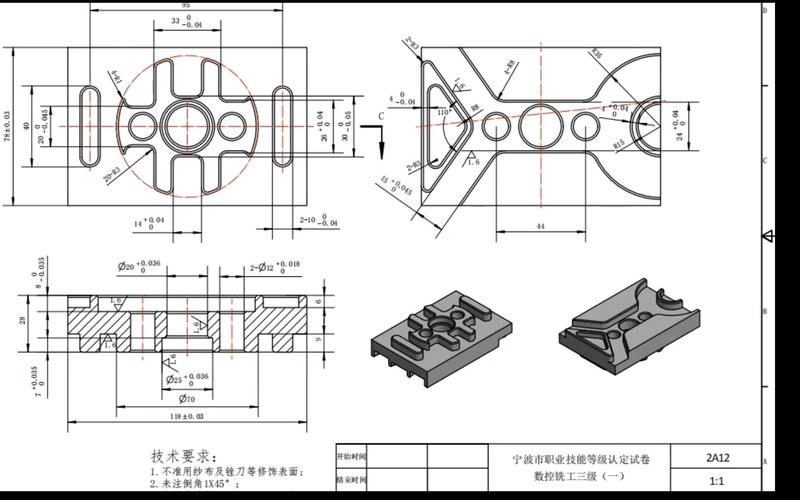

What are the main challenges in CNC titanium alloy machining?

Titanium alloys experience severe work hardening during CNC machining, with 0.05-0.15mm thick surface layers and 40-60HV hardness increase, significantly raising cutting resistance and tool damage compared to stainless steel. Machining…