CNC milling is one of the most widely used subtractive manufacturing technologies—but its perceived difficulty varies wildly: a hobbyist making wooden coasters might find it approachable, while an engineer machining aerospace-grade titanium parts will face steeper challenges. Below is a no-nonsense Q&A to clarify who finds it difficult, why, and how to overcome common hurdles.

Q1: The Core Question—Is CNC Milling Difficult for Beginners?

Short Answer: No, but it’s not “push-button easy” either. Most beginners can learn to make simple parts (e.g., keychains, plastic brackets) in 4–8 weeks with the right tools and guidance.

Longer Explanation:

The difficulty depends on your goals:

- If you’re a hobbyist using a desktop CNC mill (e.g., Shapeoko, X-Carve) and pre-made designs (from platforms like Thingiverse), you can master basic operation (loading files, securing material, starting cuts) in a weekend. These machines often come with simplified software (e.g., Easel for X-Carve) that skips complex G-code programming.

- If you want to design your own parts (e.g., a custom phone stand), you’ll need to learn basic CAD/CAM (e.g., Fusion 360’s “Beginner Mode”)—this adds 2–4 weeks of practice, but modern software has tutorials to walk you through it.

- The “difficulty spike” only hits if you jump straight to industrial-grade machines (e.g., Haas VF-2) or complex tasks (e.g., 5-axis milling of curved metal parts) without foundational skills.

Example: A beginner with no machining experience bought a $1,500 desktop CNC mill. After following Fusion 360’s “CNC Milling for Beginners” course (10 hours total) and practicing 3 times, they successfully made a aluminum keychain with engraved text—no major mistakes.

Q2: What Core Skills Do You Need for CNC Milling? (And Which Are “Hard”?)

CNC milling combines 3 skill areas, each with varying difficulty levels. Below is a breakdown to avoid feeling overwhelmed:

|

Skill Area

|

What It Entails

|

Difficulty for Beginners

|

Key Tip to Simplify

|

|

1. Material & Tool Setup

|

Securing workpieces (e.g., clamping wood/plastic), choosing tools (e.g., endmills), calibrating offsets.

|

Low-Medium

|

Start with soft materials (pine wood, acrylic)—they’re forgiving if you mess up clamping. Use “quick-set vises” (e.g., Wilton 4-inch) to skip complex alignment.

|

|

2. CAD/CAM Design

|

Creating 3D models (CAD) and converting them to machine code (CAM/G-code).

|

Medium

|

Use Fusion 360’s “CNC Milling Templates”—they pre-set tool paths (e.g., “pocketing” for holes) so you don’t start from scratch.

|

|

3. Machine Operation & Troubleshooting

|

Running the mill, monitoring cuts, fixing issues (e.g., tool breakage, rough surfaces).

|

Low-Medium

|

Start with “air cuts” (running the tool path without cutting material) to check for collisions—this avoids damaging tools or parts.

|

Critical Note: You don’t need to master all 3 at once. Beginners can outsource CAD design (e.g., hire a freelancer on Fiverr for (50–)100) to focus on setup and operation first.

Q3: What’s the Most Frustrating Part for Newbies? How to Fix It?

Most beginners get stuck on 2 specific issues—here’s how to solve them without quitting:

Frustration 1: “My part came out too small/big—why?”

Common Cause: Incorrect “work offset” (the machine doesn’t know where the workpiece starts). For example, if you forget to calibrate the Z-axis (height of the tool above the material), the tool will cut too deep or too shallow.

Fix:

- Use a touch probe (affordable for desktop mills—(50–)100) to auto-calibrate offsets. Probes measure the workpiece’s size and position, eliminating manual guesswork.

- Double-check the CAM software’s “material size” setting. If you tell the software your wood block is 100mm wide, but it’s actually 98mm, the cut will be off by 2mm.

Frustration 2: “My tool broke mid-cut—now what?”

Common Cause: Using the wrong tool for the material (e.g., a plastic endmill on aluminum) or too high spindle speed. For example, a 3mm HSS endmill (designed for wood) will snap if you run it at 5,000 RPM on steel.

Fix:

- Follow “tool-material speed charts” (most CNC software has built-in ones). For example:

-

- Wood: HSS endmill, 10,000–15,000 RPM

-

- Aluminum: Carbide endmill, 3,000–6,000 RPM

-

- Steel: Carbide endmill, 1,000–2,000 RPM

- Keep a spare tool set (e.g., 3-pack of 6mm carbide endmills for $30) on hand—breaking tools is normal when learning.

Q4: Has Modern Technology Made CNC Milling Easier?

Absolutely—3 key innovations have lowered the barrier for beginners and small businesses:

- Simplified CAD/CAM Software:

Tools like Fusion 360 (free for hobbyists) and VCarve Desktop have “wizard modes” that ask plain-language questions (“What material are you using?” “Do you want holes?”) and auto-generate G-code. You no longer need to learn manual G-code programming (e.g., writing lines like “G01 X10 Y5 F500”) to make parts.

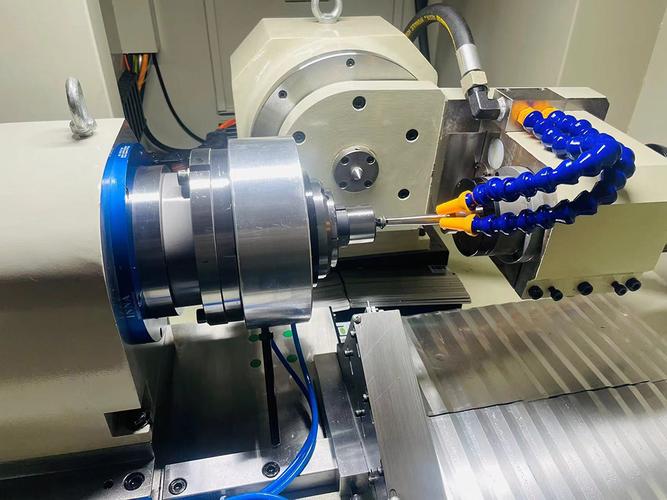

- Affordable Desktop CNC Mills:

10 years ago, a CNC mill cost (10,000+. Today, )1,000–$3,000 desktop models (e.g., Shapeoko 5, Stepcraft M.1000) are pre-assembled and come with step-by-step setup guides. They’re small enough for a garage and safe for beginners (most have emergency stop buttons).

- AI-Powered Troubleshooting:

Some industrial machines (e.g., Haas UMC-750) use AI to detect issues in real time—if the tool starts vibrating, the machine auto-adjusts the feed rate. Even desktop software like Carbide Create has “error checking” that flags mistakes (e.g., “Tool path goes outside workpiece”) before you cut.

Q5: Hobby vs. Industrial-Grade CNC Milling—Is the Difficulty Gap Big?

Yes—but the gap is about precision and complexity, not basic operation. Here’s how they compare:

|

Aspect

|

Hobby-Grade CNC Milling (e.g., Desktop Mills)

|

Industrial-Grade CNC Milling (e.g., 5-Axis Mills)

|

|

Part Tolerance

|

±0.1mm (good for coasters, toys)

|

±0.005mm (critical for aerospace parts)

|

|

Material

|

Wood, plastic, soft aluminum

|

Titanium, stainless steel, Inconel

|

|

Setup Time

|

15–30 minutes per part

|

2–4 hours (due to precision calibration)

|

|

Skill Requirement

|

CAD basics + basic machine operation

|

Advanced CAM programming + metallurgy knowledge

|

Example: A hobbyist can make a wooden chess piece in 1 hour (setup + cut). An industrial shop making a titanium aircraft bracket needs 3 hours to calibrate the machine, 2 hours to program the 5-axis tool path, and 1 hour to cut—plus post-cut inspection with a CMM (Coordinate Measuring Machine).

Q6: From “Can Operate” to “Mastered”—What’s the Hardest Step?

The biggest leap is from “making simple parts” (e.g., flat brackets) to “optimizing for efficiency and quality” (e.g., reducing cycle time, improving surface finish). Here’s why it’s tough—and how to tackle it:

- Challenge 1: Optimizing Tool Paths:

A beginner’s tool path might take 20 minutes to cut a part; a pro can trim it to 10 minutes by adjusting “stepover” (how much the tool moves side-to-side) and “plunge rate” (how fast the tool dives into material). This requires understanding how tools wear and how materials react to different cuts.

Fix: Practice with “time-study” exercises—take a simple part, program 3 different tool paths, and compare cycle time and finish quality.

- Challenge 2: Machining Hard Materials:

Cutting steel or titanium requires knowing how to use coolants (e.g., oil-based vs. water-based), adjust spindle torque, and prevent “workpiece deflection” (material bending during cutting).

Fix: Start with “soft metal” practice (e.g., 6061 aluminum) before moving to steel—aluminum behaves similarly but is more forgiving.

Final Verdict: Is CNC Milling Difficult?

It depends on your goals:

- For beginners making simple parts: No—with a desktop mill and simplified software, you can learn the basics in weeks.

- For industrial-grade precision or complex parts: Yes—but the difficulty is manageable with structured learning (e.g., online courses like CNC Chef, on-the-job training).

The key is to start small: Make a wooden coaster first, then a plastic bracket, then a soft aluminum part. Each success builds confidence—and before you know it, what felt “difficult” will feel routine.

If you’re just starting, we recommend:

- Buying a budget desktop CNC mill ((1,500–)2,500).

- Taking Fusion 360’s free “CNC Milling Fundamentals” course.

- Practicing with 1–2 simple designs (e.g., a keychain, a phone stand) before moving to complex parts.