Standard precision brass components are industrial parts manufactured from brass via high-precision processes, with dimensional accuracy reaching the micron level and compliance with international standards such as ISO and ANSI. Combining brass’s corrosion resistance, electrical conductivity, and the stability of precision machining, they are widely used in electronics, automotive, machinery, aerospace, and other fields. As core supports for the efficient operation of equipment, they are indispensable high-precision basic components in industrial manufacturing.

1. Definition of Precision Brass Components

Standard precision brass components refer to parts made from brass as the base material, with dimensional tolerances (e.g., ±0.005mm) and geometric tolerances (e.g., parallelism ≤0.01mm) that meet strict industrial standards through professional processing technologies. The key difference from ordinary brass components lies in “precision” — real-time inspection (such as coordinate measuring machine (CMM) measurement) is required to control details, ensuring compatibility with high-precision equipment (e.g., electronic sensors, automotive gearboxes) and preventing assembly errors from affecting overall performance.

2. Materials for Precision Brass Components

The mainstream materials are copper-zinc alloys, with common grades and their characteristics as follows:

- H62 (62% copper content): Cost-effective with moderate strength, suitable for manufacturing precision parts with simple structures (e.g., connector pins);

- H65 (65% copper content): Superior ductility and electrical conductivity, ideal for precision components requiring conductivity in the electronics field (e.g., terminals);

- Hpb59-1 (1% lead content): Excellent machinability, easy to process complex structures (e.g., precision valve cores), suitable for mass production;

- HSn70-1 (1% tin content): Enhanced corrosion resistance and high-temperature resistance, applicable to high-temperature or strong-corrosion scenarios (e.g., automotive fuel system parts).

Material selection must align with application scenarios (e.g., temperature, load, conductivity requirements) to ensure the part’s performance matches the working conditions.

3. Functions of Precision Brass Components

They play core roles in various industries, as detailed below:

- Electronics Field: Used as connectors and contacts to ensure stable current transmission and prevent equipment failures caused by poor contact;

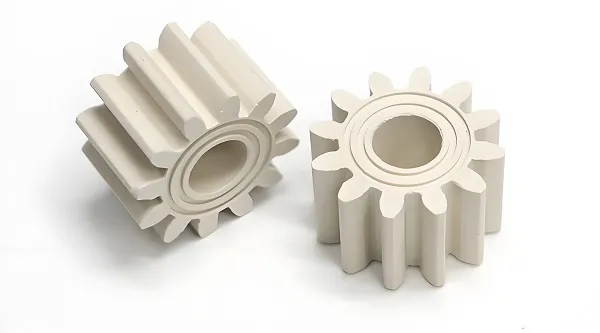

- Automotive Field: Manufactured into sensor housings and precision gears, withstanding high temperatures and vibrations of engines to ensure driving safety;

- Machinery Field: Applied in valve cores and bearing sleeves to control fluid flow or reduce mechanical wear, extending equipment service life;

- Aerospace Field: Produced as small precision components (e.g., instrument panel parts) to adapt to harsh environments such as high-altitude low pressure and strong radiation.

4. Processes for Precision Brass Components

The complete process chain covers 4 core links, with strict temperature and pressure control required for each link:

- Pretreatment: Material cutting (sizing according to dimensions) and surface degreasing (preventing oil stains from affecting precision during processing);

- Forming Processes: Casting (suitable for complex shaped parts), forging (improving material density and enhancing strength), and stamping (mass production of simple structures, e.g., thin sheet parts);

- Finishing Processes: Annealing (reducing material hardness for subsequent processing), polishing (improving surface finish, Ra ≤ 0.8μm), and electroplating (nickel/chromium plating to enhance corrosion resistance);

- Inspection Processes: Sampling inspection after each link (e.g., using image measuring instruments to check dimensional deviations) and 100% full inspection of finished products to ensure compliance with standards.

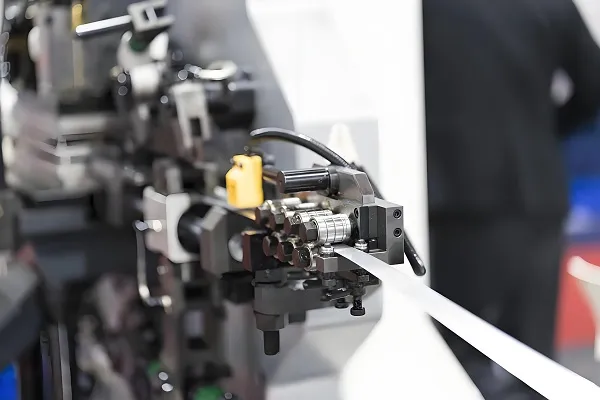

5. Machining of Precision Brass Components

Focusing on “high precision and high efficiency”, the mainstream machining methods are as follows:

- CNC Machining: Including milling, turning, and drilling, with an accuracy of ±0.005mm. It is suitable for complex structures (e.g., multi-hole precision parts) and supports small-batch customization;

- Automated Production Lines: Combining stamping and CNC machining, suitable for mass production (e.g., daily output of over 10,000 pieces) to reduce human errors;

- Specialized Machining: For ultra-small size parts (e.g., pins with a diameter < 1mm), laser cutting and electrical discharge machining (EDM) are used to avoid deformation caused by mechanical processing.

During machining, parameters must be adjusted according to materials (e.g., setting the cutting speed of Hpb59-1 to 80-100m/min to prevent tool sticking), and data must be recorded in real time to facilitate quality traceability.

6. Advantages of Precision Brass Components

Compared with precision parts made of stainless steel and aluminum alloy, their core advantages are significant:

- High Material Cost-Effectiveness: The procurement cost of brass is lower than that of stainless steel, and its processing difficulty is low, reducing the comprehensive cost by 20%-30% during mass production;

- Wide Performance Adaptability: It has inherent corrosion resistance, eliminating the need for frequent maintenance; its electrical conductivity is superior to that of aluminum alloy, making it suitable for electronic conductive scenarios;

- Strong Precision Stability: Brass has a low thermal expansion coefficient (19.5×10⁻⁶/℃), so it is not prone to deformation due to temperature changes after processing, with a long-term precision attenuation rate of < 5%;

- High Customization Flexibility: Easy to cut and form, it can be manufactured into special-shaped structures (e.g., bent, multi-hole parts) to meet personalized needs.

7. FAQ about Precision Brass Components

- Q: What is the service life of standard precision brass components?

A: Under normal temperature and non-strong corrosion environments, the service life is 5-10 years; with electroplating treatment or low-load use, the service life can be extended to more than 15 years.

- Q: Can they be used in high-temperature environments?

A: Ordinary brass is suitable for temperatures ≤200℃; for high-temperature scenarios (200-300℃), grades such as HSn70-1 can be customized, increasing the temperature resistance by 30%.

- Q: What parameters are required for customization?

A: It is necessary to specify dimensional drawings (including tolerance requirements), application scenarios (temperature, load, medium), and surface treatment needs (e.g., polishing/electroplating) to facilitate material and process recommendations.

- Q: How to verify whether the part precision meets the standards?

A: We provide CMM inspection reports and image measurement data; customers can conduct on-site sampling and re-inspection, and non-conforming products will be reworked free of charge.

8. Customization of Precision Brass Components

We provide a full-process customization service covering “demand-design-sample-mass production-after-sales”:

- Demand Communication: Dedicated technical consultants communicate details and recommend optimal materials based on scenarios (e.g., H65 for electronic parts, Hpb59-1 for mechanical parts);

- Solution Output: Issue 3D drawings and process plans within 3 days, clarifying costs and timelines;

- Sample Production: Complete sample prototyping within 3-5 days, supporting free inspection and modification;

- Mass Production: Deliver small batches (10-100 pieces) within 5-7 days and large batches (1,000+ pieces) within 10-15 days, with full-process visual progress tracking;

- After-Sales Support: If there are precision deviations or quality issues, we will respond within 24 hours and provide free rework or replacement.

If you are looking for standard precision brass components suitable for electronics, automotive, or machinery fields, or have customization needs for complex structures and special working conditions (e.g., high temperature, high conductivity), please feel free to leave a message! With 10 years of experience in precision brass processing and CNC equipment accuracy of ±0.005mm, we can provide free sample prototyping and technical solutions to make your equipment more stable in precision and more worry-free in procurement — we look forward to your message and working together to create cost-effective precision components!