What is vacuum casting?

Vacuum casting is a precision manufacturing process that produces metal or plastic parts by pouring molten material into a mold within a vacuum environment. By removing air and gases from…

Vacuum casting is a precision manufacturing process that produces metal or plastic parts by pouring molten material into a mold within a vacuum environment. By removing air and gases from…

Anodization is an electrolytic process that converts a metal surface into a durable, porous oxide layer, primarily used to enhance corrosion resistance, wear resistance, and aesthetic appeal. By immersing the…

Steel cannot be effectively or practically anodized for industrial purposes. Unlike aluminum, which forms a thick, durable oxide layer via anodization, steel’s anodic oxidation produces a thin, porous, and unstable…

The minimum bend radius (MBR) for sheet metal is the smallest inner radius achievable during bending without causing material cracking, tearing, or excessive deformation. It depends on material ductility, thickness,…

The rule of thumb for sheet metal refers to practical design and processing guidelines accumulated from experience, simplifying complex engineering calculations into easy-to-remember principles—like “bend radius ≥ material thickness” or…

The five key sheet metal operations are shearing, bending, punching, drawing, and forming. Shearing cuts sheets to size; bending shapes them into angles; punching creates holes or features; drawing forms…

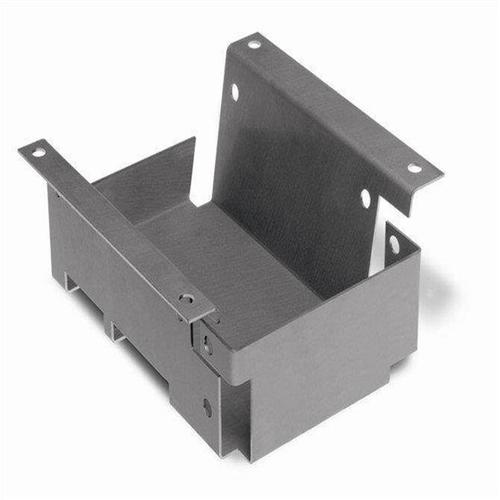

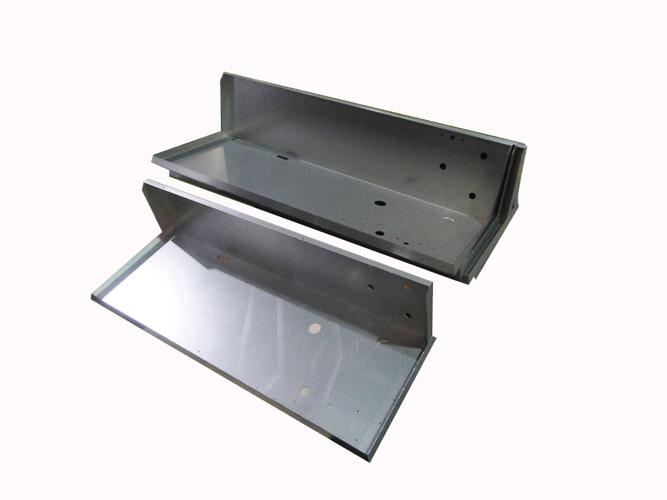

The core difference between sheet metal parts and machined parts lies in raw material form and processing methods: sheet metal parts are “shaped” from thin metal sheets through cutting, bending,…

The 4T rule is a core guideline in sheet metal design to ensure bending accuracy, requiring functional features (e.g., holes, bosses) to be at least 4 times the material thickness…

CNC milling is a subtractive manufacturing process where computer-controlled milling machines use rotating cutting tools to remove material from a workpiece, shaping it into precise 2D or 3D geometries. It…

H codes in CNC programming are tool length offset codes that specify compensation values for differences in tool lengths. They work with G codes (e.g., G43, G44) to adjust the…