Introduction to Rubber Injection Process and Products

Definition and Core Concept

Market Significance

Historical Evolution

- 1839: Charles Goodyear discovers vulcanization process

- 1900s: Development of compression molding for rubber products

- 1950s: Introduction of transfer molding technology

- 1970s: Emergence of rubber injection molding

- 2000s: Integration of automation and Industry 4.0 technologies

Types of Rubber Molding Processes

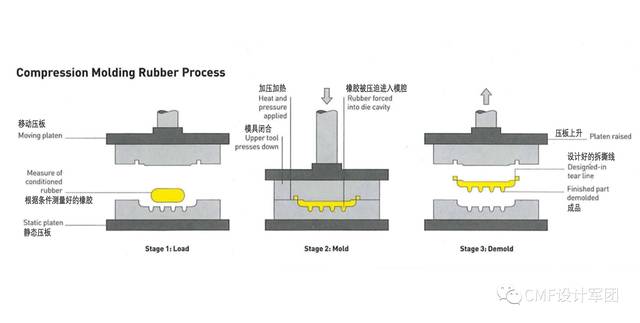

1. Compression Molding

Process Overview

- Pre-forming: Uncured rubber compound is cut into pre-determined shapes (preforms)

- Loading: Preforms are placed into heated mold cavities

- Compression: Mold closes, applying pressure (100-300 MPa) and heat (150-200°C)

- Curing: Rubber vulcanizes for specified time (1-15 minutes)

- Demolding: Mold opens, finished part is removed

Technical Specifications

- Cycle Time: 2-20 minutes per part

- Pressure Range: 10-50 MPa (1,500-7,250 psi)

- Temperature Range: 150-200°C (300-390°F)

- Typical Tolerances: ±0.1-0.5mm

Advantages

- Low Tooling Cost: Simple mold design reduces initial investment

- Material Versatility: Handles high-durometer and specialty compounds

- Minimal Waste: Reduced flash compared to other processes

- Large Part Capability: Suitable for parts up to 1m in diameter

Limitations

- Lower Precision: Less suitable for complex geometries

- Labor Intensive: Manual loading of preforms

- Longer Cycle Times: Slower than injection molding

2. Transfer Molding

Process Principle

Key Features

- Transfer Pot: Holds rubber charge before injection

- Sprues/Runners: Direct material flow to cavities

- Plunger System: Applies pressure to force material flow

- Multi-Cavity Molds: Can produce multiple parts simultaneously

Technical Advantages

- Improved Precision: Better cavity filling than compression molding

- Insert Molding: Accommodates metal/plastic inserts

- Complex Geometries: Produces sharper edges and details

- Consistent Quality: More uniform material distribution

3. Injection Molding

Process Technology

- Material Preparation: Rubber pellets fed into heated barrel

- Plasticization: Screw rotates, heating and mixing rubber (100-150°C)

- Injection: Molten rubber injected into closed mold at high pressure

- Holding Pressure: Maintains pressure during initial curing

- Cooling: Mold remains closed for complete vulcanization

- Ejection: Finished part is automatically ejected

Technical Capabilities

- Cycle Time: 30 seconds to 5 minutes

- Injection Pressure: 50-200 MPa (7,250-29,000 psi)

- Shot Capacity: 50-5,000 grams

- Tolerance Range: ±0.05-0.2mm

Advanced Features

- Closed-Loop Control: Real-time monitoring and adjustment

- Multi-Axis Robotics: Automated part handling

- Vision Systems: In-line quality inspection

- Material Dosing: Precise control of compound feed

Process Comparison

|

Characteristic

|

Compression Molding

|

Transfer Molding

|

Injection Molding

|

|

Cycle Time

|

2-20 minutes

|

1-10 minutes

|

0.5-5 minutes

|

|

Tooling Cost

|

Low ($5,000-20,000)

|

Medium ($15,000-50,000)

|

High ($30,000-150,000)

|

|

Precision

|

Low to Medium

|

Medium to High

|

High to Very High

|

|

Complexity

|

Simple Parts

|

Medium Complexity

|

Complex Geometries

|

|

Volume Suitability

|

Low-Medium

|

Medium-High

|

High-Very High

|

|

Labor Requirement

|

High

|

Medium

|

Low

|

|

Material Waste

|

Low

|

Medium

|

Medium-High

|

Rubber Compound Formulation

Raw Material Components

1. Base Polymer

- Natural Rubber (NR): High elasticity, good fatigue resistance

- Styrene-Butadiene Rubber (SBR): Good wear resistance, low cost

- Nitrile Rubber (NBR): Excellent oil and fuel resistance

- Ethylene Propylene Diene Monomer (EPDM): Superior weathering resistance

- Silicone Rubber (VMQ): Wide temperature range, biocompatibility

2. Vulcanizing Agents

- Sulfur: Primary curing agent for most diene rubbers

- Peroxides: Used for saturated rubbers like EPDM and silicone

- Metal Oxides: Zinc oxide and magnesium oxide as activators

- Accelerators: Speed up vulcanization (MBTS, CBS, TMTD)

3. Fillers and Reinforcements

- Carbon Black: Improves strength, wear resistance, and UV protection

- Silica: Enhances tear strength and reduces heat buildup

- Clay: Cost-effective filler for general-purpose compounds

- Calcium Carbonate: Improves processing and reduces cost

4. Processing Aids

- Plasticizers: Improve flow and processability

- Lubricants: Reduce friction during mixing and molding

- Antidegradants: Protect against oxidation, ozone, and UV damage

- Colorants: Provide aesthetic appeal and identification

Compound Development Process

- Material Selection: Based on application requirements

- Formulation Design: Determining optimal component ratios

- Laboratory Testing: Evaluating uncured and cured properties

- Pilot Production: Scaling up to production quantities

- Quality Validation: Ensuring consistency and performance

Material Properties and Selection

Temperature Resistance

- Low Temperature: Natural rubber (-50°C), silicone (-60°C)

- High Temperature: Silicone (200°C), fluorocarbon rubber (250°C)

Chemical Resistance

- Oils/Fuels: Nitrile rubber, hydrogenated nitrile

- Acids/Alkalis: EPDM, fluorocarbon rubber

- Solvents: Fluorocarbon rubber, chlorosulfonated polyethylene

Mechanical Properties

- Tensile Strength: Natural rubber (25-35 MPa), silicone (5-10 MPa)

- Elongation: Natural rubber (700-800%), EPDM (300-500%)

- Hardness: 30-90 Shore A scale

The Manufacturing Process

Process Starts: Preparation Phase

1. Material Preparation

- Compounding: Mixing base polymer with additives in Banbury mixer

- Milling: Further mixing and homogenization on two-roll mill

- Sheeting: Forming into sheets for compression molding

- Pelletizing: Producing pellets for injection molding

2. Mold Design and Fabrication

- CAD Modeling: Designing mold cavities and cores

- CNC Machining: Precision manufacturing of mold components

- Heat Treatment: Hardening mold surfaces (50-60 HRC)

- Surface Finishing: Polishing to achieve desired surface quality

3. Machine Setup

- Temperature Calibration: Setting mold and barrel temperatures

- Pressure Adjustment: Configuring hydraulic systems

- Cycle Programming: Setting time parameters for each stage

- Safety Checks: Verifying all safety interlocks

Heating the Rubber

Temperature Control Systems

- Electric Heaters: For precise temperature regulation

- Oil Heating: For uniform heat distribution

- Steam Heating: Traditional method for large molds

- Induction Heating: Modern, energy-efficient technology

Vulcanization Chemistry

- Scorch Delay: Initial heating without cross-linking

- Cure Initiation: Cross-linking reactions begin

- Cure Acceleration: Rapid cross-link formation

- Cure Completion: Optimal cross-link density achieved

- Overcure: Degradation of properties if heated too long

Temperature Profiles

- Compression Molding: 150-180°C (300-355°F)

- Transfer Molding: 160-190°C (320-375°F)

- Injection Molding: 170-200°C (340-390°F)

Heat and Pressure Application

Pressure Requirements

- Compression Force: 10-50 MPa (1,500-7,250 psi)

- Injection Pressure: 50-200 MPa (7,250-29,000 psi)

- Clamping Force: Determined by projected area and pressure

Pressure Distribution

- Uniform Pressure: Critical for consistent part quality

- Pressure Sensors: Monitoring and controlling pressure levels

- Pressure Regulation: Adjusting for different material viscosities

Thermal Management

- Heat Uniformity: Ensuring consistent temperature across mold

- Cooling Systems: Controlling post-cure cooling rate

- Energy Efficiency: Optimizing heating and cooling cycles

Complete Process Flow

- Material Loading → 2. Heating and Plasticization → 3. Injection/Filling → 4. Holding Pressure → 5. Vulcanization → 6. Cooling → 7. Demolding → 8. Finishing → 9. Inspection → 10. Packaging

Molded Rubber Parts and Applications

Automotive Industry

Key Applications

- Sealing Systems: Door seals, window seals, weatherstripping

- Vibration Control: Engine mounts, suspension bushings, shock absorbers

- Fluid Handling: Fuel hoses, coolant hoses, brake lines

- Electrical Components: Gaskets, connectors, insulation parts

Technical Requirements

- Temperature Resistance: -40°C to +150°C for underhood applications

- Chemical Resistance: Oils, fuels, coolants, and road salts

- Durability: 10+ years of service life

- Precision: Tight tolerances for proper fit and function

Aerospace and Defense

Critical Components

- Sealing Systems: Aircraft door seals, window seals, fuel system seals

- Fluid Transfer: Hydraulic hoses, fuel lines, pneumatic components

- Vibration Isolation: Engine mounts, avionics isolation systems

- Thermal Protection: High-temperature gaskets and seals

Performance Standards

- MIL-Specifications: Meeting military performance requirements

- FAA Certification: Compliance with aviation safety standards

- Extreme Temperatures: -65°C to +260°C for certain applications

- Fire Resistance: Self-extinguishing materials for cabin safety

Medical and Healthcare

Medical-Grade Rubber

- Silicone Rubber: Biocompatible, sterilizable, wide temperature range

- EPDM: Excellent weathering resistance for medical devices

- Natural Rubber: High elasticity for surgical gloves

- TPEs: Thermoplastic elastomers for disposable devices

Regulatory Compliance

- FDA Approval: Food and Drug Administration requirements

- ISO 10993: Biocompatibility testing standards

- USP Class VI: Plastic classification for medical devices

- CE Marking: Conformité Européene for European market

Industrial and Manufacturing

Heavy-Duty Applications

- Industrial Seals: Hydraulic seals, pneumatic seals, shaft seals

- Conveyor Systems: Rollers, belts, wear strips

- Mining Equipment: Hoses, gaskets, vibration isolators

- Oil and Gas: Downhole seals, drilling components

Performance Requirements

- Abrasion Resistance: Extended service life in harsh environments

- Chemical Compatibility: Resistance to industrial fluids and solvents

- Pressure Ratings: High-pressure applications up to 100 MPa

- Temperature Extremes: -50°C to +200°C operation

High Volume Production Capabilities

Production Scales and Capacities

Low Volume (100-10,000 parts/year)

- Suitable Processes: Compression molding, small-batch injection

- Lead Time: 2-4 weeks

- Cost Structure: Higher unit cost, lower tooling investment

- Flexibility: Easy design changes and material modifications

Medium Volume (10,000-100,000 parts/year)

- Suitable Processes: Transfer molding, automated compression

- Lead Time: 4-8 weeks

- Cost Structure: Balanced tooling and production costs

- Efficiency: Good balance of automation and flexibility

High Volume (100,000+ parts/year)

- Suitable Processes: Injection molding, multi-cavity tools

- Lead Time: 8-16 weeks

- Cost Structure: Lower unit cost, higher tooling investment

- Automation: Fully automated production lines

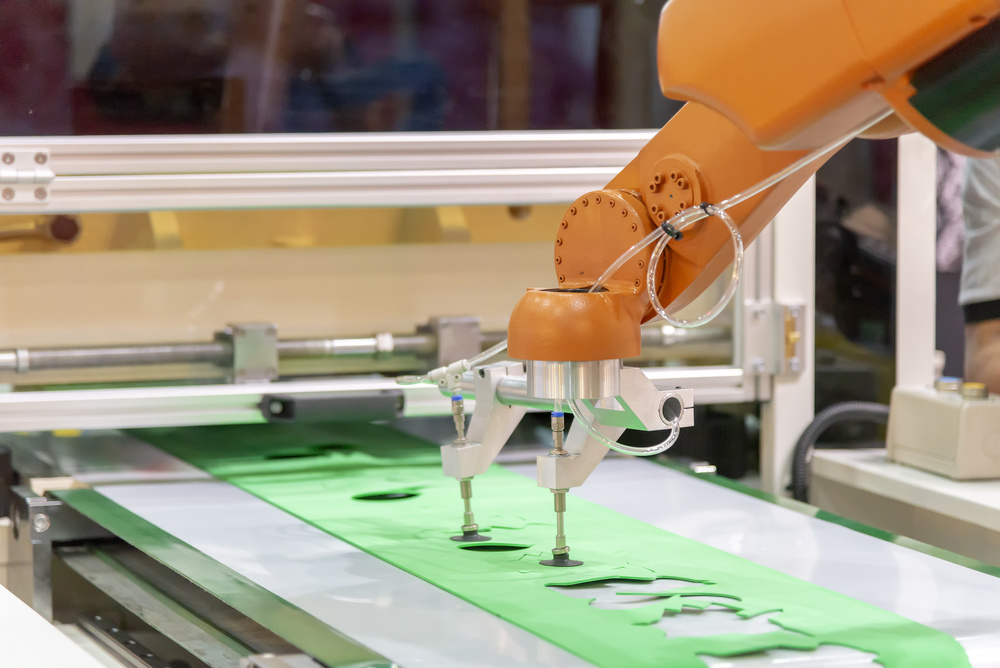

Automation Technologies

Material Handling

- Robot Loading: Automated feeding of rubber compounds

- Conveyor Systems: Continuous material transport

- Automatic Weighing: Precise material dosing

- Material Drying: Controlled moisture management

Process Automation

- PLC Control: Programmable logic controllers for process management

- HMI Interfaces: User-friendly operator interfaces

- Data Acquisition: Real-time process monitoring

- Remote Monitoring: Overseeing operations from central control room

Quality Assurance

- Vision Inspection: Automated defect detection

- In-line Testing: Real-time quality verification

- Statistical Process Control: Quality trend analysis

- Traceability Systems: Complete product genealogy

Production Efficiency Metrics

Equipment Efficiency

- OEE (Overall Equipment Effectiveness): >85% for world-class operations

- Cycle Time: Optimized for maximum throughput

- Downtime: Minimized through preventive maintenance

- Changeover Time: Reduced with quick-change tooling

Quality Metrics

- First Pass Yield: >95% for mature processes

- Defect Rate: <0.5% for high-volume production

- Customer Rejects: <0.1% for quality leaders

- On-time Delivery: >98% for reliable suppliers

Quality Control and Testing Standards

ASTM Standards

- ASTM D575: Standard Test Methods for Rubber Properties in Compression

- ASTM D412: Tensile Properties of Vulcanized Rubber and Thermoplastic Elastomers

- ASTM D2240: Standard Test Method for Rubber Property—Durometer Hardness

- ASTM D624: Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

ISO Standards

- ISO 37: Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties

- ISO 48: Rubber, vulcanized or thermoplastic — Determination of hardness

- ISO 34-1: Rubber, vulcanized or thermoplastic — Determination of tear strength

- ISO 815: Rubber, vulcanized or thermoplastic — Determination of compression set

Industry-Specific Standards

- SAE J200: Rubber Products—Automotive Applications

- MIL-SPEC: Military specifications for defense applications

- FDA 21 CFR: Food contact and medical applications

- REACH: European chemical regulations

Testing Methods and Equipment

Mechanical Testing

- Tensile Testing: Measuring strength and elongation

- Hardness Testing: Shore A and Shore D durometers

- Compression Testing: ASTM D575 procedures

- Tear Testing: Measuring resistance to tearing

Environmental Testing

- Temperature Testing: Thermal chambers for extreme conditions

- Weathering Testing: UV exposure and ozone resistance

- Chemical Resistance: Immersion in various fluids

- Aging Testing: Accelerated life testing

Dimensional Inspection

- Coordinate Measuring Machines (CMM): 3D measurement of complex parts

- Optical Comparators: 2D profile measurement

- Laser Scanning: Non-contact surface measurement

- Vision Systems: Automated dimensional verification

Quality Management Systems

ISO 9001 Certification

- Process Documentation: Standard operating procedures

- Training Programs: Operator qualification and certification

- Internal Audits: Regular quality system reviews

- Continuous Improvement: Kaizen and Six Sigma methodologies

Statistical Process Control

- Control Charts: Monitoring process variation

- Capability Analysis: Cp and Cpk calculations

- Defect Tracking: Root cause analysis and corrective actions

- Preventive Maintenance: Scheduled equipment servicing

Industry Trends and Market Outlook

Technological Advancements

Industry 4.0 Integration

- Smart Manufacturing: IoT-connected production equipment

- Big Data Analytics: Predictive maintenance and quality control

- Digital Twin: Virtual simulation of production processes

- Additive Manufacturing: 3D printing of rubber prototypes

Material Innovations

- Bio-based Rubbers: Sustainable alternatives to petroleum-based products

- Self-healing Materials: Rubber compounds that repair damage

- Conductive Rubbers: For EMI shielding and sensor applications

- Shape Memory Polymers: Smart materials with programmable properties

Process Improvements

- In-Mold Sensors: Real-time process monitoring

- Rapid Heating/Cooling: Reduced cycle times

- Micro-Molding: Precision molding of micro-components

- Multi-Material Molding: Combining different rubber compounds

Market Growth Drivers

Automotive Electrification

- EV Components: Battery seals, charging system components

- Lightweighting: Reduced weight for improved efficiency

- Thermal Management: Heat-resistant materials for electronics

- Noise Reduction: Enhanced NVH (Noise, Vibration, Harshness) solutions

Healthcare Expansion

- Medical Devices: Growing demand for diagnostic and therapeutic equipment

- Aging Population: Increased need for medical products and mobility aids

- Home Healthcare: Portable medical devices requiring durable components

- Biomedical Engineering: Advanced materials for implants and prosthetics

Infrastructure Development

- Construction Boom: Sealing systems for buildings and infrastructure

- Renewable Energy: Rubber components for wind turbines and solar installations

- Water Management: Seals and gaskets for water treatment facilities

- Transportation Networks: Expansion of rail and public transit systems

Sustainability Initiatives

Green Manufacturing

- Energy Efficiency: Reduced energy consumption in production

- Waste Reduction: Minimizing material scrap and packaging waste

- Recycling Programs: Closed-loop systems for rubber waste

- Carbon Footprint: Measuring and reducing greenhouse gas emissions

Sustainable Materials

- Recycled Rubber: Using reclaimed rubber in new products

- Bio-based Polymers: Rubber derived from renewable resources

- Degradable Materials: Environmentally friendly end-of-life solutions

- Carbon Neutrality: Achieving net-zero carbon emissions

Frequently Asked Questions

Q1: What factors determine the choice of rubber molding process?

- Part Complexity: Simple parts suit compression molding; complex parts require injection molding

- Production Volume: Low volume favors compression; high volume benefits from injection

- Precision Requirements: Tight tolerances require injection or transfer molding

- Material Type: High-durometer compounds often use compression molding

- Budget Constraints: Tooling cost and production efficiency considerations

Q2: How long does the rubber molding process take?

- Compression Molding: 2-20 minutes per part

- Transfer Molding: 1-10 minutes per part

- Injection Molding: 30 seconds to 5 minutes per part

Q3: What is the typical cost of rubber molding tooling?

- Compression Molds: (5,000-)20,000

- Transfer Molds: (15,000-)50,000

- Injection Molds: (30,000-)150,000+

Q4: How to ensure consistent quality in rubber molding?

- Process Control: Monitoring temperature, pressure, and time

- Material Testing: Verifying compound properties before molding

- In-line Inspection: Checking dimensions and visual defects

- Statistical Methods: Using SPC to monitor process variation

- Operator Training: Ensuring proper machine operation

Q5: What are the environmental considerations in rubber molding?

- Energy Consumption: Optimizing heating and cooling cycles

- Volatile Organic Compounds (VOCs): Controlling emissions during vulcanization

- Waste Management: Recycling scrap rubber and packaging

- Sustainable Materials: Using bio-based and recycled rubber compounds

- Carbon Footprint: Measuring and reducing greenhouse gas emissions