When it comes to shaping metal, two technologies stand out for their speed, versatility, and precision: laser cutting and plasma cutting. Both transform raw metal sheets into functional parts, but each excels in specific scenarios—from delicate electronics components to heavy-duty industrial plates. At Goldcattle, with 26 years of metal fabrication expertise, we master both techniques to deliver tailored solutions for clients across industries. Let’s break down how these technologies work, their key differences, and when to choose each—plus how Goldcattle ensures optimal results for your project.

1.Precision & Accuracy: Laser’s Microscopic Edge

Laser cutting uses a focused beam of coherent light (typically fiber or CO₂ lasers) to melt, vaporize, or burn through metal with extraordinary precision. This pinpoint accuracy makes it ideal for projects where tight tolerances and clean edges matter most.

Tolerance Levels: Laser cutting achieves ±0.001mm accuracy on thin materials (0.5–6mm), with edge straightness within 0.02mm/m—critical for parts like electronics enclosures or medical device components .

Surface Finish: The narrow heat-affected zone (HAZ) of just 0.05–0.5mm minimizes warping, leaving edges smooth (Ra 1.6–3.2μm) without secondary finishing .

Material Versatility: Shines with thin to medium metals: stainless steel (304/316), aluminum (6061), brass, and even non-ferrous metals like copper (thanks to fiber laser technology).

At Goldcattle, our 6kW fiber laser cutter recently produced 10,000 stainless steel (0.8mm thick) sensor brackets for an automotive client, maintaining consistent hole positioning (±0.01mm) across all units—eliminating assembly issues common with less precise methods.

2.Speed & Thickness: Plasma’s Heavy-Duty Advantage

Plasma cutting uses a superheated, ionized gas (plasma arc) to melt and blow away metal, making it the workhorse for thicker materials and high-volume production.

Thickness Range: Excels with metals 6–100mm thick, handling heavy plates that would slow down lasers. For example, cutting 20mm carbon steel is 3x faster with plasma than with a laser .

Cutting Speed: On 10mm carbon steel, plasma achieves 300–500mm/min—ideal for large structural parts like industrial machinery frames or shipbuilding components.

Cost Efficiency: Lower per-unit costs for thick materials, as plasma consumes less energy than high-power lasers for heavy cuts.

Goldcattle’s precision plasma system recently cut 500 carbon steel (25mm thick) beams for a construction client, completing the order 40% faster than laser cutting would have—without sacrificing edge quality (Ra 6.3μm, suitable for welding prep).

3.Material Compatibility: Matching Technology to Metal

Choosing between laser and plasma often comes down to your material type and thickness:

Laser Cutting Shines With:

Thin metals (≤6mm): Stainless steel, aluminum, brass, copper.

Heat-sensitive materials: Avoids warping in lightweight alloys like 5052 aluminum.

Intricate designs: Fine details (0.5mm slots) and sharp corners (R ≤0.2mm) for electronics or aerospace parts .

Plasma Cutting Excels With:

Thick metals (≥6mm): Carbon steel, structural steel (A36), and thick aluminum alloys.

High-carbon or abrasive metals: Handles materials that would wear laser nozzles quickly.

Large-format parts: Sheets up to 3m x 6m for industrial or construction applications.

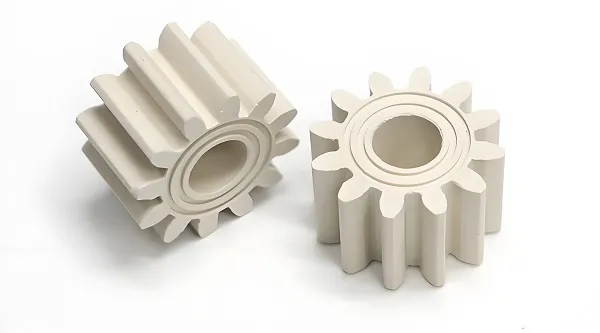

Goldcattle’s material experts help clients decide: A robotics client needed 1mm aluminum brackets with micro-grooves—we recommended laser cutting. A mining equipment manufacturer required 30mm steel plates for gear housings—plasma was the clear choice.

4.Goldcattle’s Cutting Process: Technology Tailored to Your Needs

Our end-to-end process ensures you get the right technology for your project:

Design Analysis: Our engineers review CAD files to recommend laser or plasma based on tolerance (±0.01mm vs. ±0.1mm), material thickness, and volume.

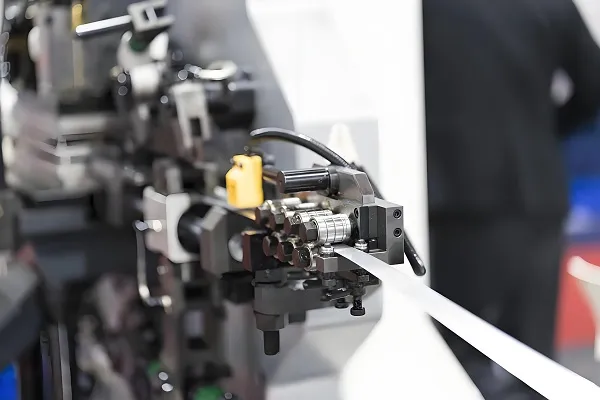

Technology Selection: For precision parts, we use 6kW–12kW fiber lasers with auto-focus heads. For heavy plates, our 120A plasma systems with CNC nesting optimize material usage.

Cutting & Quality Control: Real-time monitoring ensures consistent cut quality. Lasered parts undergo optical inspection; plasma cuts are checked for edge squareness with calipers.

Post-Processing: Optional deburring or polishing (for laser parts) and weld preparation (for plasma cuts) complete the job.

5.Applications: Where Each Technology Shines

Laser Cutting Applications:

Electronics: Circuit board enclosures, connector plates (0.5–2mm stainless).

Medical: Surgical instrument components, device chassis (Ra 1.6μm finish).

Automotive: Thin aluminum trim, sensor brackets (±0.02mm tolerance).

Plasma Cutting Applications:

Industrial Machinery: Frame components, gearbox housings (10–50mm steel).

Construction: Structural beams, support brackets (large-format plates).

Shipbuilding: Hull sections, pipe flanges (thick carbon steel).

FAQs About Laser Cutting vs Plasma Cutting

Q: Which is more cost-effective for small parts?

A: Laser cutting is often cheaper for small, intricate parts (≤6mm) due to lower material waste and fewer secondary operations. Plasma becomes cost-effective for large, thick parts (≥10mm).

Q: Can laser cut thick steel like plasma?

A: High-power lasers (15kW+) can cut up to 25mm steel, but plasma is faster and more economical for thicknesses beyond 12mm .

Q: Does plasma cutting leave rougher edges than laser?

A: Yes—plasma edges typically have Ra 6.3–12.5μm (vs. laser’s Ra 1.6–3.2μm), but Goldcattle’s precision plasma systems achieve Ra 3.2–6.3μm for weld-ready finishes.

Q: What materials can’t laser or plasma cut?

A: Lasers struggle with highly reflective materials (e.g., thick copper) without specialized fiber lasers. Plasma isn’t ideal for thin, heat-sensitive metals like titanium alloys (≤3mm).

Q: How fast can Goldcattle deliver laser vs plasma parts?

A: Laser prototypes (small batches) in 2–3 days; plasma parts (thick materials) in 3–5 days. Large production runs take 1–2 weeks for both technologies.

Ready to Choose the Right Cutting Technology?

Laser and plasma cutting each have unique strengths—your project’s success depends on matching the right technology to your material, tolerance, and volume needs. At Goldcattle, we don’t just offer cutting services—we provide tailored solutions, combining expertise in both technologies to deliver parts that meet your exact specifications.

Visit https://www.xmgoldcattle.com/ to upload your design or request a free consultation. Our team will recommend the best cutting method for your project.

Got a metal cutting project in mind? Share your material, thickness, and tolerance requirements below—we’ll help you decide between laser and plasma!