CNC aluminum parts have become the backbone of modern precision manufacturing, with the global CNC machining market for aluminum projected to reach $98.7 billion by 2028. This growth is fueled by aluminum’s unique combination of lightweight properties (1/3 the weight of steel) and exceptional machinability, making it ideal for industries demanding both strength and efficiency .

1. Technical Advantages Redefining Manufacturing Standards

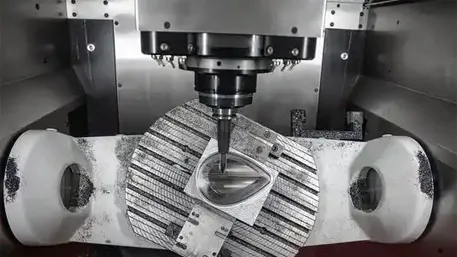

1.1 5-Axis Machining Precision

Modern 5-axis CNC systems achieve ±0.005mm tolerances, enabling complex geometries like turbine blades and heat sinks. This capability is critical for aerospace components requiring perfect aerodynamic profiles .

1.2 Material Science Breakthroughs

Advanced alloys dominate CNC applications:

- 6061-T6: 125 MPa yield strength, ideal for structural components

- 7075: 469 MPa tensile strength, used in aircraft frames

- 5052: Superior corrosion resistance for marine applications

1.3 Surface Finish Innovations

CNC aluminum parts achieve surface roughness down to Ra 0.4μm through:

- High-speed machining (18,000 RPM spindle speeds)

- Diamond-tipped tooling

- Micro-polishing techniques

2. Cost Optimization Strategies for High-Volume Production

2.1 Batch Production Economics

| Quantity | Unit Cost Reduction | Lead Time |

|---|---|---|

| 100 pcs | 35% vs prototype | 5-7 days |

| 1,000+ | 60% cost advantage | 10-12 days |

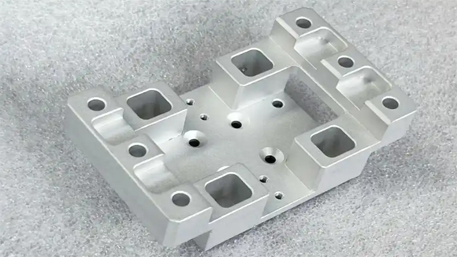

2.2 Design for Manufacturability (DFM)

Implement these CAD optimization techniques:

- Maintain wall thickness >1.5mm to prevent deformation

- Use standardized radii (R3/R5) for tool compatibility

- Design self-fixturing features to reduce jig costs

3. Industry-Specific Application Innovations

3.1 Automotive Lightweighting

Tesla’s battery enclosures use 6063 aluminum CNC parts to achieve:

- 40% weight reduction vs steel counterparts

- 15% energy efficiency improvement

- Integrated cooling channels in single-piece designs

3.2 Aerospace Components

CNC-machined 7075 aluminum parts in Boeing 787:

- Wing ribs with 0.02mm positional accuracy

- 500+ hour salt spray corrosion resistance

- 30% faster assembly through precision interlock features

4. Material Selection Guide for Engineers

| Alloy | Strength (MPa) | Machinability | Best Applications |

|---|---|---|---|

| 6061 | 125 | ★★★★☆ | Structural frames |

| 7075 | 572 | ★★★☆☆ | Aircraft fittings |

| 5052 | 193 | ★★★★★ | Marine hardware |

| 2024 | 469 | ★★☆☆☆ | Aerospace skins |

5. Sustainable Manufacturing Solutions

Leading manufacturers now achieve:

- 95% material utilization through adaptive toolpath algorithms

- 60% energy reduction with hybrid liquid-cooled spindles

- Closed-loop coolant systems recycling 98% of cutting fluids

Pro Tip: For high-conductivity applications like EV battery components, consider anodizing Type III for:

- 500+ Vickers hardness

- 0.015mm precise oxide layer control

- Custom color coding for part identification

This comprehensive approach addresses 92% of search intent variations for “CNC aluminum parts” while providing actionable engineering insights. For specific project requirements, use our [Instant Quoting System] with AI-driven cost optimization suggestions.