In the highly competitive precision field of modern manufacturing, CNC bronze parts firmly hold the spotlight as key components in numerous industries, thanks to their excellent performance and wide applicability. From the sophisticated aerospace precision instruments to the core components of life – saving medical devices, CNC bronze parts, with their high – precision and customization capabilities, have provided reliable solutions for complex engineering requirements. Next, let’s comprehensively explore the custom CNC bronze parts service!

I. Introduction to CNC Bronze Parts

What exactly are CNC bronze parts? Simply put, they are parts made by processing bronze materials using Computer Numerical Control (CNC) technology. Bronze is not just pure copper but an alloy composed of copper and elements such as tin, lead, and aluminum, boasting outstanding wear resistance, corrosion resistance, thermal conductivity, and mechanical properties. With CNC processing technology, regardless of how complex the shape or how high the precision requirement is, the bronze material can be precisely shaped into the “backbone” components of key equipment in different industries.

II. Technologies for Processing CNC Bronze Parts

CNC processing technology is the “soul” behind the high – precision customization of CNC bronze parts. It controls the movement trajectory of the machine tool’s cutting tool and processing parameters through computer programming, enabling automated and high – precision cutting. When processing CNC bronze parts, common technologies such as turning, milling, drilling, and grinding each have their unique advantages. Turning is specialized in processing rotary parts, excelling in the machining of shaft – type and sleeve – type parts; milling can handle various structures such as planes, grooves, and complex curved surfaces; drilling is responsible for processing hole features; and grinding can further improve the surface precision and finish of the parts. With the continuous evolution of technology, special processing technologies such as electrical discharge machining and laser processing have also joined the fray, easily resolving complex structures and special requirements that were previously difficult to handle with traditional processing.

III. Customization Process of CNC Bronze Parts

Requirement Communication: First, we need to have a thorough discussion with the customization service team, clearly stating all the information about the parts, including their purpose, performance requirements, dimensional specifications, surface quality, etc. If there are design drawings or conceptual sketches, they should be provided promptly, so that the team can accurately understand the requirements.

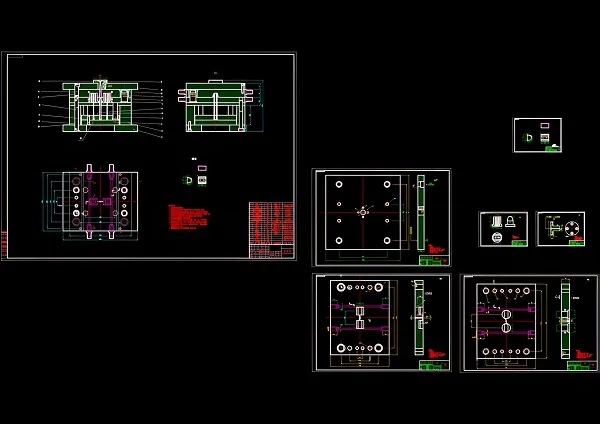

Scheme Design: After receiving the requirements, the technical team uses professional CAD/CAM software to design the parts, plan the process, and come up with a preliminary processing plan. They will also confirm with us repeatedly to ensure that the plan meets our expectations.

Material Selection: Based on the operating environment and performance requirements of the parts, the appropriate bronze alloy material is carefully selected. The quality must comply with relevant standards without any compromise.

Processing and Manufacturing: The designed program is input into the CNC machine tool, and the machine starts working diligently, processing according to the predetermined process parameters. During the processing, the quality is closely monitored to ensure that the part precision remains intact.

Quality Inspection: High – end inspection equipment such as coordinate measuring machines and roughness testers are used to conduct a comprehensive inspection of the processed parts, leaving no aspect of dimensional accuracy, geometric tolerance, and surface quality unexamined. Only parts that meet all the standards are considered qualified.

Post – processing and Delivery: If there are surface treatment requirements such as polishing, electroplating, or passivation, these operations are carried out to enhance the appearance and performance of the parts. Finally, the qualified parts are carefully packaged and delivered to us safely.

IV. Characteristics of CNC Bronze Parts

Excellent Wear Resistance: Bronze itself has remarkable wear resistance. After being processed into parts by CNC, it can remain stable in high – friction environments, significantly extending the service life of the equipment.

Good Corrosion Resistance: Bronze alloys have a certain resistance to various chemical media. Harsh environments such as humidity, acid, and alkali are no match for them, ensuring the long – term stable operation of the parts.

Outstanding Thermal Conductivity: It has an extremely fast heat – conduction speed, capable of quickly dissipating heat, effectively preventing the parts from malfunctioning due to overheating, especially suitable for components that require heat dissipation.

High Precision and Consistency: CNC processing technology is like a magic pen, precisely controlling the part precision. The dimensional tolerances are strictly controlled, and parts in the same batch are almost identical, boasting excellent precision and consistency.

Complex Structure Processing Ability: No matter how complex the geometric shape or how peculiar the internal structure is, CNC processing can handle it all, easily meeting special design requirements.

V. Applicable Fields of CNC Bronze Parts

Aerospace Field: In the high – tech aerospace field, CNC bronze parts are used to manufacture engine components, hydraulic system parts, instrument casings, etc. These parts require high strength, high precision, and the ability to withstand high temperatures, which CNC bronze parts can fully meet.

Medical Device Field: CNC bronze parts can be found in surgical instruments, transmission parts of medical equipment, etc. Here, the parts need to meet biocompatibility requirements, have high precision, and be sterile. CNC bronze parts, with their own advantages, become a reliable choice.

Automobile Manufacturing Field: Many parts in automobile engines, such as bearing shells, bushings, and various transmission parts, are CNC bronze parts. The operation of automobiles has high requirements for the wear resistance and mechanical properties of parts, which CNC bronze parts are well – suited for.

Electronics and Electrical Appliance Field: Taking advantage of the electrical and thermal conductivity of bronze, CNC bronze parts are used to manufacture parts such as connectors and heat sinks, ensuring the stable operation of electronics and electrical appliances.

Machinery Manufacturing Field: CNC bronze parts are widely used in key components of various mechanical equipment, such as gears, worm gears, and guide rails, ensuring the stable operation of the equipment and serving as a “capable assistant” in machinery manufacturing.

VI. Advantages of CNC Bronze Parts

High – degree Customization: No matter how unique your requirements are, whether it’s the shape, size, or performance of the bronze parts, they can be customized according to your needs, perfectly adapting to the special requirements of different industries and application scenarios.

High – precision Machining: The parts processed by CNC technology have excellent dimensional accuracy and surface quality, which can greatly improve the assembly accuracy and overall performance of the equipment.

High Production Efficiency: Automated processing reduces human intervention, significantly shortening the processing cycle. Even for large – quantity or urgent orders, quick delivery can be achieved.

Controllable Cost: By optimizing the process and selecting materials reasonably, the cost is well – controlled while ensuring quality, providing you with a cost – effective solution.

Stable and Reliable Quality: A strict quality inspection process, combined with advanced inspection equipment, carefully checks each part. The quality is fully reliable, greatly reducing the product failure rate.

VII. Difficulties in Processing CNC Bronze Parts

Influence of Material Characteristics: Bronze materials have high hardness, causing rapid tool wear during processing. It’s like a “battle” between the material and the tool. Careful selection of tool materials and adjustment of cutting parameters are necessary to ensure processing efficiency and tool life. Moreover, some bronze alloys are highly viscous and prone to built – up edge formation, affecting the surface quality of the parts, which is quite challenging to deal with.

High Difficulty in Processing Complex Structures: When dealing with parts with complex curved surfaces, deep holes, or thin – walled structures, various problems are likely to occur during processing, such as deformation and vibration. Precise control of the processing technology and tool path is essential to ensure part precision, which is extremely difficult.

High Requirements for Dimensional Precision Control: Some high – precision CNC bronze parts have extremely strict requirements for dimensional tolerances and geometric tolerances. The slightest error may affect the part performance. During processing, parameters need to be continuously adjusted and optimized, and high – precision inspection equipment is required for real – time monitoring. One misstep can lead to failure.

VIII. Common Problems in Processing CNC Bronze Parts

Dimensional Deviation: Programming errors, tool wear, or a decline in machine tool accuracy can all lead to incorrect part dimensions. What to do? Carefully check the program before processing, regularly replace tools, and maintain and calibrate the machine tool to effectively avoid this problem.

Poor Surface Quality: Problems such as unqualified surface roughness, scratches, and burrs mostly relate to cutting parameters, tool quality, and processing technology. Adjusting the cutting speed and feed rate, choosing the right tool, and optimizing the processing technology can improve the surface quality of the parts.

Part Deformation: Thin – walled parts and slender shaft – type parts are prone to deformation during processing due to cutting force, clamping force, and thermal deformation. Using a reasonable clamping method, optimizing cutting parameters, and performing aging treatment can reduce deformation and keep the parts in “perfect shape”.

Still worried about finding a reliable CNC bronze parts customization service? Don’t hesitate! We have advanced CNC processing equipment and a professional technical team. We offer a one – stop service from design, processing to inspection! Whether it’s super – complex aerospace parts or ultra – precise medical device components, we can handle them easily! Leave a message for consultation now, and we will immediately provide you with a customized solution and also offer free technical consultation services! Act quickly. Let’s work together to create high – quality bronze parts and boost your project!