity surfaces of molds need high – precision processing. CNC face milling can ensure the flatness and finish of the mold surface, improving the service life of the mold and the quality of the molded products.

Electronic Equipment Manufacturing Field

It is used for processing parts such as electronic device housings and heat sinks, ensuring the dimensional accuracy and appearance quality of parts to meet the development needs of miniaturization and precision of electronic equipment.

VII. Technical Description of CNC Face Milling

CNC face – milling technology is an indispensable and important means in modern machining. It combines computer technology, numerical control technology, and machining technology, featuring high precision, high efficiency, and a high degree of automation. By rationally selecting tools and cutting parameters and optimizing programming and path planning, CNC face milling can perform well in the processing of different materials and parts. With the continuous development of the manufacturing industry, the requirements for processing accuracy and efficiency are getting higher and higher. CNC face – milling technology is also constantly innovating and developing. For example, the application of new technologies such as high – speed milling and five – axis – face milling has further expanded the processing capabilities and application scope of CNC face milling, providing strong support for the upgrading and development of the manufacturing industry.

The above comprehensively introduces the relevant knowledge of CNC face milling. If you want to have an in – depth understanding of a certain part or have other supplementary needs, please feel free to let me know at any time.