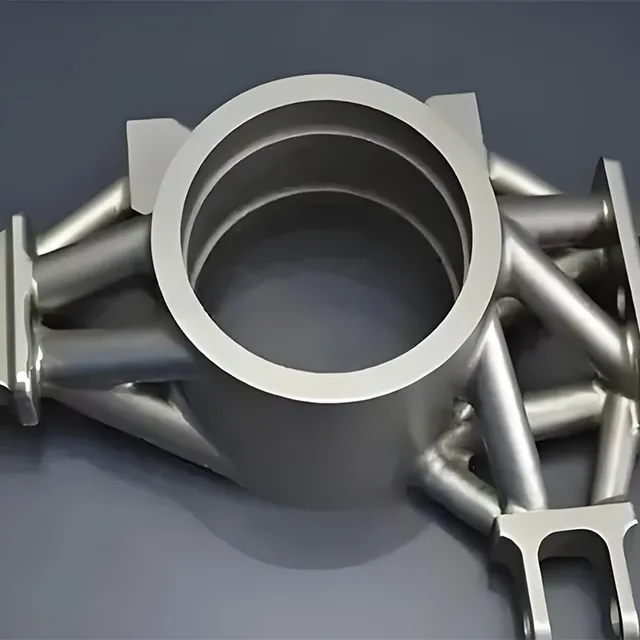

Custom 3D printing Stainless Steel Industrial Manufacture

Place of Origin : Fujian, China

Type : Other Machining Services

Micro Machining or Not : Micro Machining

Model Number : 3D-24

Brand Name : JSD

Product name : Custom 3D Printed Stainless Steel Industrial

Material : Steel

Surface treatment : Painting\Powder Coating\Plating\Polishing

Service : 3D Printed

Color : Customized Color

Size : Customer Size

Tolerance : 0.01- +/-0.005mm

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

MOQ : 1 Piece

Description

Size Details

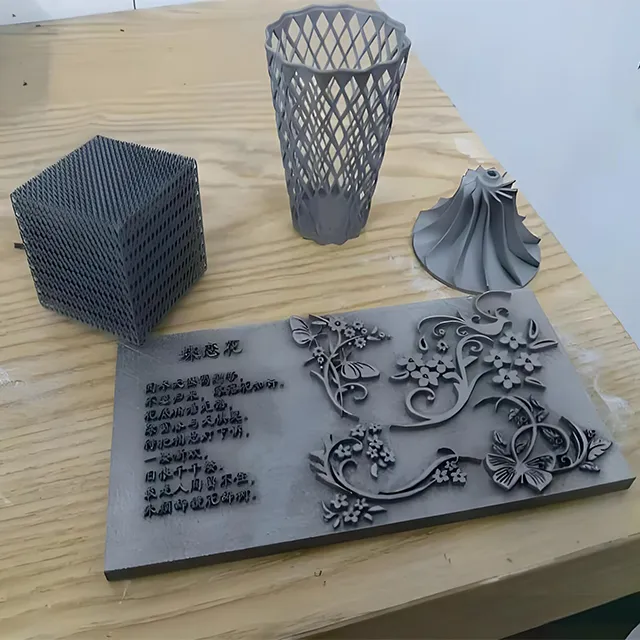

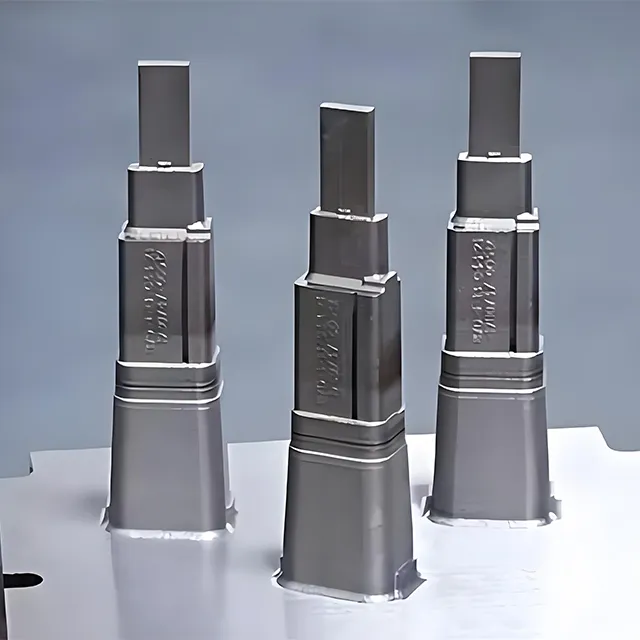

Welcome to the cutting edge of 3D printing technology, we offer a range of high precision, customized stainless steel parts to meet your unique needs in precision machinery, art installations, architectural models and more. Whether you need something as tiny as a precision gear or as massive as a robotic arm assembly, our 3D printing technology can handle it with ease, achieving millimeter or even finer precision control.

Standard sizes: We offer a range of standard sizes of accessories such as bolts, nuts, gears, brackets, etc. for quick selection and replacement.

Customized sizes: With the flexibility of 3D printing, you can design and print accessories of any shape and size to meet your actual needs, enabling a seamless transition from concept to object.

Material Selection

We use high-quality stainless steel materials to ensure that your accessories are not only beautiful and durable, but also able to meet the needs of a variety of harsh working environments.

316L stainless steel: excellent corrosion and high temperature resistance, suitable for marine environments, chemical equipment and medical devices and other scenarios.

17-4 PH stainless steel: high strength, high hardness, suitable for mechanical parts that need to withstand high loads.

304 stainless steel: versatile, with good corrosion resistance, suitable for most indoor and mild outdoor environments.

Application Scenarios

With its unique advantages, 3D printed stainless steel parts are widely used in many fields:

Mechanical industry: customized gears, bearings and connectors to enhance mechanical performance and efficiency.

Aerospace: lightweight and high-strength structural components to meet the needs of complex shapes and lightweight.

Architectural design: artistic sculptures, decorative elements, showing unique design aesthetics.

Medical devices: precision printing of surgical tools and implants to improve medical safety and effectiveness.

Product Advantages

High-precision printing: 3D printing technology ensures the dimensional accuracy and shape consistency of each accessory, reducing assembly errors.

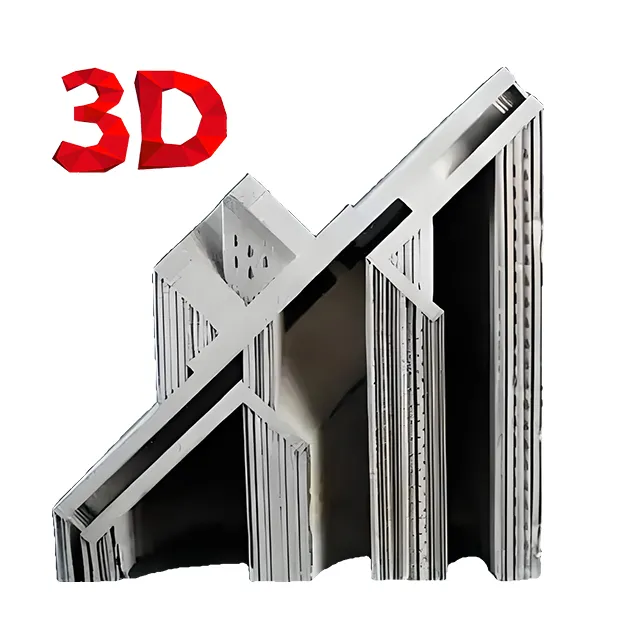

Complex structure realization: No need for molds, easy to print complex internal structures and geometric shapes, reducing design and manufacturing costs.

High Material Utilization: Compared to traditional processing methods, 3D printing reduces material waste and lowers costs.

Rapid Iteration: Rapid transformation from design to finished product accelerates the product development cycle and enhances market competitiveness.

Processing Flow

Demand communication: Through online form or customer service consultation, describe your accessory demand in detail, including size, shape, material, quantity and so on.

3D modeling: Our professional team will perform 3D modeling according to your requirements and provide preview drawings for your confirmation.

Printing Preparation: Choose the most suitable printing strategy and material for pre-printing preparation and debugging.

3D Printing: Adopt advanced SLM (Selective Laser Melting) or SLS (Selective Laser Sintering) technology for high precision printing.

Post-processing: cleaning, de-supporting, surface treatment and other processes are carried out on the finished printed parts to ensure the final quality.

Quality Inspection: Strict quality inspection is carried out to ensure that each accessory meets your requirements.

Packing and shipping: anti-corrosion and shock-proof packaging is used to ensure the safe delivery of the accessories.

Customized Service

Design customization: From conceptual design to finished product, we provide one-stop service to make your idea become reality.

Functional customization: According to specific application scenarios, we customize the functional attributes of the accessories, such as strength, abrasion resistance, corrosion resistance, and so on.

Batch customization: Whether you need one piece or thousands of pieces, we can provide efficient and stable mass production.

3D Printed Stainless Steel Frequently Asked Questions

Q: What is the durability of 3D printed stainless steel parts?

A: The durability of 3D printed stainless steel parts depends on the selected material and post-treatment process. We use high-quality stainless steel materials and undergo strict surface treatment and quality inspection to ensure that the parts have excellent durability.

Q: What is the lead time for customized parts?

A: The lead time depends on the complexity and quantity of the fittings as well as the current production schedule. Generally speaking, it takes about 7-14 working days from design confirmation to finished product delivery. If there is an urgent need, please communicate with us in advance and we will try our best to shorten the lead time.

Q: How can I provide design files?

A: You can send us your design files (e.g. STL, OBJ, etc. format) via e-mail, online file transfer, etc. If you do not have the design files, we will send them to you via e-mail. If you don’t have the design files, our professional designer team can also customize the design according to your needs.

Explore the infinite possibilities of 3D printed stainless steel accessories and make innovative designs a reality. Contact us today to start your customization journey!