|

Attribute Category

|

Specific Information

|

|

Product Name

|

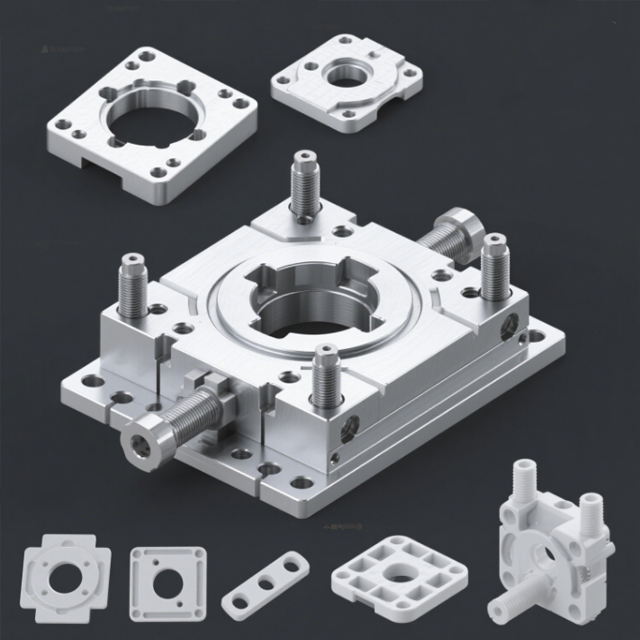

Food Container Injection Mold

|

|

Model Number

|

Customized according to customer needs (e.g., exclusive molds for producing disposable lunch boxes, sauce bottles, plastic storage boxes), etc.

|

|

Application Scope

|

Suitable for producing various food containers, including but not limited to disposable lunch boxes, beverage cups, sauce bottles, plastic storage boxes, food trays, etc.

|

|

Mold Material

|

High-quality mold steel (such as S136, 718H, etc.) is selected, with high strength, high wear resistance, and good corrosion resistance to ensure long-term stable operation of the mold

|

|

Number of Cavities

|

Customizable according to customer production efficiency requirements, from single-cavity to multi-cavity (such as 2-cavity, 4-cavity, 8-cavity, 16-cavity, etc.)

|

|

Mold Size

|

Customized according to the specifications of the produced food containers, covering small, medium, and large molds to meet different production scale requirements

|

|

Precision Level

|

Dimensional accuracy reaches ±0.01mm, ensuring that the produced food containers meet strict specification requirements

|

|

Surface Treatment

|

Processes such as mirror polishing and hard chrome plating are adopted, with surface roughness Ra≤0.05μm, making the surface of food containers smooth and beautiful, and easy to demold

|

|

Production Cycle

|

Conventional mold production cycle is 30-60 days, specifically determined according to mold complexity and customer requirements

|

|

Service Life

|

Under normal use, the mold life can reach more than 500,000 to 1,000,000 cycles

|

|

Heating/Cooling System

|

Equipped with an efficient heating and cooling system, adopting conformal waterway design, with temperature control accuracy of ±1℃ to improve production efficiency and product quality

|

|

Demolding Method

|

Multiple demolding methods such as mechanical demolding and pneumatic demolding are adopted to ensure smooth demolding and reduce product damage

|

|

Quality Certification

|

Passed ISO9001 quality management system certification, compliant with food contact material safety standards (such as FDA, LFGB, etc.)

|