Ordering custom CNC machined parts involves a systematic integration of technical specifications, manufacturing capabilities, and supply chain management. From initial design submission to final delivery, each stage requires precise communication and engineering oversight to ensure part conformity and production efficiency. This article outlines the critical aspects of the ordering process, emphasizing technical considerations and industry best practices.

1. Order Initiation and Requirement Analysis

The foundation of successful custom CNC machining orders lies in clear requirement documentation. Engineering drawings must include geometric dimensioning and tolerancing (GD&T) per ASME Y14.5-2018 standards, with 98% of production delays attributed to incomplete or ambiguous drawings.

Key elements to specify:

- Material grade (e.g., 6061 aluminum, 316 stainless steel) with certification requirements (Mill Test Reports)

- Critical tolerances (±0.001 mm for aerospace vs. ±0.01 mm for general industrial)

- Surface finish specifications (Ra values, coating types)

- Quantity breakdown (prototyping vs. production runs)

- Acceptance criteria (inspection methods, sampling plans)

Manufacturers typically require 24-48 hours for initial feasibility assessment, with 75% of quotes delivered within 3 business days for standard components. Complex geometries with 5+ axes of machining may extend this timeline to 5-7 days.

2. Material Selection and Sourcing

Material selection directly impacts machining parameters and final part performance. Suppliers maintain inventory of 80+ common alloys, with 6061 aluminum (45%), 304 stainless steel (25%), and brass C36000 (15%) accounting for the majority of CNC orders.

Lead times for materials:

- Specialized materials (titanium Grade 5, Inconel 718): 2-4 weeks

- Custom material certifications: add 3-5 business days

Cost differentials between material forms:

- Bar stock: base price (indexed to LME or COMEX rates)

- Plate material: +15-20% due to larger cross-section

- Pre-cut blanks: +10% but reduce machining waste by 30%

Material traceability documentation is mandatory for 92% of aerospace and medical orders, requiring batch-specific certificates of compliance.

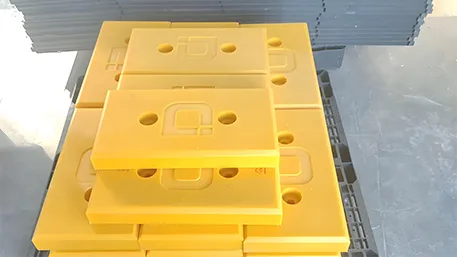

3. CNC Process Selection and Capability Matching

Matching part requirements to appropriate CNC processes optimizes production efficiency:

3-axis CNC milling suits prismatic parts with linear features, achieving feed rates up to 5000 mm/min for aluminum. It accounts for 65% of custom machining orders due to its versatility and cost-effectiveness.

4-axis machining adds rotational capability for parts like cams and levers, increasing production time by 20-30% compared to 3-axis but eliminating secondary operations.

5-axis systems handle complex geometries (e.g., impellers, aerospace fittings) with positional accuracy of ±0.003 mm, but at a 40-60% premium over 3-axis machining.

Turning centers with live tooling perform 70% of cylindrical part production, with cycle times 30% faster than mill-turn combinations for simple shafts and bushings.

Manufacturers maintain machine utilization rates of 70-85%, with 5-axis machines operating at 65-70% due to programming complexity.

4. Design for Manufacturability (DFM) Review

DFM analysis reduces production costs by 15-40% through design optimization. Critical recommendations include:

- Minimum wall thickness: 0.8 mm for aluminum, 1.2 mm for steel (prevents chatter and tool deflection)

- Internal corner radii: ≥0.5× tool diameter (reduces 70% of tool breakages)

- Hole diameters: ≥3× depth-to-diameter ratio for standard drilling; deeper holes require gun drilling (+25% cost)

- Undercut limitations: ≤2× tool diameter without special fixtures

90% of manufacturers offer complimentary DFM reviews for orders exceeding $500, with detailed reports highlighting cost-saving opportunities. Implementing DFM suggestions reduces first-article rejection rates from 22% to 5% in production runs.

5. Production Scheduling and Lead Time Management

Production timelines vary based on complexity and quantity:

- Prototyping (1-10 pieces): 3-7 business days

- Small production (10-500 pieces): 7-14 days

- Medium production (500-5000 pieces): 14-21 days

- Large production (5000+ pieces): 21-45 days

Rush orders (30-50% premium) can compress timelines by 30-50% but require:

- Priority material sourcing

- Dedicated machine time (15-20% capacity reserved for rush jobs)

- Expedited inspection processes

Supply chain disruptions affect 12% of orders annually, with average delays of 4-6 days. Reputable manufacturers maintain 2-3 alternative material suppliers to mitigate this risk.

6. Quality Assurance and Inspection Protocols

Quality control protocols scale with part criticality:

- Basic inspection: Visual checks + caliper measurements (±0.01 mm accuracy) for 100% of parts

- Medium inspection: CMM sampling (10% AQL) for dimensions, surface finish testing

- Critical inspection: 100% CMM verification, material certification audit, destructive testing (for load-bearing components)

Inspection costs typically represent 3-8% of total order value, increasing to 10-15% for aerospace and medical applications requiring PPAP (Production Part Approval Process) documentation.

First Article Inspection (FAI) is mandatory for 85% of automotive orders, with AS9102 forms required for aerospace components, adding 3-5 days to production schedules.

7. Packaging, Delivery, and Post-Delivery Support

Protective packaging prevents in-transit damage, with 99.5% of parts arriving undamaged when using:

- Anti-static bags for electronic components

- VCI (Volatile Corrosion Inhibitor) packaging for ferrous metals (720-hour protection)

- Custom foam inserts for precision parts (±0.005 mm tolerance)

Shipping methods and transit times:

- Domestic (US): 1-3 days (ground), 1-2 days (air)

- International: 3-5 days (express), 10-14 days (standard)

Post-delivery support includes:

- 30-day warranty on manufacturing defects

- Rework services for non-conforming parts (average 5-7 day turnaround)

- Material certification retention (7+ years for aerospace, per AS9100)

Frequently Asked Questions

Q: What file formats are acceptable for CNC machining orders?

A: Preferred formats include STEP (.stp), IGES (.iges), and SOLIDWORKS (.sldprt) for 3D models, with PDF or DWG for 2D drawings. 90% of manufacturers reject raster images (JPEG, PNG) due to scaling inaccuracies.

Q: How do quantity changes affect per-unit pricing?

A: Typical price breaks occur at 10, 50, 100, 500, and 1000 units. A 1000-piece order for a simple aluminum bracket reduces per-unit cost by 60% compared to a 10-piece order, primarily due to spread setup costs.

Q: Can I request a sample before full production?

A: Yes, 95% of manufacturers offer first-article samples. Prototyping costs 2-3× production units but reduce design risk. Sample lead times average 5-7 days, with 30% of projects requiring 1-2 revision cycles.

If you’re navigating the process of ordering custom CNC machined parts and have specific questions about material availability, tolerance capabilities, or production timelines, please share your requirements in the comments. Our technical team can provide tailored guidance to optimize your ordering process.