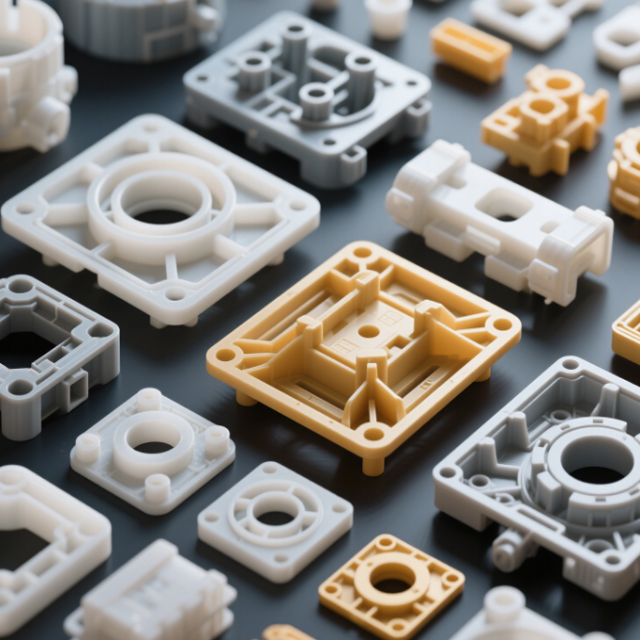

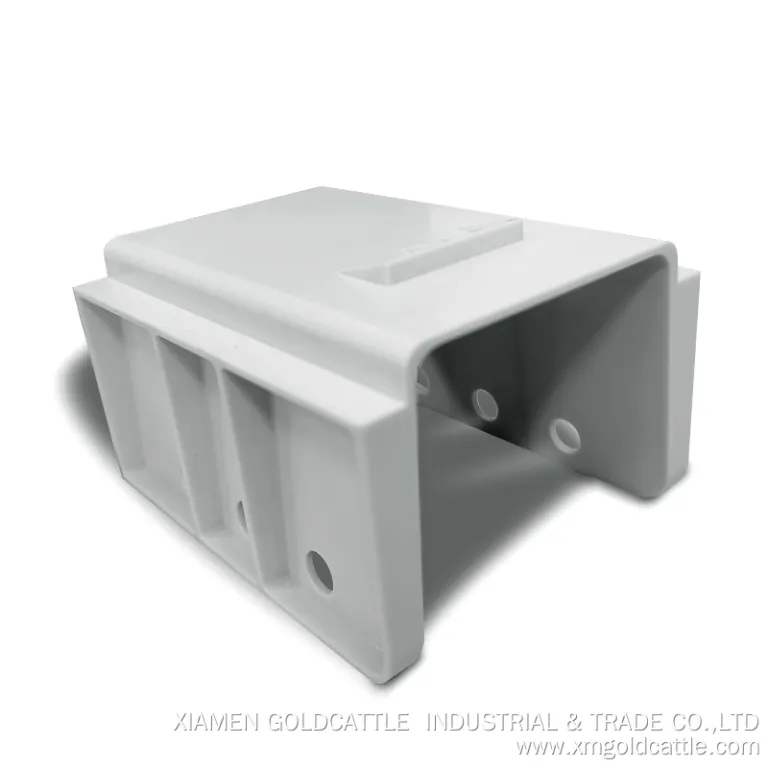

High temperature and chemical resistant Peek plastic parts IM-11

Place of Origin : XiaMen, China

Brand : JSD

Model No. : IM-11

Product Material : Plastic

Service : OEM ODM Customized

Logo : Accept customized logo

Surface Finish : Polished. Etching. Texture

Keyword : Injection Molding Service

Color : Customized color

Mold Material : Engineering Plastic (PEEK/PC/ABS/Nylon)

Material : PEEK/PS/PP/PA/POM/ABS/PC/…