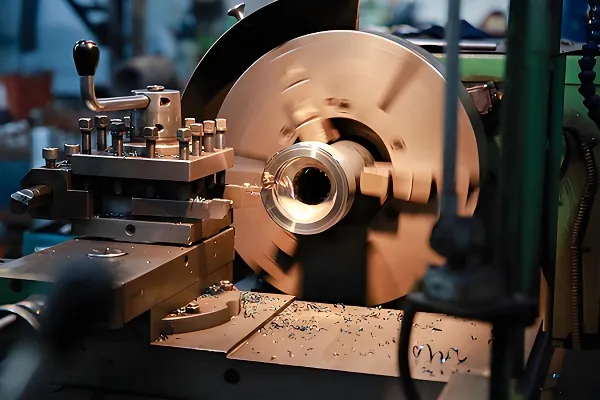

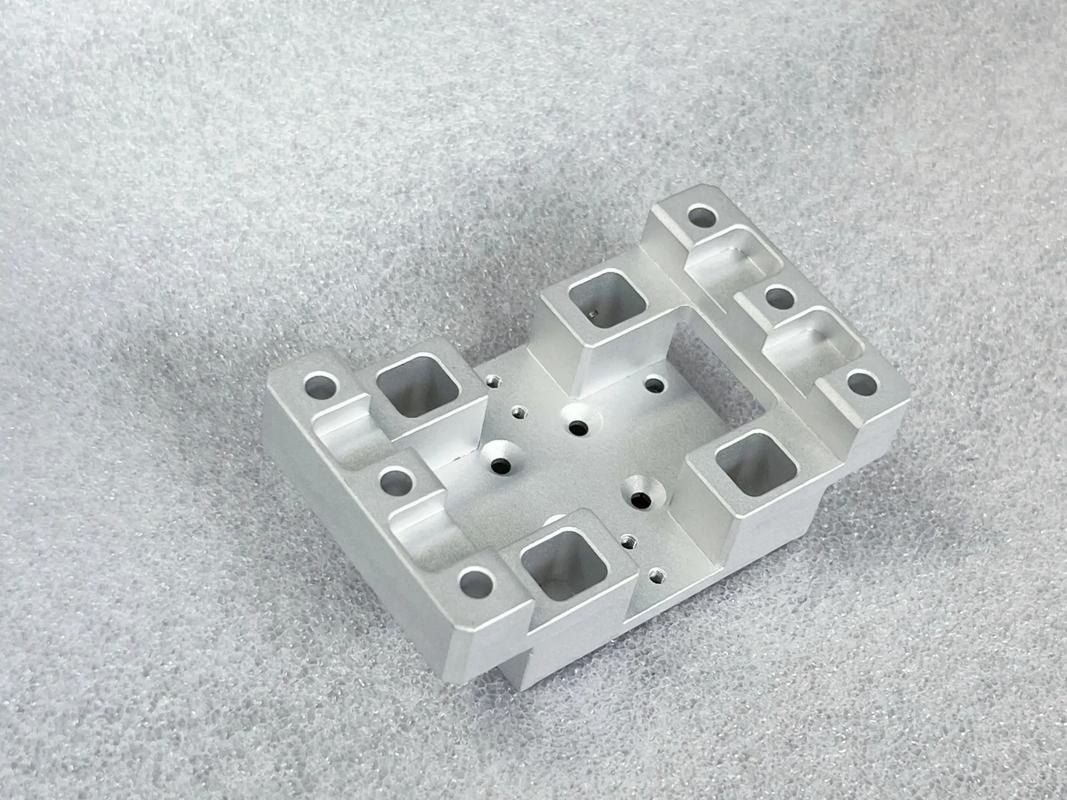

Aluminum, as a core material in fields such as aerospace, automotive manufacturing, and electronic equipment, is widely used in CNC machining due to its advantages of lightweight, corrosion resistance, and good thermal conductivity. However, aluminum’s characteristics of low melting point and high viscosity often lead to issues like chip fusion, premature tool failure, and poor surface precision during machining. Even experienced operators may encounter the dilemma of “a program that worked last time causing tool breakage this time” due to improper parameter settings or incorrect tool selection. Based on professional CNC machining experience, this article expands on the key techniques, parameter details, and practical solutions for aluminum CNC machining while building on the original core knowledge points, helping enterprises and operators achieve efficient and high-precision aluminum machining.

I. Core Pain Points in Aluminum CNC Machining: Beyond “Tool Chipping”

Before discussing best practices, it is necessary to clarify the unique challenges of aluminum machining—these issues are not isolated but interconnected and form a vicious cycle:

- Chip Fusion and Built-Up Edge (BUE) : Aluminum has a melting point of only 660°C. During machining, cutting heat easily overheats loose chips (local temperatures can exceed 800°C), causing them to fuse to the tool’s cutting edge or chip flutes. More seriously, under high temperatures, aluminum forms a “built-up edge” (a metal adhesion) on the tool surface. This not only dulls the cutting edge and increases cutting resistance but also scratches the workpiece surface, raising the surface roughness from Ra1.6 to Ra6.3 or higher.

- Tool Overload Failure : Although aluminum is “soft,” tool chipping can cause the actual cutting load on the tool to far exceed its design limits. For example, if a 2-flute end mill is clogged with chips, the cutting force may increase by 30%-50%, eventually leading to tool chipping or spindle overload alarms.

- Workpiece Thermal Deformation : Aluminum has a coefficient of thermal expansion 2-3 times that of steel. Local temperature rises during machining (especially for thin-walled parts and deep-cavity parts) can cause dimensional deviations in the workpiece. For instance, a 100mm-long aluminum thin-walled part may deform by 0.23mm with a temperature difference of 10°C, exceeding the tolerance requirements of precision parts.

- Chip Evacuation Difficulties : During deep-cavity or blind-hole machining, chips tend to accumulate at the bottom, forming “aluminum slag clumps.” These clumps not only hinder tool feed but also repeatedly rub against the workpiece surface, deteriorating machining quality.

II. Five Best Practices for Aluminum CNC Machining (In-Depth Expanded Version)

To address the above pain points and combined with the machining characteristics of different aluminum alloys (e.g., 6061, 7075, 5052), the following provides actionable solutions from three dimensions: parameters, tools, and operations:

1. Optimize Feed Rate and Spindle Speed: Precisely Match Aluminum Alloy Characteristics

The core principle of aluminum machining is “high-speed cutting with reasonable feed,” but adjustments must be made based on alloy type to avoid a “one-size-fits-all approach”:

- Differentiated Setting of Cutting Speed (Vc) :

- Free-machining aluminum alloys (e.g., 6061-T6): When using carbide tools, Vc is recommended to be 400-550 m/min (close to the cutting speed of wood). This not only reduces chip residence time but also lowers the risk of tool chipping.

- High-strength aluminum alloys (e.g., 7075-T6): Due to their higher hardness (approximately 150 HB), Vc should be reduced to 350-450 m/min to prevent the tool edge from chipping due to impact overload.

- Thin-walled/deformable parts: Vc can be appropriately increased to 500-600 m/min, but high-pressure cooling must be used to reduce machining heat accumulation.

- Key Logic for Feed Rate per Tooth (Fz) :

The feed rate must match the cutting speed to avoid the mistake of “high spindle speed + slow feed.” If the spindle speed (n) is too high but the feed rate is too low, the tool will repeatedly rub against the aluminum surface (instead of shear cutting), causing a sudden rise in local temperature. Taking a 2-flute carbide end mill as an example:- When machining 6061, Fz is recommended to be 0.15-0.2 mm/tooth, and the total feed rate (F = n×z×Fz) is approximately 1200-1800 mm/min.

- When machining 7075, Fz can be reduced to 0.12-0.18 mm/tooth to balance cutting efficiency and tool life.

- Practical Tip : When machining a new aluminum alloy for the first time, use the “trial cutting method”: first set a slightly lower Vc (e.g., 300 m/min) and observe the chip shape. If the chips are “short and coiled” (ideal state), gradually increase Vc; if “long 丝状” (long and thread-like) or “fusion lumps” appear, reduce Vc and check the cooling effect.

2. Chip Cleaning: From “Passive Cleaning” to “Proactive Prevention”

Chip accumulation is the “root cause of all evils” in aluminum machining. Efficient chip evacuation solutions must be selected based on machining scenarios:

- Shallow Cutting Depth + High-Frequency Chip Evacuation : During deep-cavity machining, avoid a one-time cutting depth exceeding 1/3 of the tool diameter (e.g., for a 10mm-diameter tool, the single cutting depth ≤ 3mm). Adopt “layered cutting”—after each cutting layer, quickly retract the tool and use compressed air (0.6-0.8 MPa pressure) to blow away chips at the bottom. For blind-hole machining, add a “pause + air blowing” command to the program to ensure complete chip evacuation.

- Scientific Selection of Cooling Media :

- General milling/drilling: Compressed air is sufficient (low cost, no liquid accumulation), but pay attention to the air blowing direction—it should be inclined to align with the contact point between the tool edge and the workpiece, rather than directly blowing at the chip accumulation area.

- Deep-cavity/high-speed cutting: It is recommended to use water-based emulsion (5%-8% concentration) or oil-based coolant. The former has good cooling effects (suitable for preventing deformation of thin-walled parts), while the latter has strong lubricity (reducing tool chipping). Avoid using pure cutting oil (high viscosity, easy to stick to chips).

- Special Scenario Solution : When machining aluminum thin-walled parts, a “vacuum chip suction” device can be used—chips are directly sucked away by negative pressure, which not only prevents chips from scratching the workpiece but also reduces machining heat transfer.

3. Tool Flute Count Selection: Fewer Flutes ≠ Lower Efficiency, Chip Evacuation is Priority

The core requirement for tools in aluminum machining is “large chip evacuation space,” so tools with fewer flutes are preferred. However, a balance between rigidity and chip evacuation efficiency must be maintained:

- 2-Flute Tools: Universal First Choice : The chip flute volume of a 2-flute end mill/end mill is 2-3 times that of a 4-flute tool, enabling rapid aluminum chip evacuation. It is especially suitable for face milling and slot machining. For example, when machining wide slots (width > 10mm) in 6061, a 2-flute tool can achieve clog-free cutting, with a surface roughness of up to Ra1.6 or lower.

- 1-Flute/3-Flute Tools: Supplementary for Special Scenarios :

- 1-flute tools (e.g., single-flute end mills): They have the largest chip evacuation space and are suitable for deep-cavity machining (depth > 5 times the tool diameter) or high-viscosity aluminum alloys (e.g., 5052). However, their rigidity is poor, so the feed rate must be reduced (Fz ≤ 0.1 mm/tooth).

- 3-flute tools: They have better rigidity than 2-flute tools and are suitable for semi-finishing (balancing efficiency and surface precision). However, their chip flutes are smaller, so high-pressure cooling must be used to avoid chip accumulation.

- Key Impact of Tool Length : Tools with fewer flutes have weaker rigidity, so the shortest possible tool should be used for the application, and tool deflection should be monitored—especially when using small-diameter end mills.

4. Tool Material: Carbide is the Only Choice, Model Must Match

In aluminum machining, the hardness of the tool material directly determines its service life. High-Speed Steel (HSS) is completely obsolete for the following reasons:

- Limitations of High-Speed Steel: HSS has a hardness of approximately HRC60-65 and poor high-temperature resistance (it softens when the temperature exceeds 500°C). When machining aluminum, the tool edge is prone to chipping due to tool chipping, with a service life only 1/10-1/5 that of carbide.

- Selection of Carbide Models :

- General Scenarios: WC-Co carbide (tungsten-cobalt carbide) with a Co content of 6%-10% (higher Co content means better toughness). For example, YG6X (6% Co content) has a hardness of HRA91-92 and is suitable for free-machining aluminum alloys such as 6061.

- High-Strength Aluminum Alloys (7075): Ultra-fine grain carbide (grain size 0.5-1 μm), such as YG8N, is recommended. It has stronger wear resistance and can withstand higher cutting impacts.

- Tool Edge Treatment : Tools for aluminum machining require “sharp edges + polished chip flutes.” If the tool edge has burrs (e.g., after grinding without passivation), it will directly cause chip adhesion. The surface roughness of the chip flutes must be ≤ Ra0.4 to reduce friction between chips and the flute walls.

5. Tool Coatings: Reject “Gimmicky Coatings,” Choose “Targeted Coatings”

The coating logic for aluminum machining is “low friction, low reactivity,” and traditional coatings are counterproductive:

- Coatings to Avoid Absolutely : Coatings such as TiN (golden) and TiAlN (purple-black) are not suitable for aluminum machining. TiN coatings have high surface roughness (Ra0.8-1.2) and are prone to chip adhesion; TiAlN reacts chemically with aluminum at high temperatures to form Al-Ti alloys, leading to more severe tool chipping and a 50% or more reduction in tool life.

- Recommended Coating/Uncoated Solutions :

- Uncoated Carbide: Low cost, suitable for mass machining of free-machining aluminum alloys such as 6061, provided the tool edge is properly polished.

- DLC (Diamond-Like Carbon Coating): Has a friction coefficient of only 0.05-0.1 (much lower than the 0.3-0.4 of uncoated tools), which can significantly reduce aluminum adhesion. It is suitable for precision machining (e.g., thin-walled slots in electronic parts).

- TiB2 (Titanium Diboride Coating): Has extremely strong chemical inertness, does not react with aluminum or aluminum alloys, and is high-temperature resistant (up to 800°C). It is suitable for high-speed machining of high-strength aluminum alloys such as 7075.

- ZrN (Zirconium Nitride Coating): Has high hardness (HV2500) and a smooth surface, balancing wear resistance and chip evacuation. It is a cost-effective general-purpose coating for aluminum machining.

III. Additional Practical Tips: Resolving “Complex Issues” in Aluminum Machining

- Tip for Preventing Deformation of Thin-Walled Parts : When machining aluminum thin-walled parts with a thickness < 3mm, adopt “symmetrical cutting” (cutting from both sides to the center) to avoid bending caused by one-sided force. At the same time, reduce the cutting depth (≤ 1mm) and use cold air cooling (-5°C ~ 10°C) to reduce thermal deformation.

- Tool Wear Monitoring : In aluminum machining, the early sign of tool wear is “chip color change”—normal chips are silvery white. If they turn dark gray or blue, it indicates that the tool has become dull and must be replaced immediately (continued use will exacerbate tool chipping).

- Optimization of Workpiece Clamping : Use “soft jaws” (made of polyurethane or aluminum alloy) to clamp aluminum parts to avoid surface scratches caused by hard jaws (steel material). For large plate parts, adopt “multi-point support” (support point spacing ≤ 200mm) to prevent deformation due to gravity during machining.

IV. Summary: The “Success Formula” for Aluminum CNC Machining

Efficient aluminum CNC machining = appropriate parameters (matching alloy type) + fewer-flute carbide tools (uncoated or DLC/TiB2 coated) + proactive chip evacuation (layered cutting + high-pressure cooling/air blowing).

If you still face complex issues during practical operations (e.g., deep-cavity chip adhesion, thin-walled deformation), you can improve your practical skills through professional CNC training (such as the CNC Training Center mentioned in the article). This type of training usually combines hands-on exercises with mainstream equipment like Haas, helping operators quickly master the full-process skills of “parameter debugging – fault troubleshooting” and fundamentally resolve aluminum machining pain points.

Mastering the above best practices can not only improve the efficiency of aluminum machining (extending tool life by 2-3 times and reducing the scrap rate to below 1%) but also ensure the quality of precision aluminum parts, providing reliable support for production in high-end fields such as aerospace and electronics.