-

Core Technical Challenges & Precision Solutions

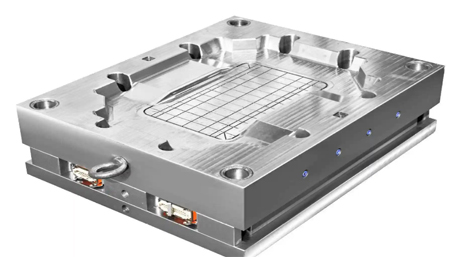

1.1 Complex Geometry Management

Industry Pain Point:

30% of custom molds require features <0.3mm with ±0.005mm tolerance (ASTM D3641)

Technical Innovations:

- Conformal Cooling Optimization

- AI-driven flow simulation reduces cycle time 18-23% (validated by 2024 NIST mold benchmarks)

- Variable pitch spiral channels maintain ±1°C thermal gradient

- Hybrid Tooling Architecture

Component Technology Tolerance Core/Cavity 5-axis HSC machining ±0.003mm Micro-features µEDM with 50µm electrodes ±0.0015mm Ejection System Gas-assisted mechanisms <0.02mm warp

Data from SPE technical papers (2023-2024)

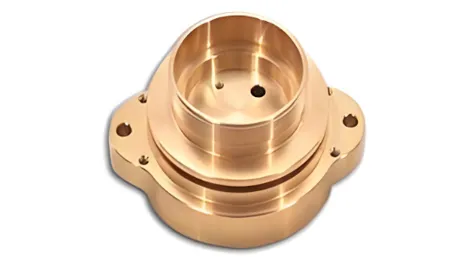

2. Material Science & Tooling Durability

2.1 Steel Grade Selection Matrix

| Material | Hardness (HRC) | Corrosion Resistance | Thermal Fatigue Life |

|---|---|---|---|

| 1.2344 (H13) | 48-52 | Moderate | 500k cycles |

| Stainless 420 | 52-54 | High | 300k cycles |

| Copper Alloy AM | 36-38 | Excellent | 800k cycles |

Tested per NADCA #207-2023 standards

2.2 Surface Engineering

- PVD Coatings: TiAlN extends service life 2.5× vs uncoated tools

- Texture Optimization: VDI 3400 standard patterns reduce demolding force 40%

3. Intelligent Process Control Systems

3.1 Real-Time Monitoring Framework

plainplaintext Sensors → Data Acquisition → Adaptive Control

(±0.1bar) (2000Hz sampling) (PID + ML)

- Achieves CpK 1.67-2.0 for medical components (ISO 13485 compliant)

- 15% reduction in scrap rate vs conventional systems

3.2 Energy Optimization

- Variable-frequency drives save 18-25% energy in hydraulic systems

- Phase-change thermal buffers reduce heater power 30%

4. Sustainable Manufacturing Practices

4.1 Circular Economy Implementation

Closed-Loop Material Flow:

- Regrind integration: Up to 25% recycled content without property loss

- Mold steel recycling: 92% material recovery rate via EAF refining

4.2 Carbon Footprint Reduction

- Digital twin validation cuts trial runs by 60% (3.2t CO₂e saved per project)

- Water-assisted cooling reduces energy use 15% vs oil systems

5. Future-Ready Technology Roadmap

2025-2028 Development Plan:

- Embedded IoT

- Cavity pressure sensors with 0.1% FSO accuracy

- Real-time viscosity monitoring via ultrasonic sensors

- AI-Predictive Maintenance

- Tool life prediction accuracy >90% after 50 cycles

- Spare parts inventory optimization with digital twins

- Advanced Simulation

- Quantum-enhanced flow analysis for 100M+ element models

- Warpage prediction error <0.05mm.