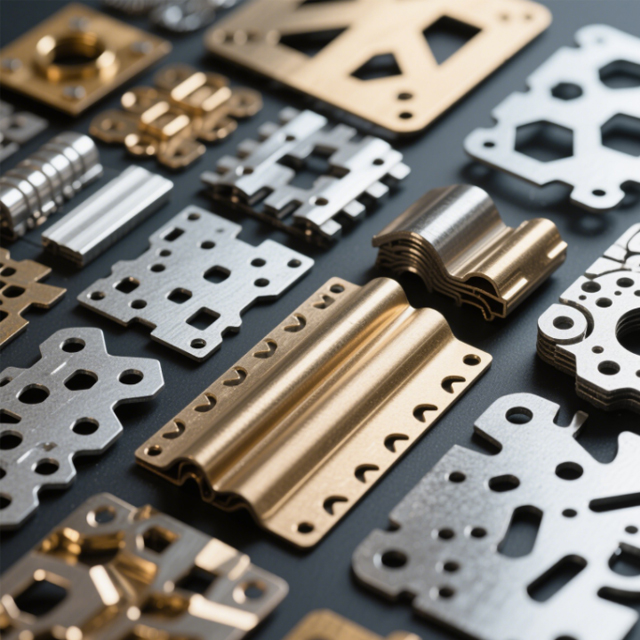

Laser Cutting Stainless Steel Sheet Metal Stamping Parts Laser Cutting Metal Parts

Material: 304/316 Stainless Steel (Food/Industrial Grade)

Processes: Laser Cutting (±0.1mm) & Metal Stamping

Thickness Range: 0.3-10mm Sheet Metal

Tolerance: ±0.1mm (Cutting); ±0.05mm (Stamping)

Applications: Automotive, Electronics, Machinery, Medical

Description

Introducing our premium laser cutting and stainless steel sheet metal stamping parts—your reliable solution for high-precision metal components. Engineered for durability and accuracy, these parts meet the strictest industrial standards.

Our materials speak for themselves: we use top-grade 304 and 316 stainless steel, chosen for their exceptional corrosion resistance, high tensile strength, and heat tolerance. 304 stainless steel offers excellent formability for general applications, while 316 adds enhanced resistance to chemicals and saltwater—ideal for harsh environments. Both are food-safe and compliant with international material standards, ensuring suitability for diverse industries.

Precision defines our craftsmanship. Our laser cutting technology delivers unmatched accuracy with ±0.1mm tolerance, effortlessly handling intricate designs, complex shapes, and fine details. The high-powered laser ensures clean, burr-free edges without material distortion. Complementing this, our metal stamping process shapes sheet metal with pinpoint precision (±0.05mm tolerance), creating consistent, repeatable parts even for large production runs. Every cut and stamp maintains material integrity, preserving the stainless steel’s inherent strength.

Our production process guarantees quality from start to finish. Begin with your CAD design or sample—our engineering team reviews it for manufacturability, optimizing for efficiency. Next, laser cutting transforms the stainless steel sheet into precise blanks, guided by advanced CNC programming. Stamping follows, using custom dies to shape the metal into final forms, with in-process checks for dimensional accuracy. Post-processing includes deburring, surface polishing, and optional treatments (passivation, coating) for enhanced durability. Final inspection uses 3D measuring tools to ensure every part meets your specifications.

These versatile parts excel across industries. In automotive manufacturing, they serve as precision brackets and connectors. Electronics rely on them for chassis components and heat sinks. Machinery uses them for gears and structural parts, while medical equipment benefits from their corrosion resistance in instrument housings. Their combination of strength and precision makes them indispensable for any application demanding reliability.

What sets our parts apart? Uncompromising quality, customizability, and on-time delivery. Whether you need prototypes or bulk production, we scale seamlessly to your needs. Our team works closely with you to refine designs, ensuring cost-effectiveness without sacrificing precision.

Order now to experience industrial-grade quality you can trust. We offer 1-3 day prototyping and 7-15 day bulk production, with a 100% quality guarantee. Partner with us for your metal component needs—where precision meets reliability, and every part is built to perform.