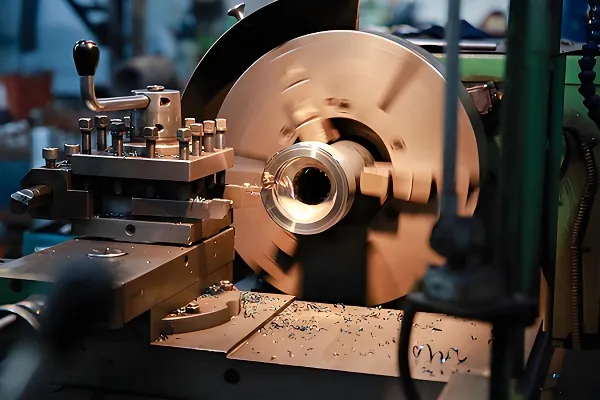

First, let’s figure out what “online CNC machining” is: A while back, there were super cool machines that could cut materials like metal and plastic into the shapes you want really precisely—like carving small parts or drilling tiny holes. That’s just “CNC machining.” Now, they’ve added an “internet feature” to it, and that’s “online CNC machining”—put simply, it uses computers and the internet to help make the whole process of cutting materials and making parts way easier.

The main thing about it is: it’s all about everyone working together with computers, plus the machines cutting really accurately. This makes all the steps of machining run smoothly.

1. No need to go to factories—you can share what you need online

You don’t have to make a special trip to a factory. You can do everything from home or school on a computer:

- First, upload the “3D drawings” of the part you want to make (like the 3D pictures you draw on a tablet when you play with building blocks). They might be called formats like STL or STEP, but you don’t have to remember those names—just know they’re 3D drawings!

- Then tell it the details: what material to use (like lighter aluminum or harder stainless steel), how precise the cut needs to be (no tiny mistakes allowed), and how to treat the surface (like making it shiny—they call that “anodizing,” but you don’t have to remember that term either).

- The computer will automatically tell you “how much this costs” and “how long it’ll take to make.” You can ask for a price and place an order right away—no need to keep making calls or going to factories. It saves a lot of hassle!

2. Check anytime if your part is “done yet”

After you place an order, the online platform sends info on “how to make this part” (like what steps the machine needs to take) to partner factories or its own workshops.

You don’t have to keep asking, “Is my part ready yet?” Just open your computer and check the progress right away—things like “We’ve got the materials ready!” “We’re cutting it now!” “We checked it—no problems!” “It’s ready to ship!” It’s super clear, no confusion at all.

3. Small batches or custom parts are affordable too

This way of machining is perfect for making “small numbers of parts you designed yourself”—like parts for a small model or just a few parts you need. It’s not for making hundreds or thousands of the same part at once.

Before, factories didn’t like taking these “small orders”—they’d even charge a lot of money for them. But now, online platforms group together lots of people’s “small orders” and arrange for the machines to work well. So making small batches of parts isn’t expensive anymore, and you can get them made easily.

To put it simply: It’s like opening an “online shop” for “precision machining.” Whether you’re a small company making hardware, a car part maker, or just someone who wants to make a small precision part—you can use it as easily as online shopping! Plus, with computers helping everyone work together, parts get made faster, and you can see the progress clearly.