Answer

Yes, CNC (Computer Numerical Control) machines can cut brass. As a common copper alloy, brass has good machinability. CNC machines can efficiently and precisely complete cutting, milling, drilling and other machining operations on brass by accurately controlling the tool path and cutting parameters.Extended Answer

I. Physical Properties of Brass and Its Adaptability to CNC Machining

Brass is an alloy composed of copper and zinc. Its physical properties such as hardness, ductility, and thermal conductivity directly affect the feasibility and efficiency of CNC machining.

Yes, CNC (Computer Numerical Control) machines can cut brass. As a common copper alloy, brass has good machinability. CNC machines can efficiently and precisely complete cutting, milling, drilling and other machining operations on brass by accurately controlling the tool path and cutting parameters.Extended Answer

I. Physical Properties of Brass and Its Adaptability to CNC Machining

Brass is an alloy composed of copper and zinc. Its physical properties such as hardness, ductility, and thermal conductivity directly affect the feasibility and efficiency of CNC machining.

Hardness and Ductility

The hardness of brass is generally lower than that of steel but higher than that of pure copper. This makes it neither as likely to stick to the tool as soft metals nor to accelerate tool wear as hard metals during cutting. At the same time, brass has good ductility, and long chips are easily generated during machining. It is necessary to optimize chip removal effects through reasonable cutting parameters (such as low feed rate, appropriate cutting depth) and tool design (such as large rake angle, sharp cutting edge).

Thermal Conductivity

The thermal conductivity of brass is better than that of steel but lower than that of aluminum. The heat generated during machining needs to be discharged in a timely manner through coolant or compressed air to avoid workpiece thermal deformation and overheating of the tool.

Chemical Stability

Brass has a stable chemical property at room temperature, but it may oxidize or corrode at high temperatures or in specific media. Therefore, it is necessary to control the cutting temperature during the machining process and select an appropriate coolant (such as water – soluble cutting fluid) to protect the surface quality of the workpiece.

II. Types of CNC Machines and Brass Machining

Different types of CNC machines are suitable for different brass machining requirements. Selecting the right machine is the key to ensuring machining quality and efficiency.

CNC Milling Machine

CNC milling machines mill brass workpieces by rotating the tool, and are suitable for machining complex shapes such as planes, curved surfaces, and cavities. The milling machine needs to be equipped with a high – precision spindle and a rigid bed to withstand the cutting force during brass machining.

CNC Lathe

CNC lathes cut by rotating the workpiece and moving the tool, and are suitable for machining rotary parts such as shafts and discs. The lathe needs to be equipped with a high – precision spindle encoder and tailstock support to ensure the roundness and coaxiality of the workpiece.

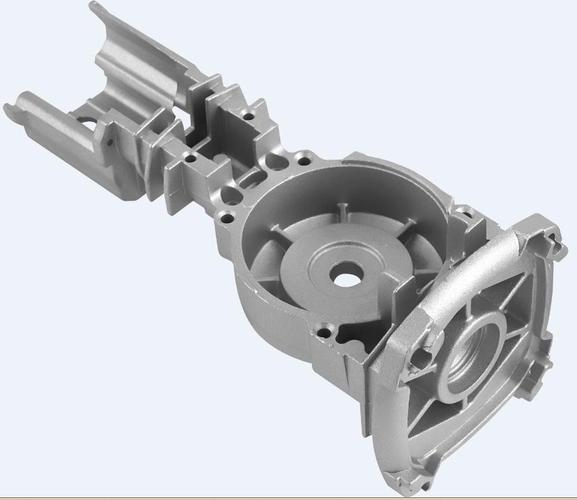

CNC Machining Center

The CNC machining center integrates multiple functions such as milling, drilling, and tapping, and is suitable for multi – process machining of complex parts. The machining center needs to be equipped with an automatic tool changer (ATC) and a high – speed spindle to improve machining efficiency and automation level.

III. Tool Selection and Optimization of Cutting Parameters

The tool material and geometric shape have a direct impact on the brass machining effect, and reasonable cutting parameters are the key to ensuring machining quality and tool life.

Tool Materials

High – Speed Steel (HSS): Suitable for low – speed and small – cutting – volume machining, with low cost but poor wear resistance.

Carbide: It has high hardness and wear resistance, and is suitable for high – speed and large – cutting – volume machining, which is the preferred material for brass machining.

Coated Tools: Such as TiN, TiAlN coated tools, can further improve the wear resistance and anti – adhesion of the tool.

Tool Geometric Shapes

Rake Angle: A larger rake angle (such as 15° – 25°) can reduce the cutting force and cutting temperature, but will reduce the tool strength.

Clearance Angle: An appropriate clearance angle (such as 6° – 12°) can reduce the friction between the tool and the workpiece and improve the surface quality.

Cutting Edge Inclination Angle: A positive cutting edge inclination angle (such as 0° – 5°) can enhance the strength of the tool tip, and a negative cutting edge inclination angle can improve the chip removal effect.

Cutting Parameters

Cutting Speed: The cutting speed of brass is usually relatively high (such as 100 – 300 m/min), but it needs to be adjusted according to the tool material and workpiece hardness.

Feed Rate: A smaller feed rate (such as 0.05 – 0.2 mm/rev) can improve the surface quality, but will reduce the machining efficiency.

Cutting Depth: It is selected according to the workpiece allowance and machine tool rigidity, usually not exceeding 50% of the tool diameter.

IV. Challenges and Solutions in the Machining Process

Chip Control

Long chips are easily generated during brass machining, which may entangle the tool or scratch the workpiece surface. Solutions include:

Using tools with chip – breaking grooves or chip – breakers.

Adjusting cutting parameters (such as reducing the feed rate and increasing the cutting speed).

Using compressed air or coolant to assist chip removal.

Surface Quality

Defects such as scratches and burrs may appear on the surface of brass during machining. Solutions include:

Optimizing the tool path to avoid frequent tool retraction and advancement.

Using finishing tools for the last process.

Adopting post – treatment processes such as polishing or vibratory grinding.

Tool Wear

The zinc element in brass may accelerate tool wear. Solutions include:

Selecting tool materials with better wear resistance (such as coated carbide).

Regularly checking the tool wear situation and replacing worn tools in a timely manner.

Using coolant or lubricant to reduce friction.

V. Application Fields of Brass CNC Machining

Due to its good machinability, corrosion resistance, and aesthetic appearance, brass is widely used in the following fields:

Electronics and Electrical

Used to manufacture precision parts such as connectors, terminals, and heat sinks.

Architectural Decoration

Used to process door handles, lamps, decorative panels, etc.

Automotive Industry

Used to manufacture sensor housings, valves, pipe fittings, etc.

Musical Instrument Manufacturing

Used to process mouthpieces, tone holes, tubes, etc.

VI. Case Analysis: An Example of Brass CNC Machining

Take an electronic connector manufacturer as an example. It uses a CNC machining center to precisely machine brass materials:

Process Flow

Rough Machining: Use a carbide end – mill for rapid material removal, with a cutting speed of 200 m/min, a feed rate of 0.15 mm/rev, and a cutting depth of 1 mm.

Semi – finishing Machining: Use a coated ball – nose mill for surface machining, with a cutting speed of 250 m/min, a feed rate of 0.1 mm/rev, and a cutting depth of 0.5 mm.

Finishing Machining: Use a diamond – coated tool for final surface treatment, with a cutting speed of 300 m/min, a feed rate of 0.05 mm/rev, and a cutting depth of 0.2 mm.

Quality Control

Use a coordinate measuring machine (CMM) to detect the dimensional accuracy of the workpiece (±0.01 mm).

Use a surface roughness tester to detect the surface quality (Ra≤0.4 μm).

Verify the corrosion resistance through a salt – spray test (no rust within 48 hours).

Efficiency Improvement

By optimizing the tool path and cutting parameters, the machining time is reduced by 30%.

The use of an automatic tool changer (ATC) reduces downtime, and the equipment utilization rate is increased to 85%.

VII. Future Development Trends

With the progress of CNC technology and materials science, brass machining will show the following trends:

High – Speed Machining

Further shorten the machining time by increasing the spindle speed and feed rate.

Compound Machining

Combine multiple processes such as milling, drilling, and tapping to complete multi – process machining in one clamping.

Intelligentization

Use Internet of Things (IoT) and artificial intelligence (AI) technologies to achieve real – time monitoring and adaptive adjustment of the machining process.

Green Manufacturing

Adopt environmentally friendly coolants and low – energy – consumption machine tools to reduce the impact on the environment.

Through the above analysis, it can be seen that cutting brass with CNC machines is not only feasible but also has advantages such as high efficiency, precision, and flexibility. With the continuous progress of technology, brass machining will play an important role in more fields.