Yes, 3D printers can print metal—but only with specialized metal 3D printers (not consumer-grade FDM/PLA printers). These printers use advanced technologies to melt, fuse, or bind metal materials (powders, wires) into solid parts, and are widely used in industrial, medical, and aerospace fields.

However, metal 3D printing has clear technical boundaries: it’s not a “one-size-fits-all” solution—different metal 3D printing technologies (e.g., SLM, DMLS) excel at different materials (titanium, stainless steel) and applications (medical implants, aerospace parts). Below, we’ll break down everything you need to know, from how it works to real-world use cases.

1. How Metal 3D Printers Work: Key Technologies Explained

Metal 3D printing is not a single process but a set of layer-based manufacturing techniques. The core difference between technologies lies in “how metal materials are fused into layers.” Here’s a detailed breakdown of 4 mainstream methods (with long-tail keyword integration):

1.1 Selective Laser Melting (SLM): The Go-To for Industrial Metal 3D Printing

- Full Name: Selective Laser Melting (SLM)

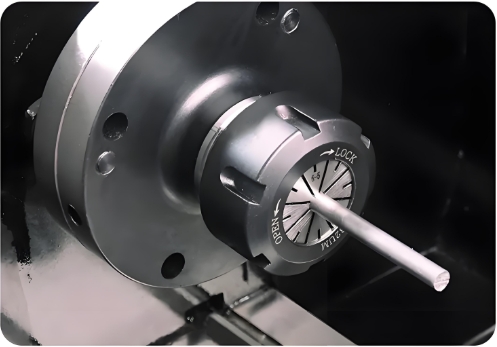

- Core Principle: A high-power fiber laser (500–1000W) selectively melts a bed of metal powder (layer thickness: 20–100μm). After each layer is melted, the build platform lowers by one layer height, and new powder is spread—repeating until the part is complete. Laser energy density (typically 100–500 J/mm³) must be precisely controlled to ensure full powder melting without cracking.

- Suitable Materials: Titanium alloy (Ti-6Al-4V), stainless steel (316L, 17-4PH), aluminum alloy (AlSi10Mg), cobalt-chromium alloy (CoCrMo).

- Accuracy & Surface Quality: Dimensional accuracy ±0.1mm (for 100mm parts); surface roughness Ra 6.3–12.5μm (requires post-processing to polish to Ra 0.8μm).

- Typical Applications: Aerospace lightweight components (e.g., satellite brackets), medical implants (e.g., artificial joints), high-precision mold inserts.

- Long-Tail Keywords: SLM metal 3D printing principle, industrial metal 3D printing technology, titanium alloy 3D printing process.

1.2 Direct Metal Laser Sintering (DMLS): Ideal for Alloys & Composites

- Full Name: Direct Metal Laser Sintering (DMLS)

- Core Principle: Similar to SLM, but the laser only “sinters” metal powder (heats it to near-melting point for particle bonding) instead of full melting. As a result, part density is slightly lower than SLM (DMLS: 95–98%; SLM: 99.5%+).

- Key Difference: DMLS can print mixed powders (e.g., metal-ceramic composites) and has looser powder particle size requirements (5–45μm vs. SLM’s 15–45μm).

- Suitable Materials: Tool steel (H13), nickel-based superalloy (Inconel 718), copper alloy (CuCrZr).

- Typical Applications: Heat-resistant automotive engine parts (e.g., turbocharger blades), electronic heat sinks (copper alloy).

- Long-Tail Keywords: DMLS metal 3D printing technology, nickel-based alloy 3D printing method, copper alloy 3D printing process.

1.3 Electron Beam Melting (EBM): For High-Temperature & Large-Size Parts

- Full Name: Electron Beam Melting (EBM)

- Core Principle: Uses an electron beam (instead of a laser) as the energy source to melt metal powder in a vacuum environment. The vacuum prevents metal oxidation (ideal for oxidizable materials like titanium and tantalum), and the electron beam’s higher energy enables melting of high-melting-point metals.

- Pros & Cons: Pros include faster printing speed (30% faster than SLM) and lower part internal stress; cons include lower accuracy (±0.2mm) and large equipment size (only suitable for large parts).

- Suitable Materials: Titanium alloy (Ti-6Al-4V ELI, medical grade), tantalum (Ta), tungsten (W, high-melting-point metal).

- Typical Applications: Large medical implants (e.g., spinal fusion cages), aerospace engine combustion chambers.

- Long-Tail Keywords: EBM metal 3D printing technology, high-melting-point metal 3D printing method, large metal part 3D printing.

1.4 Binder Jetting: A Low-Cost Metal 3D Printing Option

- Full Name: Binder Jetting (BJ)

- Core Principle: Similar to FDM, but the printer head ejects “binder” (instead of plastic filament) to bond metal powder layer-by-layer into a “green part.” Post-processing—debinding (removing binder) and sintering (high-temperature fusing of metal particles)—is required to produce the final metal part.

- Pros & Cons: Pros include low equipment cost (1/3 of SLM) and fast printing speed; cons include long post-processing cycles (24–48 hours) and lower part strength (suitable for non-load-bearing parts).

- Suitable Materials: Stainless steel (316L), iron-based alloys (e.g., 4140 steel), bronze (CuSn10).

- Typical Applications: Decorative metal parts (e.g., custom badges), low-load industrial components (e.g., sensor housings).

- Long-Tail Keywords: Binder jetting metal 3D printing, low-cost metal 3D printing technology, stainless steel 3D printing process.

2. Metal 3D Printing Materials: Types, Properties & Use Cases

Not all metals are suitable for 3D printing—they must meet criteria like “good powder flowability” and “melting point compatibility with the technology.” Below are 6 mainstream metal 3D printing materials and their applications (with long-tail keywords):

2.1 Titanium Alloy (Ti-6Al-4V): Top Choice for Medical & Aerospace

- Properties: Low density (4.51 g/cm³), high strength (tensile strength: 900 MPa), excellent biocompatibility (no rejection), and strong corrosion resistance (suitable for harsh environments).

- Technology Compatibility: SLM, EBM (vacuum environment prevents oxidation).

- Typical Applications: Medical implants (artificial hips, dental implants), aerospace components (drone fuselage frames).

- Long-Tail Keywords: Titanium alloy 3D printing material, medical-grade metal 3D printing material, aerospace metal 3D printing material.

2.2 Stainless Steel (316L/17-4PH): Common for Industrial Parts & Molds

- Properties: 316L offers strong corrosion resistance (suitable for outdoor/marine environments); 17-4PH has high hardness (HRC 40–45, ideal for wear-resistant parts).

- Technology Compatibility: SLM, DMLS, Binder Jetting.

- Typical Applications: Food machinery parts (316L, corrosion-resistant), mold inserts (17-4PH, wear-resistant), chemical equipment components.

- Long-Tail Keywords: Stainless steel 3D printing material, 316L metal 3D printing, wear-resistant metal 3D printing part.

2.3 Aluminum Alloy (AlSi10Mg): Cost-Effective for Lightweight Parts

- Properties: Low density (2.68 g/cm³), good thermal conductivity, and low cost (1/5 of titanium alloy)—suitable for lightweight non-load-bearing parts.

- Technology Compatibility: SLM (requires high-power laser to prevent aluminum powder oxidation).

- Typical Applications: Automotive lightweight parts (e.g., battery trays), electronic device housings (e.g., 5G base station heat sinks).

- Long-Tail Keywords: Aluminum alloy 3D printing material, lightweight metal 3D printing part, electronic heat dissipation metal 3D printing.

2.4 Nickel-Based Superalloy (Inconel 718): For High-Temperature Environments

- Properties: High-temperature resistance (long-term operating temperature: 650°C), strong fatigue resistance, and oxidation corrosion resistance—ideal for extreme environments.

- Technology Compatibility: DMLS, SLM.

- Typical Applications: Aerospace engine parts (e.g., turbine blades), nuclear energy equipment components (e.g., reactor brackets).

- Long-Tail Keywords: Nickel-based superalloy 3D printing, high-temperature metal 3D printing material, aerospace engine metal 3D printing part.

2.5 Copper Alloy (CuCrZr): Key Material for High Thermal Conductivity

- Properties: High thermal conductivity (350 W/m·K, 5x that of stainless steel) and good electrical conductivity, but high reflectivity (low laser absorption—requires special treatment).

- Technology Compatibility: DMLS (laser wavelength tuned to 1064nm to improve absorption).

- Typical Applications: Electronic heat dissipation components (e.g., CPU water cooling blocks), new energy vehicle motor windings.

- Long-Tail Keywords: Copper alloy 3D printing material, high thermal conductivity metal 3D printing part, electronic heat dissipation 3D printing solution.

2.6 Cobalt-Chromium Alloy (CoCrMo): Ideal for Biomedical & Wear-Resistant Parts

- Properties: Excellent biocompatibility (suitable for long-term human implantation), high hardness (HRC 35–40), and strong wear resistance—ideal for dentistry and orthopedics.

- Technology Compatibility: SLM.

- Typical Applications: Dental crowns/bridges (tooth restoration), artificial knee femoral components, prosthetic joints.

- Long-Tail Keywords: Cobalt-chromium alloy 3D printing material, dental metal 3D printing material, biomedical metal 3D printing part.

3. Applications of Metal 3D Printing: Real-World Cases Across Industries

The core advantages of metal 3D printing—“complex structure manufacturing” and “high material utilization”—have made it integral to high-value industries (with long-tail keywords):

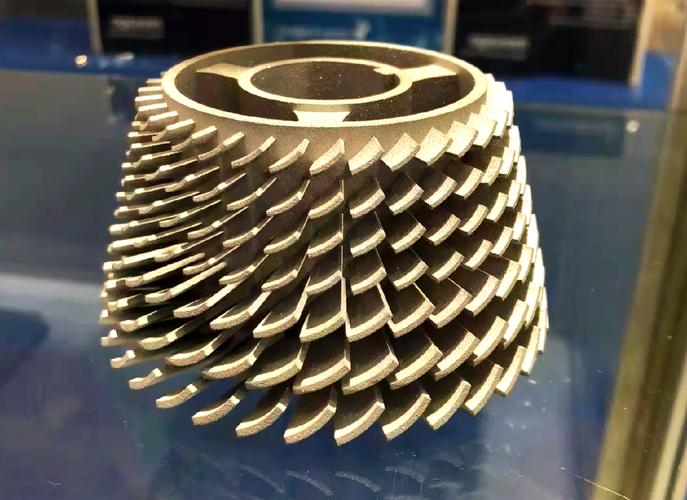

3.1 Aerospace: Metal 3D Printing for Lightweight Components

- Pain Point: Traditional manufacturing (forging, milling) struggles with complex hollow structures, leading to heavy parts and high material waste (up to 80%).

- 3D Printing Solution: SLM-printed titanium alloy lightweight parts, such as:

-

- Airbus A350 satellite brackets: 30% weight reduction, material utilization increased from 20% to 95%.

-

- SpaceX Dragon spacecraft engine combustion chambers: Integrated printing, reducing 50 welding points.

- Long-Tail Keywords: Aerospace metal 3D printing application, metal 3D printing lightweight part, satellite bracket 3D printing case.

3.2 Medical: Custom Metal 3D Printed Implants

- Pain Point: Traditional implants (e.g., artificial joints) are one-size-fits-all, failing to match patients’ anatomical structures and leading to high post-operative complication rates.

- 3D Printing Solution: EBM-printed custom titanium alloy implants using patient CT scan data, such as:

-

- Spinal fusion cages: Tailored to the patient’s spinal curve, increasing fusion success rate by 25%.

-

- Dental implants: Matched to alveolar bone density, reducing bone resorption risk.

- Long-Tail Keywords: Medical metal 3D printing application, custom metal implant 3D printing, titanium alloy artificial joint 3D printing case.

3.3 Automotive: Metal 3D Printing for High-Performance & Custom Parts

- Pain Point: High-performance sports cars require small-batch complex parts (e.g., turbochargers) with high traditional mold costs (>¥100,000); new energy vehicles need lightweight components to reduce energy consumption.

-

- Porsche 911 GT2 RS turbocharger blades: DMLS-printed Inconel 718, increasing high-temperature resistance by 15%.

-

- Tesla 4680 battery structural parts: Binder Jetting-printed stainless steel, improving production line efficiency by 40%.

- Long-Tail Keywords: Automotive metal 3D printing application, new energy vehicle metal 3D printing part, turbocharger 3D printing case.

3.4 Mold Manufacturing: Rapid Custom Mold Inserts via Metal 3D Printing

- Pain Point: Traditional mold inserts require CNC milling, making complex cooling channels hard to machine—leading to uneven injection molding cooling and long production cycles.

- 3D Printing Solution: SLM-printed 17-4PH stainless steel mold inserts with conformal cooling channels (matching the shape of injection-molded parts), such as:

-

- Mobile phone case molds: Cooling time reduced from 20s to 8s, improving production efficiency by 60%.

-

- Home appliance part molds: Reducing injection molding warpage, increasing qualification rate from 85% to 98%.

- Long-Tail Keywords: Mold metal 3D printing application, metal 3D printing mold insert, conformal cooling channel 3D printing case.

4. Pros & Cons of Metal 3D Printing: Cost, Accuracy & Limitations (with Long-Tail Keywords)

Metal 3D printing is not perfect—trade-offs are necessary based on needs. Below is a detailed analysis:

4.1 Pros of Metal 3D Printing: Why Choose This Technology?

- 1. Complex Structure Manufacturing Capability: Can print structures impossible with traditional processes (e.g., hollow lattices, internal flow channels) without assembly—reducing part count (e.g., an aerospace part integrated from 10 components, cutting assembly costs by 70%).

- 2. High Material Utilization: Traditional milling wastes up to 80% of material, while metal 3D printing achieves 90%+ utilization (powders are recyclable, with 70–80% recovery rate)—ideal for expensive metals (e.g., titanium alloy).

- 3. Low Customization Cost: No molds required for small-batch production (1–100 parts), with costs 1/3 of traditional processes (e.g., custom medical implants: ¥50,000 mold cost for traditional manufacturing vs. no mold cost for 3D printing).

- 4. Controllable Part Performance: Adjusting process parameters (e.g., laser power, layer thickness) optimizes part density (95–99.9%) and hardness (HRC 30–50) to meet different strength requirements.

- Long-Tail Keywords: Metal 3D printing advantage, complex structure metal 3D printing, metal 3D printing material utilization.

4.2 Cons of Metal 3D Printing: Which Scenarios Are Not Suitable?

- 1. High Equipment & Material Costs: Industrial SLM equipment costs ¥1–5 million; metal powder costs ¥500–5,000/kg (titanium alloy powder: ¥5,000/kg, 10x that of stainless steel)—not suitable for low-cost mass production (>1,000 parts; traditional forging is recommended).

- 2. Slow Printing Speed: Long single-part printing time (e.g., a 100mm titanium alloy part takes 4–8 hours)—unable to meet high-capacity needs (e.g., automotive part mass production).

- 3. High Post-Processing Requirements: Printed parts require support removal (laser cutting), polishing (Ra from 12.5μm to 0.8μm), and heat treatment (stress relief)—post-processing costs account for 30–50% of total costs.

- 4. Size Limitations: Most metal 3D printers have small build volumes (common SLM size: 250×250×300mm); large parts require segmental printing and assembly, reducing accuracy.

- Long-Tail Keywords: Metal 3D printing limitation, metal 3D printing cost analysis, metal 3D printing post-processing process.

5. Common Myths About Metal 3D Printing: Facts to Correct (with Long-Tail Keywords)

5.1 Myth 1: All 3D Printers Can Print Metal—Only Specialized Metal 3D Printers Work

- Wrong Belief: “I can modify my FDM 3D printer (e.g., Creality Ender 3) with a metal nozzle to print metal.”

- Fact: FDM printers have a maximum heating temperature of 400°C, far lower than metal melting points (e.g., titanium alloy melts at 1668°C)—they cannot melt metal. Specialized metal 3D printers (SLM/DMLS/EBM) are required, as their energy sources (laser/electron beam) provide sufficient heat.

- Long-Tail Keywords: Can FDM 3D printers print metal?, specialized metal 3D printer types.

5.2 Myth 2: Metal 3D Printed Parts Are Weaker Than Forged Parts—Industrial SLM Parts Perform Better

- Wrong Belief: “3D printed metal parts are ‘powder-bonded’ and weaker than forged parts.”

- Fact: SLM-printed titanium alloy parts have a density of 99.5%+ and a tensile strength of 900 MPa (comparable to forged parts at 890 MPa). With heat treatment (e.g., hot isostatic pressing, HIP), their fatigue strength can exceed that of forged parts—suitable for high-stress aerospace components.

- Long-Tail Keywords: Metal 3D printed part strength vs. forged part, SLM metal part performance.

5.3 Myth 3: Metal 3D Printing Requires No Post-Processing—Post-Processing Determines Accuracy & Performance

- Wrong Belief: “Metal 3D printed parts are ready to use immediately without further processing.”

- Fact: Printed parts have rough surfaces (Ra 6.3–12.5μm), support structures, and internal stress—they require “support removal → sandblasting → heat treatment → polishing” to meet assembly or usage needs (e.g., medical implants must be polished to Ra 0.8μm to avoid irritating human tissue).

- Long-Tail Keywords: Necessity of metal 3D printing post-processing, metal 3D printing polishing process.

5.4 Myth 4: Only Metal Powders Can Be Used for 3D Printing—Wires & Sheets Work for Specific Technologies

- Wrong Belief: “Metal 3D printing can only use powders, limiting material choices.”

- Fact: Beyond powders, some technologies use metal wires (e.g., WAAM—Wire Arc Additive Manufacturing, using metal wire for large parts) or metal sheets (e.g., LENS—Laser Engineered Net Shaping, using powder or wire)—offering more flexible material options.

- Long-Tail Keywords: Metal 3D printing material types, WAAM metal 3D printing technology.

6. How to Choose Metal 3D Printing Services/Equipment: Key Considerations (with Long-Tail Keywords)

6.1 Define Requirements: Select Metal 3D Printing Technology Based on Part Characteristics

- 1. Part Size: Choose SLM/DMLS for small, high-precision parts (<200mm); choose EBM/WAAM for large parts (>500mm).

- 2. Material Type: Choose SLM/EBM for titanium alloys/high-temperature alloys; choose SLM/Binder Jetting for stainless steel/aluminum alloys; choose DMLS for copper alloys.

- 3. Accuracy Requirement: Choose SLM for accuracy within ±0.1mm; choose DMLS/Binder Jetting for accuracy up to ±0.2mm.

- 4. Batch & Cost: Choose SLM for small batches (1–50 parts); choose Binder Jetting for medium batches (50–500 parts); choose traditional processes for large batches (>1,000 parts).

- Long-Tail Keywords: Metal 3D printing technology selection guide, small-batch metal 3D printing solution.

6.2 Choose Metal 3D Printing Services: Verify 3 Core Capabilities

- 1. Equipment & Material Certification: Ensure the service provider uses industrial-grade equipment (e.g., EOS M290, Concept Laser M2) and provides material quality reports (e.g., RoHS certification, medical-grade biocompatibility reports).

- 2. Post-Processing Capability: Check for heat treatment (HIP, annealing), polishing (CNC, electrochemical polishing), and testing (X-ray inspection, tensile testing) equipment to ensure part performance.

- 3. Industry Experience: Prioritize providers with industry-specific experience (e.g., FDA-certified providers for medical parts, AS9100-certified providers for aerospace parts).

- Long-Tail Keywords: Metal 3D printing service selection criteria, medical-grade metal 3D printing service certification.

6.3 Buy Metal 3D Printing Equipment: Budget & Supporting Requirements

- 1. Budget Range: Entry-level (Binder Jetting): ¥500,000–1,000,000; industrial-grade (SLM): ¥1–5 million; high-end (EBM): ¥5–10 million.

- 2. Supporting Requirements: Prepare powder storage equipment (moisture-proof, oxidation-proof), post-processing workshops (ventilated, high-temperature safe), and professional operators (trained in laser safety and process parameter setting).

- Long-Tail Keywords: Metal 3D printing equipment price, industrial-grade SLM equipment selection.

7. Frequently Asked Questions (FAQ) About Metal 3D Printing

Q1: How much does metal 3D printing cost per part?

A: Costs vary by part size, material, and batch. For small parts (e.g., a 50×50×10mm stainless steel component):

- Small batch (1–10 parts): ~¥500–1,500/part (dominated by setup and post-processing costs).

- Medium batch (50–100 parts): ~¥200–500/part (amortized setup costs).

- Large batch (>1,000 parts): Traditional forging is cheaper (¥50–100/part) than metal 3D printing.

Q2: Can I modify a consumer FDM 3D printer to print metal?

A: No. FDM printers rely on melting thermoplastics (max temp: 400°C), while metals require melting temperatures of 1,000°C+ (e.g., aluminum melts at 660°C, titanium at 1,668°C). Modifying an FDM printer with a metal nozzle cannot generate enough heat to melt metal—specialized metal 3D printers (SLM/DMLS) are required.

Q3: Are metal 3D printed parts strong enough for load-bearing applications?

A: Yes—industrial-grade SLM/DMLS parts meet load-bearing requirements. For example:

- SLM-printed Ti-6Al-4V parts have a tensile strength of 900 MPa (comparable to forged titanium) and are used in aerospace load-bearing brackets.

- DMLS-printed Inconel 718 parts withstand 650°C high temperatures and are used in engine turbine blades (load-bearing under high stress).

Q4: Is post-processing mandatory for metal 3D printed parts?

A: Yes—post-processing is critical for usability. Key steps include:

- Support Removal: Cutting off metal supports (left to prevent part warping during printing).

- Heat Treatment: Annealing or HIP to reduce internal stress (avoids cracking in use).

- Polishing: Sandblasting or electrochemical polishing to improve surface smoothness (Ra from 12.5μm to 0.8μm for medical/automotive parts).

Q5: What is the maximum size of a metal 3D printed part?

A: Most industrial metal 3D printers have build volumes of 250×250×300mm (SLM/DMLS) to 500×500×1,000mm (EBM/WAAM). Larger parts (e.g., 2m aerospace components) require segmental printing and assembly—though this may reduce dimensional accuracy (±0.5mm vs. ±0.1mm for small parts).

Q6: Can metal 3D printing powders be recycled?

A: Yes—unused powder (not melted during printing) can be recycled 5–10 times with proper screening (removing impurities) and drying (reducing moisture). Recycling rates vary by technology:

- SLM: 70–80% powder recovery (strict particle size requirements).

- Binder Jetting: 85–90% recovery (looser powder requirements).

Recycled powder maintains ~95% of the original material properties—reducing material costs by 30–50%.