Steel cannot be effectively or practically anodized for industrial purposes. Unlike aluminum, which forms a thick, durable oxide layer via anodization, steel’s anodic oxidation produces a thin, porous, and unstable iron oxide film (rust) that offers little corrosion resistance or decorative value. Instead, steel relies on alternative treatments like galvanizing, plating, or phosphatizing for surface protection and enhancement.

Detailed Analysis of Steel Anodization Feasibility

1. Technical Principles: Why Steel Differs from Aluminum

Anodization is an electrolytic process where a metal acts as the anode in an electrolyte, forming a protective oxide layer through controlled oxidation. For aluminum, this process creates a dense, adherent aluminum oxide (Al₂O₃) layer that can be dyed, sealed, and customized for corrosion resistance or aesthetics. Steel, however, behaves very differently:

- Oxide Layer Composition: Steel’s primary component is iron, which oxidizes to form iron oxides (FeO, Fe₂O₃, Fe₃O₄) during anodization. These oxides are inherently porous, non-adherent, and prone to flaking, unlike aluminum’s compact oxide structure. Even under optimized conditions, the iron oxide layer is thin (<1μm) and offers minimal barrier protection against corrosion.

- Electrochemical Behavior: Iron has a higher oxidation potential than aluminum, meaning it corrodes more readily in aqueous electrolytes. During anodization, steel tends to undergo uncontrolled dissolution (rusting) rather than forming a uniform oxide layer. This results in uneven, powdery deposits instead of a smooth, protective film.

- Sealability Issues: Aluminum oxide layers are porous and can be sealed with hot water or chemicals to block pores, enhancing durability. Steel oxides cannot be effectively sealed; their porous structure retains moisture, accelerating further corrosion beneath the film.

2. Attempted Steel Anodization Processes & Limitations

While steel anodization is not industrially viable, experimental processes highlight its challenges:

- Acidic Electrolytes: Early attempts used sulfuric or nitric acid electrolytes (similar to aluminum anodization). However, these solutions cause rapid iron dissolution, leading to pitting and uneven oxide growth. Even at low voltages (5–10V), the oxide layer peels off within hours of exposure to moisture.

- Alkaline Electrolytes: Alkaline solutions (e.g., sodium hydroxide) reduce iron dissolution but produce even thinner oxide layers. The resulting film is soft, gray, and offers no meaningful corrosion resistance—far inferior to aluminum’s anodized finish.

- Plasma Electrolytic Oxidation (PEO): A high-voltage variant (500–1000V) tested on steel creates a thicker oxide layer via plasma discharges. While PEO forms a harder film (up to 500 HV), it remains porous and prone to cracking. This method is energy-intensive and not cost-effective compared to alternatives like galvanizing.

3. Material-Specific Challenges in Steel

Steel’s composition and microstructure further hinder anodization:

- Carbon Content: High-carbon steels (e.g., 1095) form more brittle oxide layers due to carbon segregation at grain boundaries, increasing flaking risk. Low-carbon steels (e.g., 1018) perform marginally better but still fail to produce durable films.

- Alloying Elements: Stainless steels, containing chromium (≥10.5%), form a passive chromium oxide layer naturally. Anodization disrupts this layer, causing localized corrosion (pitting) instead of uniform oxidation. Tool steels with high tungsten or vanadium content develop uneven oxides due to differential alloy oxidation rates.

- Surface Condition: Cold-rolled or polished steel surfaces show slightly more uniform oxide growth, but the layer still lacks adhesion. Rust-prone hot-rolled steel cannot form any coherent oxide during anodization, as existing rust interferes with film formation.

4. Alternatives to Anodization for Steel Surface Treatment

Industries use proven methods to protect and enhance steel surfaces, as anodization is impractical:

- Galvanizing: Coating steel with zinc via hot-dip or electroplating creates a sacrificial layer that corrodes preferentially, protecting the underlying steel. Used for structural parts (e.g., bridges, nails) and offers 5–25 years of corrosion resistance.

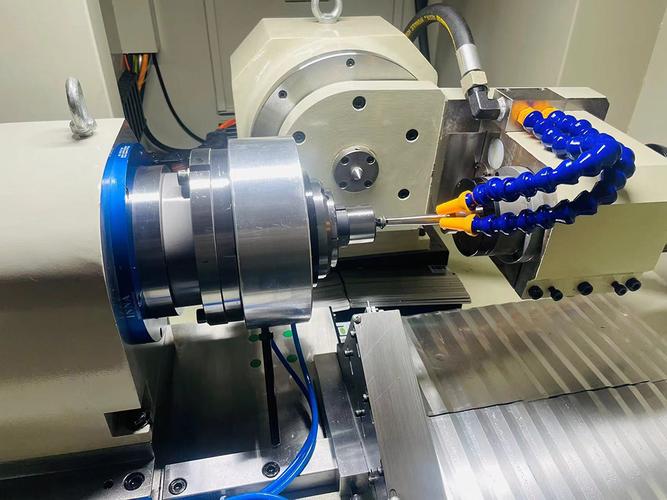

- Electroplating: Chrome, nickel, or zinc-nickel plating provides a hard, decorative, and corrosion-resistant finish. Chrome-plated steel is common in automotive trim and machinery parts, offering wear resistance (60–70 HRC) and a glossy appearance.

- Phosphatizing: Treating steel with phosphoric acid forms a porous phosphate layer that improves paint adhesion and mild corrosion resistance. Used as a pre-treatment for automotive bodies and appliance panels before painting.

- Black Oxide (Bluing): A chemical process creating a black iron oxide layer, primarily for aesthetics and mild corrosion resistance in tools, firearms, and decorative parts. Requires oil sealing to maintain protection.

- Powder Coating: Applying a dry powder (polyester, epoxy) and curing it with heat forms a thick (50–150μm), durable layer. Used for outdoor furniture, metal enclosures, and automotive parts, offering excellent UV and corrosion resistance.

5. Industrial Applications & Why Anodization Isn’t Used

Steel’s primary applications demand reliable corrosion protection and durability, making anodization unsuitable:

- Automotive Industry: Steel components (frames, panels) use galvanizing or powder coating for long-term rust resistance, as anodized layers would fail under road salt and moisture exposure.

- Construction: Structural steel relies on galvanizing or paint systems to withstand outdoor conditions. Anodization’s thin, unstable film cannot protect against rain, humidity, or mechanical wear.

- Tool Manufacturing: Tools require hard, wear-resistant surfaces. Black oxide or chrome plating is preferred over anodization, which would not enhance hardness or durability.

- Aerospace & Defense: High-strength steel parts use cadmium plating (for corrosion resistance) or phosphate conversion coatings (for paint adhesion), as anodization cannot meet strict performance standards.

6. Research & Experimental Developments

While industrial adoption is absent, research explores modified steel anodization for niche uses:

- Composite Oxide Layers: Adding inhibitors (e.g., cerium, molybdate) to electrolytes improves oxide adhesion, but results remain inferior to galvanizing.

- Hybrid Processes: Combining anodization with post-sealing (e.g., silane treatments) reduces porosity, but the cost outweighs benefits compared to existing methods.

- Nanostructured Steel: Anodizing nanostructured steel (grain size <100nm) produces slightly denser oxides, but scalability and cost hinder commercialization.

In summary, steel cannot be effectively anodized to form a durable, protective oxide layer. Its iron-based oxides lack the stability and adhesion of aluminum’s anodized film, making alternative treatments like galvanizing, plating, or powder coating the standard for steel surface enhancement across industries.