1. Core Technical Functions of CNC Mill Enclosures

(1) Safety Protection: Compliance with International Standards

- ISO 13849-1: Ensures the enclosure’s safety-related parts (e.g., emergency stop buttons, safety interlocks) have a Performance Level (PL) of at least PLd (for medium-risk milling processes) or PLe (for high-risk processes like titanium roughing).

- EN 60204-1: Requires the enclosure’s electrical safety—insulation resistance ≥10 MΩ, grounding resistance ≤4 Ω—to prevent electric shock from exposed wires.

- Physical Isolation: Resists impact from flying chips (mass ≤50 g, speed ≤10 m/s) without cracking; the door interlock cuts off spindle power within 0.5 seconds if the door is opened during operation.

(2) Environmental Control: Stabilizing Machining Conditions

- Dust Prevention: Achieves IP54 or IP65 protection rating (per IEC 60529)—IP54 blocks most dust (≤50 μm particles) and splashing coolant; IP65 is fully dust-tight (suitable for graphite milling, where dust is highly conductive).

- Coolant Recovery: Integrates a slope-bottom design (slope angle 5°–10°) and drain ports (diameter ≥30 mm) to collect 95%+ of coolant, avoiding floor corrosion and reducing coolant waste by 30%.

- Temperature Regulation: For precision milling (e.g., mold machining with ±0.002 mm tolerance), the enclosure can be equipped with a forced ventilation system (airflow 200–500 m³/h) to control internal temperature fluctuation within ±1°C (prevents thermal deformation of the machine tool bed).

(3) Acoustic Noise Reduction: Meeting Workplace Standards

- Sound Insulation Layer: Outer layer (1.5–3 mm cold-rolled steel, sound insulation ≥25 dB) + inner layer (50–100 mm glass wool or polyurethane foam, sound absorption coefficient ≥0.8 at 1000 Hz).

- Sealed Structure: Gap between door and frame ≤0.2 mm, sealed with EPDM rubber strips (Shore hardness 60±5A) to block noise leakage.

- Actual Effect: Reduces external noise to ≤70 dB (meets OSHA’s 8-hour exposure limit of 90 dB), protecting operators’ hearing.

(4) Precision Maintenance: Extending Machine Life

- Chip Containment: Prevents chips from accumulating in guideways, ball screws, or spindle bearings—avoids wear on moving parts (e.g., ball screw life is extended by 50% when chips are isolated).

- Corrosion Prevention: For wet milling (using emulsion coolant), the enclosure’s inner surface is coated with anti-corrosion paint (epoxy resin, thickness 60–80 μm) to resist coolant erosion.

2. Technical Classification of CNC Mill Enclosures

(1) Classification by Structure

|

Structure Type

|

Design Features

|

Applicable Milling Machines

|

Key Parameters

|

|

Integral Enclosure

|

One-piece closed structure, front/side access doors, top exhaust port.

|

Vertical CNC mills (e.g., Haas TM-1, travel X≤1000 mm)

|

Weight: 200–500 kg; Opening time ≤3 s

|

|

Sectional Enclosure

|

Split into 2–4 modules, assembled on-site, adaptable to large travel ranges.

|

Horizontal CNC mills (e.g., DMG Mori NHX 5000)

|

X-axis coverage: 1500–3000 mm; Sealing gap ≤0.3 mm

|

|

Folding Enclosure

|

Flexible bellows + metal frame, retracts with X/Y-axis movement.

|

High-speed mills with long strokes (X≥2000 mm)

|

Stretch ratio: 1:5; Service life ≥1 million cycles

|

|

Customized Enclosure

|

Tailored to irregular machine shapes (e.g., 5-axis mills with A/C axes).

|

5-axis CNC mills (e.g., Mazak Variaxis i-600)

|

Clearance for A/C axis rotation: ≥50 mm

|

(2) Classification by Material

|

Material Type

|

Composition

|

Advantages

|

Limitations

|

|

Steel Enclosure

|

Outer: 1.5–3 mm cold-rolled steel; Inner: 50 mm sound-absorbing cotton.

|

High impact resistance (resists 10 J chip impact); durable.

|

Heavy (not suitable for mobile mills); poor visibility.

|

|

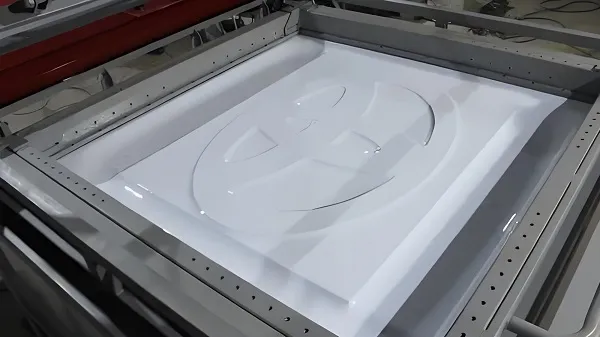

Acrylic Enclosure

|

5–10 mm thick cast acrylic (PMMA), with anti-scratch coating (hardness ≥3H).

|

High light transmittance (≥90%); easy to observe machining.

|

Low impact resistance (cracks if hit by ≥5 g chips); not heat-resistant (>80°C softens).

|

|

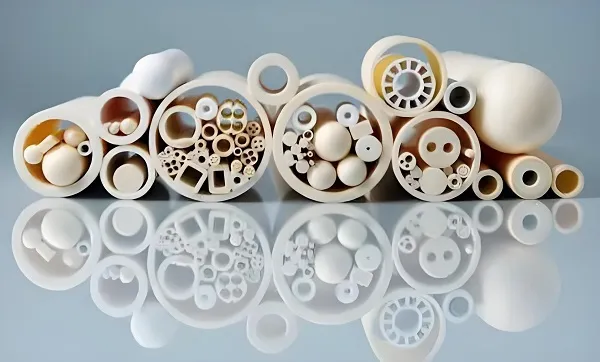

Composite Enclosure

|

Outer: Aluminum alloy (lightweight); Inner: Ceramic fiber (high-temperature resistance).

|

Lightweight (30% lighter than steel); heat-resistant (≤200°C).

|

High cost (2–3x steel enclosures); limited impact resistance.

|

3. Key Design Parameters for CNC Mill Enclosures

(1) Dimensional Matching

- Travel Coverage: Must fully cover the mill’s X/Y/Z axis strokes—e.g., for a mill with X=800 mm, Y=500 mm, Z=600 mm, the enclosure’s internal dimensions should be X≥850 mm, Y≥550 mm, Z≥650 mm (reserves 50 mm for cable movement and chip accumulation).

- Door Opening Size: For workpiece loading/unloading, the door width should be ≥ the maximum workpiece diameter + 100 mm (e.g., max workpiece φ300 mm → door width ≥400 mm).

(2) Sealing Performance

- Static Sealing: Gap between fixed parts (e.g., top cover and side panel) ≤0.1 mm, sealed with foam rubber strips (compression rate 30%–50%).

- Dynamic Sealing: For moving parts (e.g., folding bellows), use polyurethane-coated fabric (tensile strength ≥20 MPa) to maintain sealing while allowing axis movement (sealing efficiency ≥90% during movement).

(3) Mechanical Performance

- Impact Resistance: Outer shell withstands 10 J of impact (equivalent to a 50 g steel chip moving at 10 m/s) without permanent deformation.

- Opening/Closing Mechanism: Pneumatic or electric drive (for large enclosures, weight ≥500 kg) with a repeat positioning accuracy of ±0.5 mm (avoids door misalignment and sealing failure).

(4) Special Function Parameters

- High-Temperature Resistance: For dry milling of titanium (cutting zone temperature ≥800°C), the enclosure’s inner lining uses ceramic fiber (heat resistance ≤1200°C) to prevent material aging.

- Explosion-Proof Design: For milling of flammable materials (e.g., magnesium alloys), the enclosure is equipped with explosion vents (pressure relief area ≥0.1 m²/m³ of internal volume) and spark detectors (response time ≤10 ms).

4. Adaptation Design for Different CNC Mill Types

(1) Vertical CNC Mills

- Key Requirement: Easy access to the spindle (for tool changes) and workpiece loading.

- Design Features: Front double doors (opening angle 180°) + side maintenance doors; top exhaust port (connected to a dust collector, suction force ≥2000 Pa) for chip/dust removal.

- Example: For Haas VF-2 (X=914 mm, Y=457 mm), the enclosure uses an integral steel structure with a 6 mm thick acrylic window (for observing tool changes).

(2) Horizontal CNC Mills

- Key Requirement: Accommodate pallet changers (automatic workpiece switching).

- Design Features: Sectional structure (split into machine chamber and pallet chamber) with a sliding door between them (opens/closes in 2 seconds to allow pallet transfer); pallet chamber equipped with a separate coolant recovery system.

- Example: For Okuma MA-600H, the enclosure’s pallet chamber has a width of 1200 mm (to fit 630 mm pallets) and a dust-proof seal around the pallet changer.

(3) 5-Axis CNC Mills

- Key Requirement: Avoid interfering with A/C axis rotation (typical rotation range: A=-120° to +120°, C=0° to 360°).

- Design Features: Flexible top cover (using silicone-coated fiberglass fabric) and side bellows (stretch ratio 1:4) to allow multi-axis movement; minimum clearance between enclosure and rotating spindle head ≥50 mm.

- Example: For Hermle C 40 U, the enclosure uses a composite structure (steel frame + flexible fabric) to ensure no interference during 5-axis 联动.

5. Installation, Maintenance, and Troubleshooting

(1) Installation Precautions

- Leveling: The enclosure’s base must be level (levelness ≤0.1 mm/m) to avoid door misalignment (caused by uneven stress).

- Alignment: Align the enclosure with the mill’s guideways (parallelism ≤0.1 mm/m) to prevent dynamic sealing wear during axis movement.

- Electrical Connection: Connect the safety interlock to the mill’s CNC system (e.g., Fanuc 0i-MF) to ensure the spindle stops if the door is opened (test 10 times to confirm reliability).

(2) Routine Maintenance

|

Maintenance Item

|

Frequency

|

Operation Details

|

|

Sealing Strips

|

Every 3 months

|

Check for cracks/aging; replace EPDM strips if compression rate <20%.

|

|

Sound-Absorbing Layer

|

Every 2 years

|

Inspect for moisture (common in wet milling); replace glass wool if damp.

|

|

Pneumatic/Electric Drive

|

Every 6 months

|

Lubricate cylinders/motors (use lithium grease); check air pressure (0.6–0.8 MPa).

|

|

Acrylic Window

|

Weekly

|

Clean with isopropyl alcohol (avoid abrasive cleaners) to maintain transparency.

|

(3) Common Issues and Solutions

|

Common Issue

|

Cause

|

Solution

|

|

Coolant Leakage from Bottom

|

Drain port blocked by chips; slope angle too small (<5°).

|

Clear the drain port with a φ10 mm drill bit; adjust the base slope to 7°–10°.

|

|

Door Fails to Close Tightly

|

Door hinge worn (play >1 mm); sealing strip compressed unevenly.

|

Replace hinges (with precision bearings); reposition the sealing strip (ensure uniform compression).

|

|

Noise Reduction Effect Degrades

|

Sound-absorbing cotton falls off; gaps between panels increase.

|

Reattach cotton with high-temperature adhesive; add additional sealant to gaps.

|

|

Acrylic Window Scratches

|

Cleaned with abrasive cloth; hit by small chips.

|

Polish with 3000-grit sandpaper (for minor scratches); replace the window (for deep scratches, >0.5 mm).

|

6. Future Trends in CNC Mill Enclosure Technology

(1) Intelligent Monitoring

- Sensor Integration: Install temperature/humidity sensors (accuracy ±0.5°C, ±5% RH) and vibration sensors (detecting enclosure loose parts) to transmit data to the mill’s CNC system—alerting operators if temperature exceeds 30°C or vibration amplitude >0.1 g.

- Predictive Maintenance: Use AI algorithms to analyze maintenance data (e.g., sealing strip wear rate) and predict replacement times (accuracy ≥85%), avoiding unexpected failures.

(2) Lightweight and High-Strength

- Material Innovation: Adopt carbon fiber composites (density 1.7 g/cm³, 1/5 of steel; tensile strength 3000 MPa) to reduce enclosure weight by 40% (suitable for mobile mills) while maintaining impact resistance.

- Structural Optimization: Use topology optimization (via ANSYS) to reduce material usage by 20% without compromising strength (e.g., hollowed-out steel frames).

(3) Green and Eco-Friendly

- Eco-Materials: Replace glass wool (non-recyclable) with recycled polyester fiber (sound absorption coefficient ≥0.7) and water-based anti-corrosion paint (VOC content ≤50 g/L).

- Energy Saving: Integrate LED lighting (power ≤10 W) and energy-efficient fans (power ≤50 W) to reduce the enclosure’s energy consumption by 30% compared to traditional designs.