CNC brass faucet parts refer to precision-engineered components for faucets (kitchen, bathroom, or industrial) manufactured using Computer Numerical Control (CNC) machining. Unlike traditional cast or manually finished faucet parts, CNC brass components are produced via automated tools (CNC lathes, mills, drills) programmed with digital designs—ensuring tight tolerances (typically ±0.01mm to ±0.05mm), consistent performance, and long-term durability.

Brass—an alloy of copper (60–70%) and zinc (30–40%)—is the ideal material for faucet parts due to its natural corrosion resistance (critical for water contact), antimicrobial properties (supports hygiene), and excellent machinability (enables intricate designs). Common CNC brass faucet parts include valve cores, spouts, handles, water inlets/outlets, and aerators.

1. Types of CNC Brass Faucet Parts (With Design & Applications)

CNC brass faucet parts are specialized for different functional roles in a faucet system. Below is a breakdown of key components, their design features, and why CNC machining is essential:

1.1 CNC Brass Valve Cores (Cartridges)

- Design Features: Precision-machined internal chambers (for water flow control), ceramic or brass seals (to prevent leaks), and standardized stem sizes (compatible with faucet handles). Tolerances for seal surfaces are as tight as ±0.005mm to avoid dripping.

- CNC Machining Edge: Multi-axis CNC mills create complex internal flow channels (e.g., 2-way or 3-way for hot/cold mixing) with uniform wall thickness—ensuring consistent water pressure and no blockages.

- Typical Applications: Kitchen sink faucets (single-lever or double-handle), bathroom vanity faucets, shower mixers.

- Reading Key Points Tips: Valve cores are the “heart” of a faucet—prioritize CNC-machined brass (vs. plastic) for leak resistance; look for ceramic seals to extend service life (5–10 years vs. 2–3 years for rubber seals).

1.2 CNC Brass Spouts (Water Outlets)

- Design Features: Smooth internal bores (Ra 0.8–1.6μm) to minimize water turbulence, curved or straight profiles (for ergonomic use), and integrated aerator threads (M24 or G1/2 standards).

- CNC Machining Edge: CNC turning ensures concentricity of the spout (≤0.02mm runout), preventing water splashing; 5-axis machining enables curved spouts (e.g., gooseneck designs) with consistent wall thickness (1.5–2mm).

- Typical Applications: Kitchen pull-down faucets, bathroom widespread faucets, commercial restaurant faucets.

- Reading Key Points Tips: For kitchen faucets, choose CNC brass spouts with a brushed finish (hides water spots); ensure internal bores are deburred to avoid mineral buildup (common in hard water areas).

1.3 CNC Brass Handles & Knobs

- Design Features: Ergonomic shapes (e.g., cylindrical, lever-style), textured surfaces (for grip), and threaded inserts (to attach to valve stems). Decorative options include engraved patterns or polished finishes.

- CNC Machining Edge: CNC milling carves intricate designs (e.g., brand logos, geometric patterns) with uniform depth; automated polishing ensures consistent shine across batches.

- Typical Applications: Bathroom faucet knobs, vintage-style kitchen faucets, luxury hotel faucets.

- Reading Key Points Tips: Lever-style handles are easier to clean than knobs; opt for nickel-plated CNC brass handles to resist tarnishing from water and soap.

1.4 CNC Brass Water Inlets/Outlets (Connectors)

- Design Features: Standard pipe threads (NPT, BSP, or G1/2), O-ring grooves (for leak-proof sealing), and thickened walls (2–3mm) to withstand water pressure (up to 1.6 MPa).

- CNC Machining Edge: CNC tapping creates precise threads (class 2B or 3B tolerance) to avoid cross-threading; automated inspection ensures thread depth and pitch consistency.

- Typical Applications: Faucet-to-pipe connections, showerhead hoses, under-sink water filters.

- Reading Key Points Tips: For under-sink faucets, choose lead-free CNC brass connectors (compliant with drinking water standards); ensure O-ring grooves are machined to fit standard rubber or silicone O-rings.

2. Why Choose Brass for CNC Faucet Parts? Key Benefits

Brass outperforms other materials (plastic, stainless steel, zinc alloy) for faucet components, thanks to properties tailored to water-contact and hygiene needs:

2.1 Natural Corrosion Resistance

Brass forms a thin, protective oxide layer (patina) when exposed to water and air. This layer prevents rust (unlike steel) and resists degradation from chlorinated or hard water. For example:

- CNC brass valve cores last 5–10 years in hard water areas (vs. 1–2 years for plastic cores, which degrade from mineral buildup).

- Brass spouts avoid the “white rust” common in zinc alloy faucets, maintaining aesthetics long-term.

2.2 Antimicrobial Properties

Copper (a key component of brass) naturally kills 99.9% of bacteria (e.g., E. coli, Salmonella) within 24 hours—critical for faucets used for drinking water or handwashing. Studies by the EPA confirm brass surfaces reduce cross-contamination risks, making CNC brass parts ideal for kitchens, bathrooms, and healthcare facilities.

2.3 Excellent Machinability

Brass requires low cutting forces and produces minimal tool wear, enabling high-speed CNC machining:

- CNC lathes operate at 3,000–4,500 RPM for brass (vs. 2,000–3,000 RPM for stainless steel), reducing production time by 25–30%.

- Brass chips are brittle and easy to remove, preventing tool clogging (a common issue with plastic or aluminum).

2.4 Aesthetic Versatility

Brass accepts diverse surface treatments to match any design style:

- Chrome Plating: Creates a shiny, modern finish (resists scratches and water spots) for contemporary faucets.

- Nickel Plating: Offers a warm, satin finish (hides fingerprints) for bathroom vanities.

- Brushed Brass: Provides a vintage, industrial look (popular in farmhouse-style kitchens) with a textured surface.

- Antiqued Brass: Uses chemical treatments to create a aged patina (ideal for heritage or luxury faucets).

2.5 Lead-Free Options for Drinking Water Safety

Modern brass alloys (e.g., C38500, C69300) have lead content <0.25%—compliant with global drinking water standards (U.S. NSF 61, EU EN 1988-2). This eliminates the health risks of lead leaching (common in older, leaded brass faucets) while retaining brass’s durability.

- Reading Key Points Tips: Brass’s combination of corrosion resistance and antimicrobial properties is unique—no other material offers both for faucet parts. For drinking water applications, always choose lead-free CNC brass (look for NSF 61 certification).

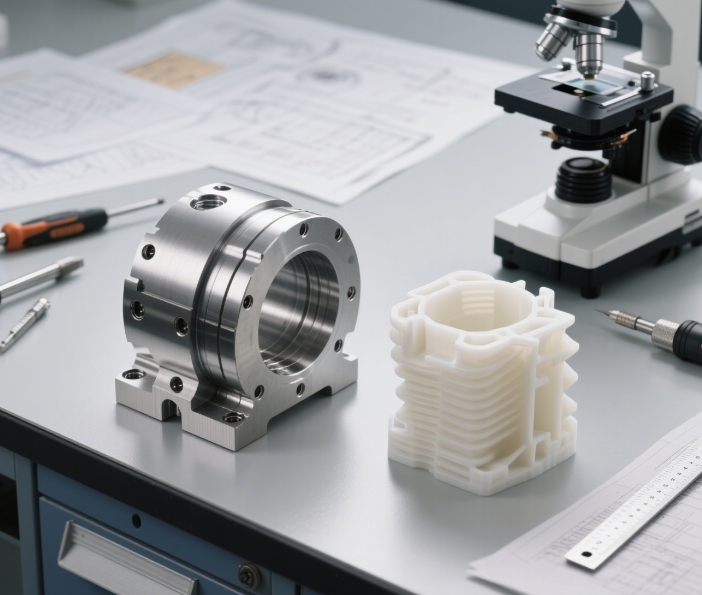

3. CNC Machining Process for Brass Faucet Parts (Step-by-Step)

The production of CNC brass faucet parts follows a strict workflow to ensure leak resistance, precision, and compliance with safety standards:

Step 1: Design & CAD Modeling

- Engineers create 3D CAD models (SolidWorks, AutoCAD) of parts, defining:

- Flow channels (for valve cores) with smooth curves to avoid pressure drops.

- Thread sizes (e.g., G1/2 for connectors) and O-ring groove dimensions (to fit standard seals).

- Tolerances: ±0.005mm for valve seal surfaces, ±0.02mm for spout concentricity.

- Designs are optimized for CNC machining (e.g., adding 0.5mm draft angles to internal chambers for easy tool access).

Step 2: Brass Alloy Selection

- Choose alloys based on safety and performance:

- C38500 (Lead-Free Brass): <0.25% lead, compliant with NSF 61—used for all water-contact parts (valves, spouts, connectors).

- C36000 (Free-Cutting Brass): 3% lead (high machinability)—used for non-water-contact parts (handles, decorative knobs) in non-drinking water applications.

- C69300 (High-Copper Brass): 85% copper, enhanced antimicrobial properties—used for healthcare or food-service faucets.

Step 3: CNC Machining

- CNC Turning: Used for cylindrical parts (spouts, connectors)—a rotating brass bar is shaped by cutting tools. Parameters: Speed = 3,500 RPM; Feed rate = 0.15 mm/rev; Depth of cut = 1–2mm.

- CNC Milling: Used for complex parts (valve cores, handles)—3-axis or 5-axis mills cut internal channels, O-ring grooves, and decorative features. For valve cores, 5-axis machining ensures flow channels are aligned with seals.

- CNC Tapping: Creates precise threads for connectors (e.g., M24 × 1.5mm) with class 2B tolerance—critical for leak-proof pipe connections.

Step 4: Surface Treatment

- Deburring: Remove sharp edges via tumbling (ceramic media) or CNC deburring tools—prevents injury and ensures O-rings seat properly.

- Plating/Cleaning:

- Chrome/nickel plating: Electroplated layers (5–10μm thick) for corrosion resistance and aesthetics.

- Passivation: For brushed brass—chemical treatment to enhance the patina layer (resists tarnishing).

- Ultrasonic cleaning: Remove oil or debris from internal channels—prevents water contamination.

Step 5: Quality Inspection

-

Dimensional Check: Use Coordinate Measuring Machines (CMM) to verify tolerances (e.g., valve seal flatness ≤0.005mm).

-

Leak Testing: Submerge parts in water and apply pressure (1.6 MPa) for 30 minutes—no bubbles indicate a leak-proof seal.

-

Material Testing: X-ray fluorescence (XRF) confirms lead content (<0.25% for NSF 61 compliance).

-

Reading Key Points Tips: Leak testing is non-negotiable for faucet parts—ask suppliers for test reports. For drinking water applications, insist on NSF 61 or FDA certification to ensure safety.

4. How to Select the Right CNC Brass Faucet Parts?

Follow this checklist to choose parts that meet safety, performance, and design needs:

4.1 Prioritize Safety & Compliance

- Lead-Free Requirement: For drinking water faucets, select parts made from C38500 or C69300 brass (lead <0.25%) with NSF 61 or EU EN 1988-2 certification.

- Antimicrobial Needs: For kitchens/bathrooms, choose high-copper brass (C69300) to reduce bacteria growth.

4.2 Evaluate Performance Features

- Leak Resistance: Check for CNC-machined O-ring grooves (uniform depth) and ceramic seals (for valve cores)—these prevent dripping.

- Water Pressure Compatibility: Ensure parts are rated for your water pressure (most residential systems: 0.3–1.0 MPa; commercial: up to 1.6 MPa).

- Durability: Look for thick-walled parts (≥1.5mm for spouts, ≥2mm for connectors) to withstand daily use and temperature changes (hot water up to 80°C).

4.3 Match Design & Aesthetics

- Surface Finish: Chrome for modern kitchens, brushed brass for vintage styles, nickel for low-maintenance bathrooms.

- Fit & Compatibility: Verify thread sizes (NPT for North America, BSP for Europe) and handle stem dimensions to match your faucet model.

4.4 Consider Cost & Supplier Reliability

-

Cost Range: CNC brass faucet parts cost $2–$20 per unit (valve cores: $5–$10; spouts: $10–$20)—higher than plastic, but 5–10x more durable.

-

Supplier Credentials: Choose ISO 9001-certified suppliers with experience in faucet parts—avoid low-cost manufacturers with no compliance documentation.

-

Reading Key Points Tips: Don’t compromise on lead-free compliance for cost—leaded brass faucets pose health risks and may violate local regulations (e.g., U.S. Safe Drinking Water Act).

5. Common Myths About CNC Brass Faucet Parts (Debunked)

5.1 Myth 1: “Brass faucet parts rust over time.”

- Fact: Brass does not rust (rust is iron oxide)—it forms a protective patina that prevents corrosion. Unplated brass may develop a greenish patina, but this is cosmetic and can be cleaned with brass polish. Plated brass (chrome/nickel) avoids patina entirely.

5.2 Myth 2: “Lead-free brass is less durable than leaded brass.”

- Fact: Modern lead-free alloys (C38500) have tensile strength (420 MPa) comparable to leaded brass (C36000: 415 MPa). They also resist dezincification (a common issue with leaded brass in hard water), extending service life by 20–30%.

5.3 Myth 3: “CNC brass parts are too expensive for residential faucets.”

- Fact: While CNC brass parts cost more upfront than plastic, they last 5–10 years (vs. 1–2 years for plastic). This reduces replacement costs—over 10 years, CNC brass parts are 30–50% cheaper than plastic alternatives.

5.4 Myth 4: “All brass faucet parts are the same—supplier choice doesn’t matter.”

-

Fact: Low-quality suppliers use impure brass (with iron or excess lead) or skip leak testing—leading to dripping faucets or lead leaching. Reputable suppliers (ISO 9001, NSF 61 certified) use high-purity brass and conduct rigorous testing.

-

Reading Key Points Tips: Always ask for material certificates and leak test reports—cheap brass parts often cut corners on safety and quality.

6. Frequently Asked Questions (FAQs)

Q1: How long do CNC brass faucet parts last?

A1: With proper maintenance, CNC brass faucet parts last 10–15 years. Valve cores (with ceramic seals) last 5–10 years; spouts and connectors can last 15+ years. Hard water may reduce lifespan slightly—regular cleaning with vinegar prevents mineral buildup.

Q2: Can I replace plastic faucet parts with CNC brass parts?

A2: Yes—most faucet models have standardized dimensions (e.g., valve stem size, thread size). Ensure the CNC brass part matches your faucet’s specifications (e.g., G1/2 threads for connectors) and weight (brass is heavier, but most faucets support the extra weight).

Q3: How to clean and maintain CNC brass faucet parts?

A3:

- Daily cleaning: Wipe with a soft cloth and mild soap—avoid abrasive cleaners (scratch plating).

- Hard water buildup: Soak parts in vinegar (50% water, 50% vinegar) for 30 minutes, then scrub with a soft brush.

- Unplated brass: Polish with a brass cleaner (e.g., Wright’s Brass Polish) every 3–6 months to maintain shine.

Q4: Are CNC brass faucet parts compatible with hot water?

A4: Yes—CNC brass parts are rated for hot water up to 80°C (common in residential water heaters). For commercial applications (e.g., restaurant dishwashers, 95°C water), choose high-temperature brass alloys (e.g., C61400) with enhanced heat resistance.

Q5: What certifications should I look for in CNC brass faucet parts?

A5:

- Drinking water safety: NSF 61 (U.S.), EN 1988-2 (EU), or FDA (global).

- Quality management: ISO 9001 (supplier quality).

- Antimicrobial claims: EPA registration (for high-copper brass parts).

Conclusion: CNC Brass Faucet Parts—Safety, Durability, and Style

CNC brass faucet parts combine brass’s natural advantages (corrosion resistance, antimicrobial properties) with CNC precision (leak-proof seals, consistent performance)—making them the gold standard for residential and commercial faucets. By prioritizing lead-free compliance, leak testing, and reputable suppliers, you can ensure your faucets are safe, long-lasting, and aesthetically pleasing.

If you have specific needs (e.g., “NSF 61-certified valve cores” or “vintage-style brushed brass handles”), share your requirements in the comments—we’ll help you connect with trusted manufacturers and optimize your faucet design!