In the intricate world of modern manufacturing, carbon steel CNC machining stands as a bedrock technology, enabling the production of components that marry exceptional strength with pinpoint accuracy. Carbon steel, prized for its versatility, cost – effectiveness, and wide – ranging mechanical properties, when paired with the precision of Computer Numerical Control (CNC) machining, creates parts that are indispensable across numerous industries. From heavy – duty industrial machinery to critical automotive components, this article explores the technical prowess, material nuances, customization processes, quality control measures, and diverse applications of carbon steel CNC machining, highlighting its role in driving industrial innovation and reliability.

I. Technical Capabilities: Uncompromising Precision in Carbon Steel Machining

(A) Sub – Micron Dimensional Accuracy

Our state – of – the – art CNC machining centers are engineered to achieve remarkable dimensional accuracy, with positioning accuracy reaching ±0.003mm and repeat positioning accuracy of ±0.002mm. For components such as engine crankshafts or hydraulic cylinder rods, where even the slightest deviation can lead to performance issues or failure, these precise tolerances are essential. Advanced on – machine probing systems continuously monitor and adjust the machining process in real – time, ensuring that each carbon steel part adheres to the strictest dimensional specifications. For instance, when machining a 4140 carbon steel crankshaft, we maintain key shaft diameters within ±0.003mm, guaranteeing seamless integration with other engine components and optimal performance.

(B) Complex Geometry Machining

The capabilities of our 5 – axis CNC machining technology open the door to creating carbon steel parts with highly intricate geometries. Whether it’s multi – stepped shafts with internal splines, components with complex cavities for fluid flow, or parts with organic shapes for ergonomic designs, the 5 – axis system executes these designs with unparalleled precision. Compared to traditional machining methods, 5 – axis CNC machining reduces setup – related errors from ±0.01mm to within ±0.003mm, while boosting production efficiency by up to 70%. This is particularly crucial in industries like oil and gas, where components such as valve bodies require both strength and precise internal geometries to ensure proper fluid control.

(C) High – Performance Machining for Carbon Steel’s Characteristics

Carbon steel, with its varying carbon content and mechanical properties, demands specialized machining techniques. Our CNC systems are equipped with high – torque spindles (up to 15,000 RPM) and advanced cutting tools designed specifically for carbon steel. Optimized cutting parameters, including feed rates and speeds, are carefully selected to prevent tool wear and ensure a smooth surface finish. Coolant delivery systems are precisely calibrated to manage heat generation during machining, especially for high – carbon steels that can be prone to work – hardening. For example, when machining a high – carbon steel die block, our high – performance machining approach, combined with carbide – coated tools, achieves a surface finish of Ra 0.8μm, reducing the need for extensive post – machining operations.

II. End – to – End Customization: Tailoring Carbon Steel Parts to Your Exact Requirements

(A) In – Depth Requirement Analysis and Design Conceptualization

When you approach us with your carbon steel part requirements, our team of experienced mechanical and materials engineers begins by engaging in detailed discussions to understand your application. We take into account factors such as the operating environment (temperature, humidity, corrosive substances), the mechanical loads the part will endure (static, dynamic, or cyclic), and any specific functional or aesthetic requirements. Using advanced 3D modeling software and finite element analysis (FEA) tools, we generate multiple design concepts. For a heavy – duty industrial gearbox component, we analyze stress distribution under different load scenarios to optimize tooth profiles and gear ratios, ensuring maximum durability and efficiency. We then work closely with you, iteratively refining the designs based on your feedback, until we arrive at a solution that perfectly meets your performance and budgetary goals.

(B) Strategic Carbon Steel Grade Selection

Based on the finalized design, we recommend the most suitable carbon steel grade for your parts. Different carbon steel grades offer distinct combinations of strength, hardness, ductility, and cost – effectiveness. Here are some commonly used grades and their ideal applications:

Mild Carbon Steel (1018 – 1020): With a low carbon content (0.18 – 0.20%), mild carbon steel offers good formability and weldability. It is commonly used for general – purpose components such as brackets, frames, and simple machine parts. Its relatively low cost makes it an attractive option for applications where high strength is not the primary requirement.

Medium Carbon Steel (1045 – 1050): Medium carbon steel, with a carbon content of around 0.45 – 0.50%, strikes a balance between strength and ductility. It can be heat – treated to enhance its mechanical properties, making it suitable for parts like shafts, gears, and bolts that need to withstand moderate loads. After quenching and tempering, 1045 steel can achieve a tensile strength of up to 600 – 800 MPa.

High – Carbon Steel (1080 – 1095): High – carbon steel, containing 0.80 – 0.95% carbon, is known for its high hardness and wear resistance. It is often used in applications such as cutting tools, springs, and dies. Heat treatment processes like annealing, quenching, and tempering are crucial to optimize its properties and ensure its performance in demanding environments.

Simultaneously, we conduct a comprehensive cost analysis, factoring in material costs, machining complexity, production volume, and any additional finishing or heat – treatment requirements. Our goal is to provide you with a transparent and competitive quote that offers the best value for your investment.

(C) Precision Manufacturing and Order Tracking

Once you approve the design and quote, production commences. You can track the progress of your order in real – time through our dedicated online platform. Our skilled technicians operate the latest CNC turning, milling, and drilling machines, following strict manufacturing protocols to ensure that each carbon steel part meets our exacting quality standards. From raw material procurement, which includes verifying the material’s chemical composition and mechanical properties, to the final machining and finishing operations, we keep you informed at every stage of the process. Whether you order a single prototype or a large – scale production run, we are committed to delivering your parts on schedule, without compromising on quality.

(D) Rigorous Quality Assurance and Timely Delivery

After production, each carbon steel part undergoes a rigorous multi – stage quality inspection. We use coordinate measuring machines (CMMs) with sub – micron accuracy to verify dimensional accuracy, ensuring that all critical dimensions are within ±0.003mm. Surface finish measurements are taken to ensure that the surface roughness meets the required specifications for optimal functionality and aesthetics. In addition, we conduct a series of mechanical tests, including tensile strength testing, hardness testing, and impact testing, to validate the material’s properties and the part’s performance. Non – destructive testing methods, such as ultrasonic testing and magnetic particle inspection, are employed to detect any internal or surface – breaking defects. Only parts that pass all these stringent tests are packaged and shipped to you. We also offer comprehensive after – sales support, addressing any concerns you may have and ensuring that your carbon steel parts perform as expected throughout their lifecycle.

III. Strategic Material Expertise: Carbon Steel Grades for Every Application

(A) Mild Carbon Steel: The Foundation of General – Purpose Manufacturing

Mild carbon steel is the workhorse of many manufacturing applications. Its low carbon content gives it excellent formability, allowing it to be easily shaped through processes such as bending, rolling, and stamping. It is also highly weldable, making it a popular choice for fabricating structures and assemblies. In the construction industry, mild carbon steel is used for building frames, beams, and support structures. In the automotive sector, it is employed for components like brackets, mounts, and some non – critical engine parts. Its affordability and ease of machining make it a practical option for applications where strength requirements are relatively moderate.

(B) Medium Carbon Steel: Balancing Strength and Ductility

Medium carbon steel offers a more robust set of mechanical properties compared to mild carbon steel. Its ability to be heat – treated provides a wide range of customizable characteristics. After quenching and tempering, medium carbon steel can achieve higher tensile strengths, improved hardness, and better wear resistance. This makes it suitable for a variety of applications in the machinery, automotive, and aerospace industries. In machinery, it is used for parts such as axles, crankshafts, and gears that need to transmit power and withstand significant loads. In the automotive industry, medium carbon steel is used for components like connecting rods, steering knuckles, and suspension parts, where a combination of strength and durability is essential.

(C) High – Carbon Steel: Unmatched Hardness and Wear Resistance

High – carbon steel is the go – to material for applications that demand extreme hardness and wear resistance. Its high carbon content enables it to achieve very high hardness levels through heat treatment, making it ideal for cutting tools, dies, and springs. In the metalworking industry, high – carbon steel blades are used in saws, shears, and knives due to their ability to maintain a sharp edge. In the manufacturing of dies for plastic injection molding or metal stamping, high – carbon steel provides the durability needed to withstand repeated impacts and high pressures. Springs made from high – carbon steel can store and release energy effectively, making them suitable for applications such as automotive suspensions and industrial machinery.

IV. Stringent Quality Control: Ensuring Excellence in Every Carbon Steel Part

(A) Raw Material Inspection

All incoming carbon steel raw materials are subject to strict quality checks before entering the production process. We perform spectroscopic analysis to verify the chemical composition of the steel, ensuring that it meets the specified grade standards. Mechanical tests, including tensile strength testing, yield strength testing, and hardness testing, are conducted to assess the material’s mechanical properties. Additionally, we inspect the material for any visible defects such as cracks, inclusions, or surface imperfections. Only raw materials that pass these rigorous inspections are approved for use in manufacturing our carbon steel parts, laying a solid foundation for the quality and performance of the final products.

(B) In – Process Monitoring

Throughout the manufacturing process, we employ advanced monitoring technologies to ensure consistent quality. Real – time sensors continuously monitor key machining parameters, such as cutting forces, spindle speeds, and feed rates. Statistical process control (SPC) techniques are used to analyze the data collected from these sensors, allowing us to detect and correct any potential issues promptly. If any parameter deviates from the set values, our automated systems can adjust the machining process in real – time to maintain the desired quality level. For example, if the cutting force exceeds the predefined limit during the machining of a carbon steel shaft, the system will automatically reduce the feed rate to prevent tool breakage and ensure dimensional accuracy.

(C) Final Product Validation

Before shipping, each carbon steel part undergoes a comprehensive final inspection. In addition to the dimensional and surface finish checks, we conduct a series of functional and non – functional tests. For parts that will be used in fluid – handling systems, we perform leak tests to ensure that there are no leaks or seepages. For parts that will be subjected to cyclic loading, we conduct fatigue tests to simulate real – world usage conditions and verify their durability. We also perform visual inspections to ensure that the parts are free from any surface defects or cosmetic imperfections. Only carbon steel parts that pass all these final validation tests are considered ready for delivery, ensuring that you receive products that are of the highest quality and meet your expectations.

V. Diverse Industry Applications: Carbon Steel Parts Powering Multiple Sectors

(A) Industrial Machinery

In the industrial machinery sector, carbon steel CNC – machined parts are the backbone of many machines. From large – scale manufacturing equipment to heavy – duty construction machinery, carbon steel components provide the strength and durability needed to withstand harsh operating conditions. For example, in metal – working machines, carbon steel shafts, gears, and frames are used to transmit power and support the machine’s structure. In construction equipment such as excavators and loaders, carbon steel parts like boom arms, bucket teeth, and axles are crucial for handling heavy loads and performing demanding tasks. The precision of CNC machining ensures that these parts fit together perfectly, reducing wear and tear and increasing the overall lifespan of the machinery.

(B) Automotive Industry

The automotive industry relies heavily on carbon steel CNC – machined parts for various applications. Engine components such as crankshafts, camshafts, and connecting rods are typically made from medium or high – carbon steel to withstand the high temperatures and mechanical stresses generated during engine operation. In the chassis and suspension systems, carbon steel parts like control arms, steering knuckles, and wheel hubs provide the strength and stability needed for safe and reliable vehicle operation. With the increasing focus on lightweighting in the automotive industry, our precision CNC machining techniques also allow for the optimization of carbon steel part designs, reducing weight without sacrificing strength and performance.

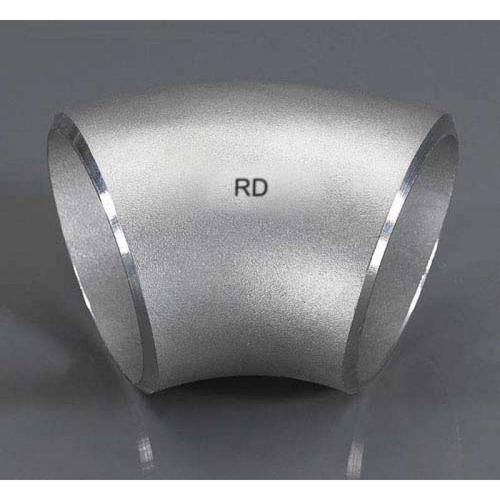

(C) Oil and Gas Industry

In the oil and gas industry, where components are exposed to extreme pressures, temperatures, and corrosive environments, carbon steel parts play a vital role. Pipeline components such as valves, flanges, and fittings are often made from carbon steel, with appropriate coatings or heat treatments to enhance their corrosion resistance. Downhole tools, including drill bits, drill collars, and tubing, are also commonly fabricated from high – strength carbon steel grades to withstand the harsh conditions deep underground. The precision of CNC machining ensures that these parts have the exact dimensions and surface finishes required for proper sealing and operation, preventing leaks and ensuring the safety and efficiency of oil and gas operations.

(D) Energy Sector

In the energy sector, carbon steel CNC – machined parts are used in power generation plants, renewable energy systems, and energy storage facilities. In thermal power plants, carbon steel components such as boiler tubes, turbine shafts, and pressure vessels are essential for the efficient generation of electricity. In renewable energy systems, such as wind turbines and solar power plants, carbon steel parts are used for structural supports, gearbox components, and electrical enclosures. The precision and reliability of our carbon steel CNC – machined parts contribute to the stable operation of these energy systems, helping to meet the growing global demand for clean and sustainable energy.

VI. Frequently Asked Questions (FAQ)

(A) What is the typical lead time for custom carbon steel parts?

The lead time for custom carbon steel parts depends on several factors, including the complexity of the design, the materials used, and the production volume. For simple designs and small – scale production runs (up to 100 pieces), we can typically deliver the parts within 5 – 7 business days. For more complex designs or larger production volumes, the lead time may range from 2 – 4 weeks. However, we also offer expedited services for urgent orders, with lead times as short as 2 – 3 days for selected projects, subject to availability and additional fees.

(B) Can you provide carbon steel parts with specific surface finishes?

Yes, we offer a wide range of surface finishes for our carbon steel parts to meet different application requirements. Common surface finishes include black oxide coating, which provides a thin, protective layer and a decorative black appearance; zinc plating, which offers excellent corrosion resistance; and powder coating, which provides a durable, colorful finish. We can also perform heat treatments such as annealing, quenching, and tempering to modify the material’s properties and surface characteristics. Our engineering team can help you choose the most suitable surface finish based on factors such as the operating environment, corrosion resistance requirements, and aesthetic preferences.

(C) How do you ensure the corrosion resistance of carbon steel parts?

To ensure the corrosion resistance of carbon steel parts, we offer several options. One approach is to apply protective coatings such as zinc plating, electroplating, or powder coating. These coatings create a barrier between the steel and the surrounding environment, preventing moisture and corrosive substances from coming into contact with the metal. Another option is to use corrosion – resistant carbon steel grades, which contain alloying elements such as chromium, nickel, or copper to enhance their resistance to corrosion. Additionally, we can perform heat treatments or surface treatments to improve the surface properties of the carbon steel and increase its corrosion resistance.

(D) What is the minimum order quantity for carbon steel parts?

We do not have a strict minimum order quantity for our carbon steel parts. Whether you need a single prototype for product development or a large – scale production run of thousands of parts, we are happy to accommodate your order. However, please note that for very small order quantities, the unit cost may be relatively higher due to the setup and tooling costs associated with the production process. Our sales team can provide you with a detailed quote based on your specific order requirements, helping you make the most cost – effective decision for your project.

(E) Can you work with my existing carbon steel part design?

Yes, we can work with your existing carbon steel part design. Our team of engineers can review your design files (such as CAD drawings or 3D models) and provide feedback on its manufacturability, performance, and potential areas for improvement. If necessary, we can also perform reverse engineering on your existing parts to create accurate CAD models and ensure that the new parts we produce are identical or improved versions of the original. Whether you need to reproduce an existing part for replacement purposes or want to optimize the design for better performance or cost – effectiveness, we have the expertise and capabilities to meet your needs.

VII. Customer Success Stories

Industrial Machinery Manufacturer

A leading industrial machinery manufacturer was facing issues with the durability of their machine frames. The existing frames, made from a lower – quality steel, were prone to cracking and deformation under heavy loads. They approached us for a solution, and our team recommended using 1045 medium carbon steel and our precision CNC machining services. We designed and manufactured new frames with optimized geometries and enhanced structural integrity. After implementing our carbon steel frames, the machinery’s lifespan increased by 50%, and the number of maintenance and repair incidents decreased significantly. The manufacturer was so impressed with the quality and performance of our parts that they have since made us their exclusive supplier for all their carbon steel component needs.

Automotive Parts Supplier

An automotive parts supplier was developing a new high – performance engine for a sports car and needed precision – machined carbon steel components. We worked closely with their engineering team to design and produce engine crankshafts and connecting rods from 4140 medium carbon steel. Our CNC machining techniques ensured that the parts had the exact dimensions and surface finishes required for optimal engine performance. The high – precision parts reduced engine vibrations and improved power transfer, resulting in a significant increase in the engine’s horsepower and torque.