In the field of precision manufacturing, “customization” and “high precision” are the core demands of corporate clients. Xiamen Goldcattle Industry and Trade Co., Ltd. (Xiamen Goldcattle), with 26 years of in-depth experience, has long been a benchmark service provider of customized CNC metal/plastic components among national high-tech enterprises. Covering mold design, CNC machining, injection molding, 3D printing, and stamping production, Goldcattle focuses on “end-to-end solutions” to address clients’ pain points in industries such as automotive, machinery, medical, and electronics—including “difficult component adaptation,” “substandard precision,” and “long delivery cycles—while committed to building long-term win-win global partnerships.

I. Get to Know Goldcattle: A 26-Year-Old Expert in Customized Manufacturing

As an enterprise with a quarter-century of manufacturing experience, Goldcattle has a clear and precise core positioning: “Customer demand-oriented, providing customized component solutions from design to assembly.” Unlike the “single-production” model of traditional processing factories, Goldcattle has adhered to the principles of “high precision, high efficiency, and integrity in service” since its establishment, integrating the concept of “customer first, sustainable operation” into every production link.

Today, Goldcattle has evolved into a national high-tech enterprise integrating “R&D, production, and service,” with core business covering five major sectors:

- Precision CNC Machining: Including milling, turning, drilling, boring, and multi-axis machining. In particular, its 5-axis machining equipment can achieve an ultra-high tolerance of ±0.005mm, meeting high-precision requirements in scenarios such as aerospace and medical devices.

- Mold Development & Manufacturing: Single-cavity molds, double-cavity molds, thin-wall molds, and thermoplastic precision molds. With “high precision and long service life,” they ensure stable product quality during mass production.

- Injection Molding: Producing single-color parts, multi-color parts, insert-molded plastic parts, and micro-plastic parts. The finished products feature precise dimensions, smooth surfaces, and durability, adapting to segmented needs such as electronic components and automotive interiors.

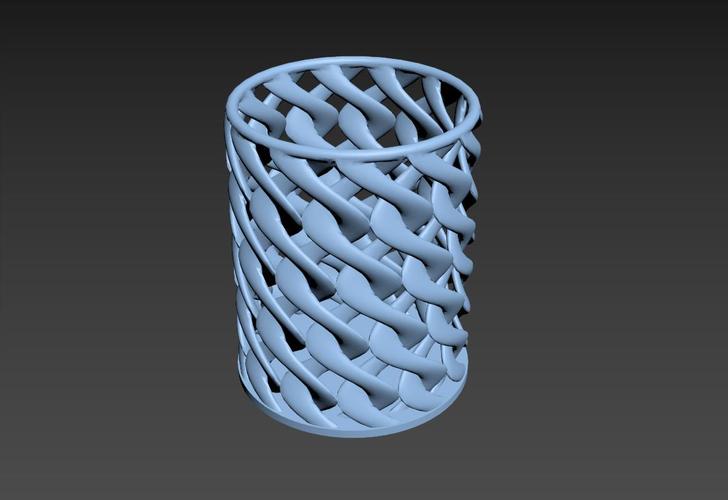

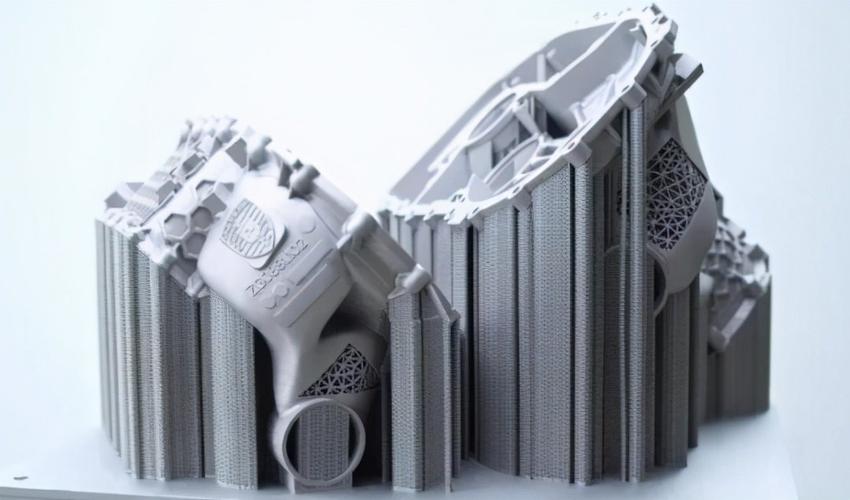

- 3D Printing Services: Supporting various materials (plastics, metals, etc.) for customizing complex-structured models, components, artistic decorations, and even toys (e.g., popular 3D-printed dragon/dragon egg models), balancing precision and creativity.

- Metal Stamping: Manufacturing high-strength, wear-resistant metal stampings, bent parts, and deep-drawn parts with excellent surface finish, widely used in mechanical accessories and hardware tools.

Whether clients provide drawings or samples, Goldcattle’s professional team can analyze and optimize requirements, transforming “custom needs” into standardized production processes to achieve seamless transition from “small-batch prototypes” to “large-batch mass production.”

II. Capability Breakdown: Five Core Businesses Addressing Custom Pain Points Across Industries

Goldcattle’s core competitiveness lies in “simplifying complex needs and maximizing precision standards.” For the differentiated demands of clients in different industries, its five business sectors have clear value positions, making “customization” no longer synonymous with “high cost and high risk.”

1. CNC Machining: ±0.005mm Precision for Complex Component Needs

In CNC machining, “precision” is Goldcattle’s core label. Equipped with 5-axis machining equipment, it can easily handle complex processing of various materials (stainless steel, aluminum alloys, brass, etc.). Whether it is precision accessories for automotive engines or core movement components for watches, it achieves “sub-millimeter” error control.

Segmented services include:

Segmented services include:

- CNC Milled Parts: 3D processing of irregular parts with a surface roughness of up to Ra0.8μm.

- CNC Turned Parts: Suitable for shaft and disc parts, enabling automatic feeding for mass production.

- Multi-Axis Machining: 3-5 axis linkage to address complex curved surfaces (e.g., special-shaped structures of aerospace components) that cannot be processed by traditional 3-axis equipment.

- EDM (Electrical Discharge Machining): Achieving precision forming of high-hardness materials (e.g., hardened steel) without cutting force to avoid component deformation.

2. Mold & Injection Molding: End-to-End Control from “Mold” to “Part”

As the “source of customized components,” Goldcattle’s mold manufacturing capability directly determines the stability of subsequent products. Its mold team has over 10 years of experience and can design single-cavity, double-cavity, or even multi-cavity molds based on client needs. Especially in thin-wall molds (minimum wall thickness of 0.1mm) and thermoplastic molds, it balances “production efficiency” and “mold service life”—the service life of ordinary molds can exceed 500,000 cycles, far above the industry average.

In injection molding, Goldcattle further refines its services:

- Single-Color/Multi-Color Injection Molding: Meeting dual needs of product appearance and functionality (e.g., two-color buttons for automotive interiors).

- Insert Injection Molding: Integrating metal and plastic parts into one piece to enhance product structural strength.

- Micro-Injection Molding: Achieving 0.05mm dimensional tolerance control for small-sized parts such as electronic components and medical consumables.

3. 3D Printing & Stamping: Flexibly Meeting “Small-Batch” and “High-Strength” Needs

For “small-batch, complex-structured” custom needs, Goldcattle’s 3D printing service is the optimal solution—enabling rapid production without mold opening. Covering materials such as PLA, ABS, nylon, and stainless steel, it can produce both product prototypes (e.g., mechanical part samples) and end products (e.g., customized toy models, artistic decorations) with a precision of up to 0.1mm and 100% complex structure realization rate.

For “large-batch, high-strength” metal component needs, Goldcattle’s stamping production line offers:

- Metal Stampings: Mass forming via precision molds, suitable for automotive chassis accessories and hardware connectors.

- Metal Bent/Drawn Parts: Cold processing of metal sheets to ensure component strength and flatness.

- Metal Die-Castings: For materials such as aluminum alloys and zinc alloys, producing large-sized parts with complex structures (e.g., motorcycle frame accessories).

III. Industry Customization: Focusing on Six Sectors to Provide Scenario-Specific Solutions

Goldcattle understands that component demands vary greatly across industries—automotive parts need to fit vehicle specifications, medical parts must meet sterility standards, and watch parts require extreme miniaturization. To this end, Goldcattle has launched customized services for six key industries, making “customization” more scenario-adaptable.

| Industry Sector | Custom Product Types | Core Advantages & Value |

|---|---|---|

| Automotive | Engine accessories, interior parts, chassis connectors | Precision processing per vehicle drawings to fit different brand models; high temperature/aging resistance, complying with automotive industry quality standards. |

| Machinery | Gears, bearings, transmission components | Material optimization for different working conditions (e.g., high temperature, high pressure) to enhance component wear resistance and service life, reducing mechanical failure rates. |

| Motorcycle | Frame accessories, control system parts | Custom design to fit different displacement models; high-strength materials ensuring riding safety; surface treatment (e.g., electroplating) enhancing appearance texture. |

| Hardware | Connectors, fasteners, tool accessories | Custom dimensions and structures per application scenarios; anti-rust treatment (e.g., galvanization, chrome plating) for home and industrial use. |

| Equipment | Instrument housings, internal transmission parts | Precise fit with equipment assembly dimensions; lightweight materials (e.g., aluminum alloys) reducing overall equipment weight and improving portability. |

| Watchmaking | Movement gears, watch case accessories | Micro-processing (minimum size of 0.5mm); high precision ensuring smooth movement operation; metal surface polishing enhancing texture. |

Whether for global automotive component suppliers or local small and medium-sized machinery enterprises, Goldcattle ensures “one-time adaptation success” of custom parts through the process of “one-on-one demand communication → drawing optimization → sample confirmation → mass production.”

IV. Trust Goldcattle: Four Core Pillars Behind 26 Years of Reputation

In the B2B precision manufacturing sector, “trust” stems from “visible strength.” Goldcattle’s long-term trust from over 100 global partners is supported by four core pillars:

1. Qualification Certifications: International Standards for Compliance Peace of Mind

Goldcattle has obtained multiple international authoritative certifications, including ISO 9001:2000 Quality Management System Certification, SGS Material Testing Certification, CE Product Safety Certification, and RoHS Environmental Certification. From “production processes” to “product output,” all comply with the compliance requirements of mainstream global markets—whether medical parts exported to Europe or automotive accessories supplied to North America, they can easily pass local quality inspections.

2. Equipment & Team: Professionalism Guarantees Precision

- Equipment Strength: Over 100 sets of professional production and quality inspection equipment, including 5-axis CNC machining centers, precision injection molding machines, 3D printers, and coordinate measuring machines (CMMs). The CMMs achieve 0.001mm inspection precision, ensuring “100% inspection pass” for each batch of parts.

- Team Strength: The core technical team has an average of over 8 years of experience, covering industrial design, mold development, CNC programming, and quality inspection, providing clients with end-to-end technical support from “demand analysis → drawing optimization → process design.”

3. Experience Accumulation: Zero Major Quality Incidents in 26 Years

From 1999 to 2025, Goldcattle has served over 500 clients without a single major quality incident in 26 years. This “zero-incident” record stems from its “three-level quality inspection process” (first-piece inspection → in-process inspection → full finished product inspection) and the responsibility of treating “every part as its own product.”

4. Client Reputation: 5/5 Star Cooperation Recognition

In client reviews, “high precision,” “on-time delivery,” and “professional service” are the most frequently mentioned keywords. A automotive component client commented: “Goldcattle’s CNC parts have precise tolerance control, with a pass rate of 99.8% during mass production, saving us significant rework costs.” Such recognition drives Goldcattle to continuously optimize its services.

V. Partner with Goldcattle: Three Simple Steps to Start Your Customization Journey

For clients with custom needs, Goldcattle simplifies the “complex process” into three steps to transform “demand” into “finished products”:

- Demand Communication: Provide drawings/samples and requirements (e.g., material, precision, batch size, delivery cycle) via the 400 hotline, online form, or email. Goldcattle’s technical team will respond within 24 hours.

- Program Confirmation: Goldcattle issues a process plan and quotation. For sample needs, prototypes can be completed within 3-7 days. Mass production starts after client confirmation.

- Finished Product Delivery: After production, a quality inspection report is provided. Clients can choose on-site pickup or logistics delivery (national delivery within 3 days; export customs clearance assistance available).

Whether for small-batch prototypes (1-100 pieces) or large-batch production (10,000+ pieces), Goldcattle meets clients’ diverse needs with “flexible production capacity allocation” and “stable quality control.”

VI. Goldcattle’s Vision: Empowering Global Industrial Upgrading with Precision Manufacturing

Over 26 years, Goldcattle has always aimed to “become a world-leading service provider of customized components.” From Xiamen to the whole country, and then to serving global clients, its core remains the original aspiration of “customer demand-centricity.” In the future, Goldcattle will continue to invest in R&D, upgrade core technologies such as 5-axis machining and 3D printing, expand customized services in high-end fields (e.g., medical, aerospace), and provide “more precise, efficient, and worry-free” manufacturing solutions for more industry clients.

If you are looking for a “high-precision, reliable” supplier of customized CNC metal/plastic components, Xiamen Goldcattle—a national high-tech enterprise with 26 years of experience—is ready to assist you. Let’s build a high-quality win-win cooperation journey together.

Inquiry Hotline: +86-18150097490

Email: charlie@plasticmetalparts.com

Official Website: https://www.xmgoldcattle.com/

Email: charlie@plasticmetalparts.com

Official Website: https://www.xmgoldcattle.com/