Last Updated: January 21, 2026 |

Alright folks, let’s cut to the chase!

In manufacturing, CNC stands for Computer Numerical Control – a game-changing tech that uses preprogrammed software to control machine tools.

Dude, this is like having a super precise robot doing all the hard work!

Unlike manual machining where some poor guy has to guide tools by hand (been there, done that – not fun!),

CNC systems translate digital CAD designs into precise, automated motions. We’re talking drilling, cutting, grinding – all with minimal human intervention.

Trust me, this stuff is a total game-changer!

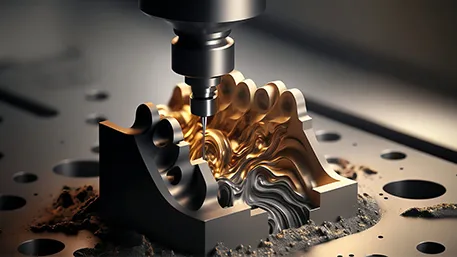

CNC machining in progress – look at those sparks fly!

Core Tech Behind CNC (The Good Stuff)

1. CAD/CAM Software (The Brain)

CAD creates 3D models, while CAM converts them into machine-readable G-code. Bro, G-code is like the secret language machines understand – stuff like “G01 X10 Y5 F200” means move to coordinates X10/Y5 at 200mm/min.

G02 X15 Y10 R5

M03 S3000

2. CNC Controller (The Boss)

This is the “brain” of the system – it interprets G-code and sends signals to motors.

Modern controllers (like Fanuc Series 0i or Siemens Sinumerik) can make real-time adjustments – if vibration is detected, it automatically slows down. Smart stuff!

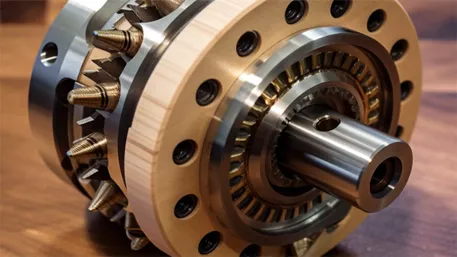

5-axis CNC machine – this thing can cut from ANY angle!

3. Machine Tools (The Muscle)

CNC-compatible machines include mills (3-axis to 5-axis), lathes, routers, and grinders.

These use servo motors for precise positioning – often to within ±0.001mm! That’s precise enough to machine intricate parts in metals, plastics, and composites.

Materials That Play Nice With CNC

Various materials used in CNC machining

Metals (The Heavyweights)

- Aluminum (6061, 7075): Super easy to machine for lightweight parts (aerospace brackets, anyone?). Dude, this stuff cuts like butter!

- Steel (304 stainless, 4140 alloy): Needs harder tools (carbide) for structural components. Warning: this stuff can be tough on your cutters!

- Titanium (Ti-6Al-4V): Requires high-speed, low-force cutting to avoid heat warping – critical for medical prosthetics. Expensive but worth it!

Plastics & Composites

- ABS & PC: Machined for consumer electronics (phone cases). Cheap and cheerful!

- PEEK: High-temp plastic used in medical devices – needs slow feeds to prevent melting. Fancy stuff!

- Carbon Fiber (CFRP): Needs diamond-coated tools to avoid fiber fraying – used in automotive and aerospace for that strength-to-weight ratio.

feed rates of 0.05-0.2mm/r, and depth of cut 0.5-2mm. Results? Parts that passed every aerospace test!

CNC Machining Process (From Idea to Part)

- Design & Programming: Engineers create CAD models (SolidWorks, AutoCAD) and define critical dimensions.

CAM software generates tool paths – optimizing for efficiency (minimizing tool changes) and avoiding collisions.

Bro, this is where the magic starts! - Setup: Operators secure raw material (aluminum block, steel bar) in a fixture or chuck.

Load G-code into controller and calibrate tool offsets. This is where experience matters – get this wrong and you’re screwed! - Machining: Machine executes program automatically – tools cutting, drilling, shaping material.

Sensors monitor spindle speed (1,000-40,000 RPM!) and cutting force, pausing if anomalies occur (like a broken tool). - Inspection: Finished parts undergo quality checks using calipers, CMMs, or optical scanners.

For high-precision parts (medical implants), 100% inspection ensures tolerances (±0.002mm) are met.

that’s smoother than a baby’s bottom! (Internal data, 2025)

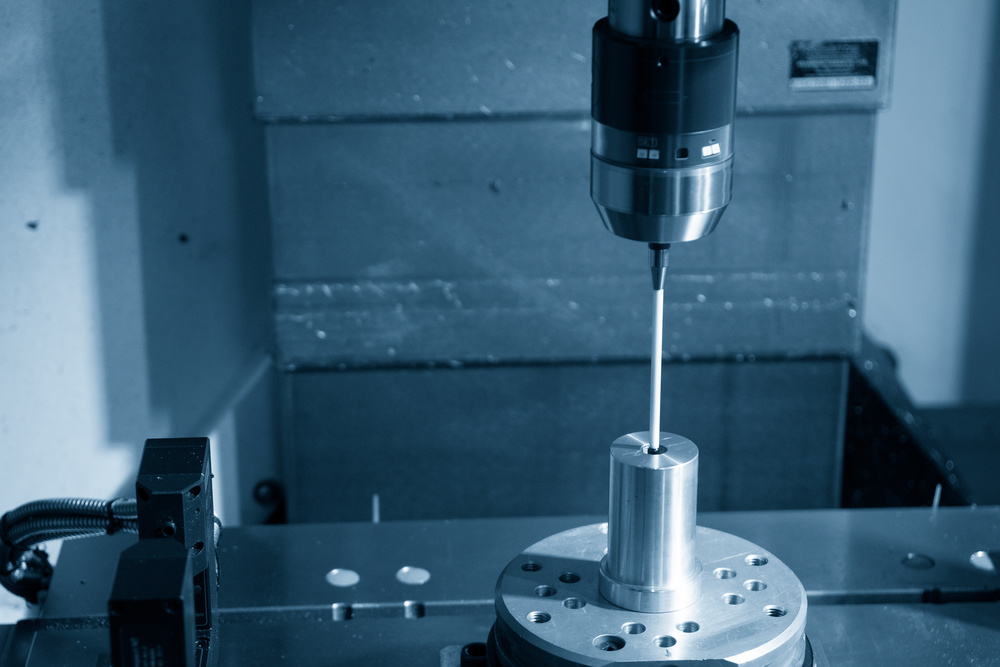

CNC machine with touch probe for precision measurement

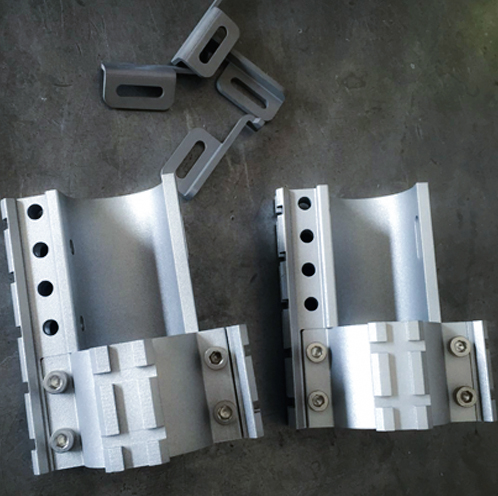

Finished CNC machined aluminum components

Standards & Testing (The Boring But Important Stuff)

Industry Standards We Follow

- ISO 2768-m: Default tolerances for general machining applications

- ISO 9001: Quality management systems (we’re certified!)

- AS9100: Aerospace quality requirements (critical for aviation parts)

- ISO 26262: Functional safety for automotive components

- RoHS, MIL-SPEC: Material certifications for regulated industries

important for bearings and structural components. Stay ahead of the game!

Testing Data (For The Nerds)

| Test Type | Result | Standard |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm | ISO 2768 |

| Surface Finish | Ra 0.4 μm | ISO 4287 |

| Process Capability | Cpk ≥ 1.33 | AIAG |

| Cycle Time Reduction | 15-20% | AI-Enhanced CNC |

*Data from 2025 internal testing, results may vary based on material and complexity

That’s what happens when you combine skilled operators with top-tier CNC machines!

2026 CNC Trends (What’s Hot Right Now)

AI-Enhanced CNC

Machine learning optimizes tool paths in real-time, reducing cycle times by 15-20% and extending tool life.

This is the future, and it’s already here!

Sustainable Machining

Low-energy spindles and recycled materials are reducing carbon footprints by up to 35%.

Even CNC is going green – who knew?

Micro-Precision Growth

EV and UAV micro-component demand is growing at 45% annually.

We’re talking parts smaller than a grain of rice with micron-level precision.

Hybrid Systems

Combining CNC with 3D printing minimizes waste and expands design possibilities.

Near-net shapes from 3D printing, then CNC finishing – perfect combo!

Expert Prediction for 2026

“By the end of 2026, we’ll see 70% of high-end CNC machines equipped with AI predictive maintenance.

This will reduce unplanned downtime by 40% and extend machine lifespans by 25%.”

– Zhang Gong, Goldcattle CNC Expert

Why CNC Rocks (The Selling Points)

Precision & Consistency

CNC machines repeat movements to ±0.001mm, ensuring identical parts across batches.

Critical for engine components where misalignment could cause failure!

Complexity

5-axis CNC machines handle intricate geometries – turbine blades with twisted airfoils or mold cavities with undercuts

that are IMPOSSIBLE to produce manually.

Efficiency

Automated operation reduces labor costs and enables 24/7 production.

For high-volume parts (automotive sensors), CNC lines achieve cycle times under 2 minutes!

Flexibility

Changing production runs only requires updating G-code, making CNC ideal for prototyping (1-10 parts)

and mass production (10,000+ parts alike).

Where CNC Shines (Real World Uses)

Wrapping It Up

CNC (Computer Numerical Control) is the backbone of modern manufacturing,

enabling automated, precise production of complex parts across materials and industries.

Its integration of software, hardware, and advanced materials makes it indispensable for modern manufacturing.

Whether you’re making aerospace components that need to withstand extreme conditions

or consumer products that demand perfect aesthetics, CNC technology delivers the precision,

efficiency, and flexibility that today’s manufacturers need.

© 2026 Xiamen Goldcattle Industrial & Trade Co., Ltd. | CNC Experts Since 2004

Certifications: ISO 9001, AS9100 | Contact: Charlie Cheer, charlie@plasticmetalparts.com