Place of Origin : XiaMen, China

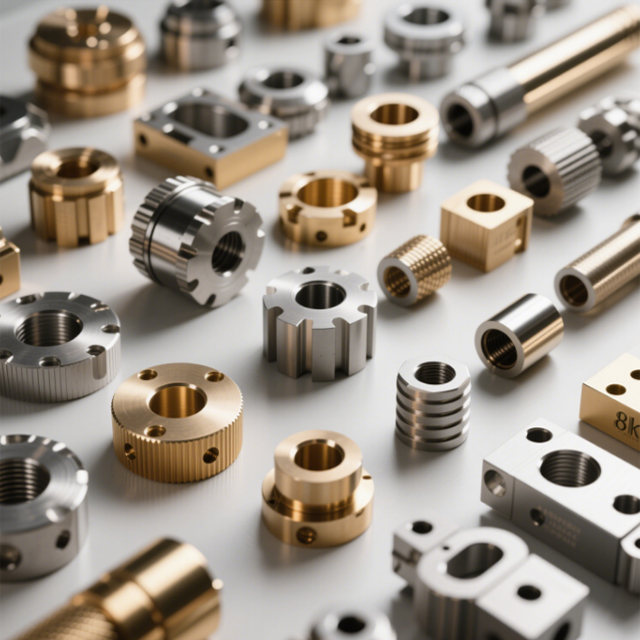

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning

Micro Machining or Not : Micro Machining

Model Number : CNC-07

Brand Name : JSD

Product name : component metal machining parts cnc aluminium

Material : Stainless Steel 304,aluminum,brass

Surface treatment : anodized,electroplating,harden

MOQ : 1pcs

Packing : Customize Package

OEM/ODM : OEM ODM CNC Drilling Milling Machining Service

Logo : Customized Logo

Delivery Time : 15-25 Days

Tolerance : +/-0.005mm