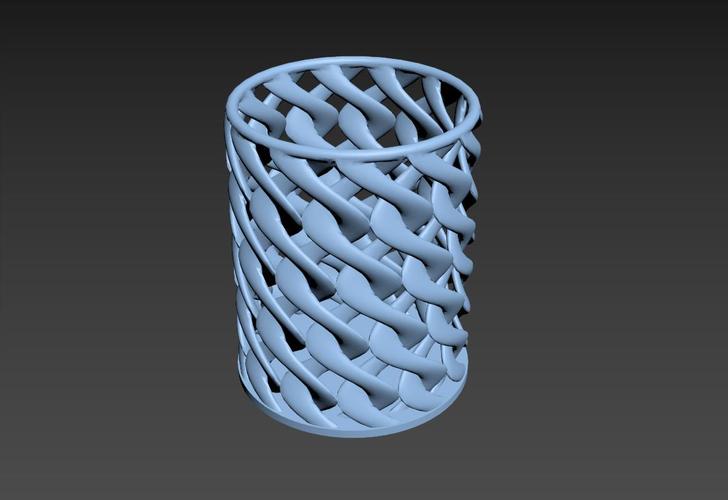

Do 3D printers only use plastic?

Short answer: No, 3D printers can use a wide range of materials beyond plastic, with applications spanning industries from aerospace to healthcare. The choice of material depends on the printing…

Short answer: No, 3D printers can use a wide range of materials beyond plastic, with applications spanning industries from aerospace to healthcare. The choice of material depends on the printing…

3D prints fail mainly due to avoidable setup errors and material inconsistencies. Common culprits include misaligned printer beds causing uneven layer adhesion, incorrect temperature settings leading to warping or stringing, and…

The biggest problem with 3D printing right now is speed vs. quality trade-offs. Most consumer and mid-range printers take hours or even days to create complex parts, and if you…

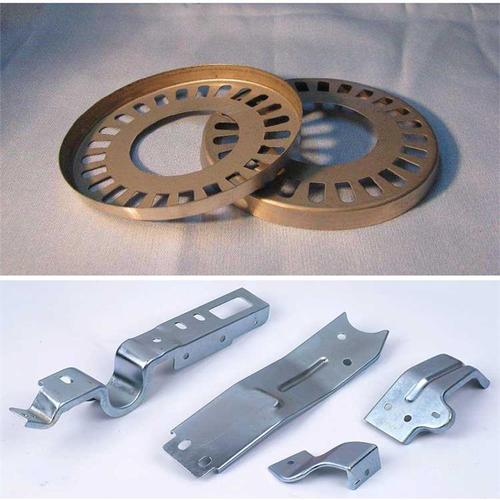

Coining is a precision metal stamping process that uses high pressure to reshape or imprint metal surfaces, creating detailed, crisp features with tight tolerances. Unlike bending or drawing, it compresses…

The “best” gauge for metal stamping depends on application needs, but 16 to 22 gauge (0.5–1.6mm thick) is widely preferred for its balance of formability, strength, and versatility. This range…

Rules of thumb for metal stamping are practical guidelines simplifying design and process decisions, focusing on formability, geometry, and efficiency. Key examples include using a minimum bend radius of 1×…

The “best” material for metal stamping depends on application needs, but low-carbon steel (mild steel) is widely favored for its balance of formability, strength, cost, and versatility. It handles bending,…

Metal stamping difficulty varies widely, from straightforward for simple parts (e.g., washers) to highly challenging for complex, high-precision components. Factors like material hardness, part complexity (thin walls, tight tolerances), and…

The stamping procedure is a systematic manufacturing process that shapes flat metal sheets into desired parts using dies and presses. It involves a sequence of steps: material preparation, die setup,…

Metal stamping is a versatile manufacturing process used to shape flat metal sheets into precise, complex parts via dies and presses. It creates components with consistent dimensions, from simple brackets…