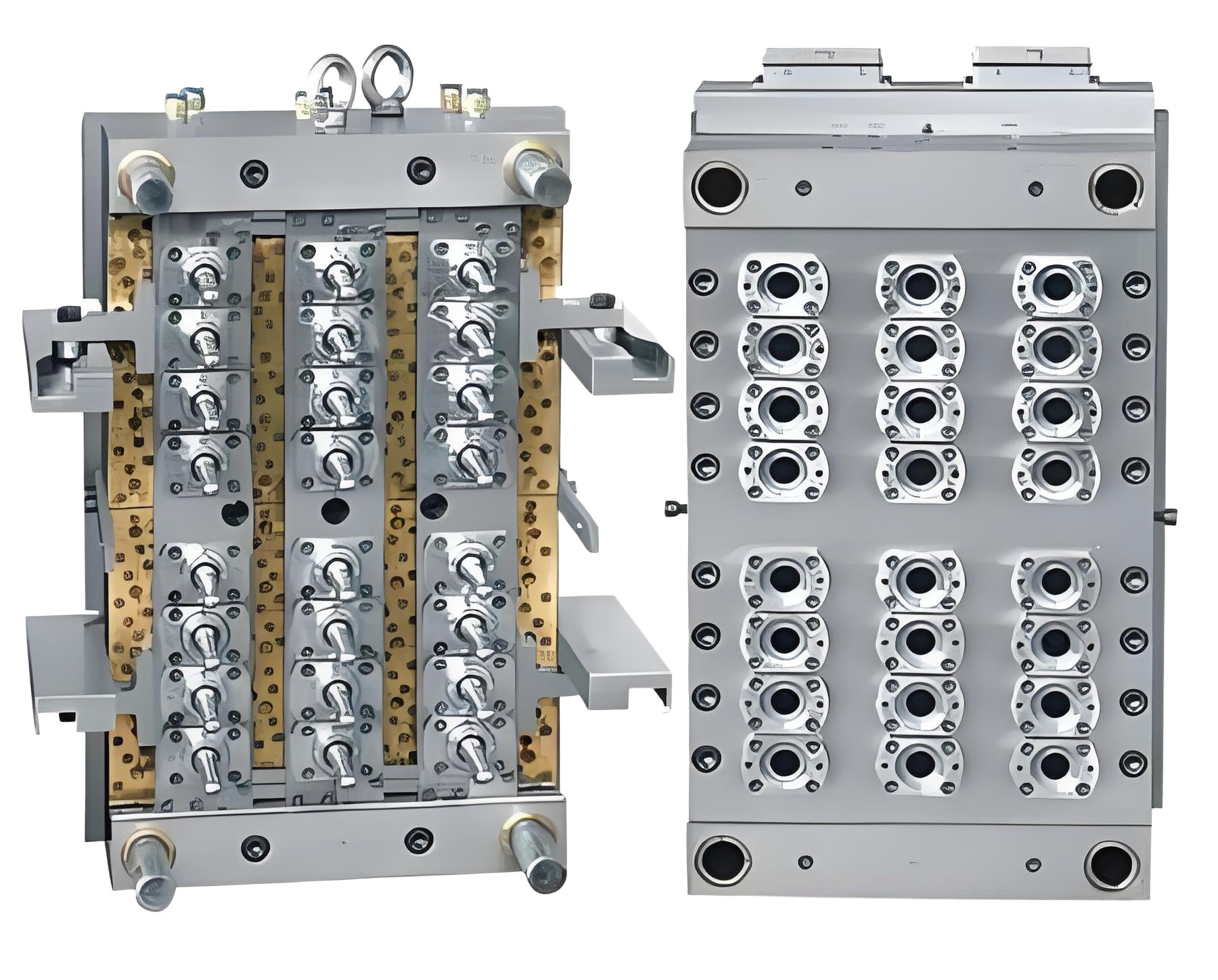

Customized wear-resistant PP injection mold for automotive parts

Place of Origin : XiaMen, China

Model : MJ-06

Keyword : Plastic Injection Molding Service and OEM Assembly

Discription : Custom Plastic Injection Molding Companies Supply Molded Parts

Mold Base : LKM, HASCO, DME or upon customer’s requirement

Mold Life : 50,000 to 1,000,000 shots & custom

Mold Core : 45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc

Production Material : PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc

Mold Cavity : Single or Multiply Cavities

Packaging : Polybag packing or packed according to customer requirement

Transportation : By sea or by air as customer requirement

Main Export Country : USA,UK,Germany,Switzerland,France,Italy,Austrialia and Southeast Asia